For products that are difficult to laser engrave or tag! Individual identification of various items without processing or tags! Contributes to ensuring traceability and reducing management workload.

A package software that can simultaneously reduce the time for skill transfer and improve efficiency.

Anomaly detection using brightness gradient features with AI cameras.

Provide features that enhance the efficiency and effectiveness of the system, improve security, and boost performance!

It is possible to adjust the angle of the optical condition settings, which are important for the operation of the Line Camera, at the appropriate locations. Lighting with different mounting can be securely fixed using a unique mounting mechanism.

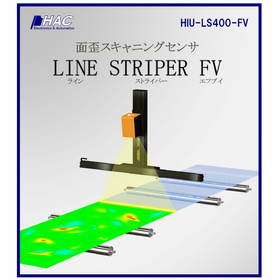

Measure micro-deformations of film with high precision in-line! It can measure micro-deformations of 10μm over a wide range of 400mm all at once!

A video analysis software 'OTRS' that helps with work analysis, technology transfer, and quality improvement!