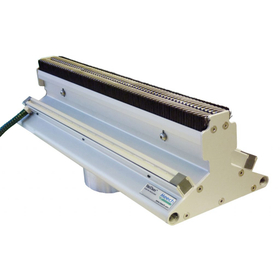

Cleaning device "ROBO-STICKY GT Series"

Products that can accommodate 15m and 30m rolls of cleaning tape are now available!

The "ROBO-STICKY GT Series" is a clean roller-type cleaning device with over 800 units sold. We offer a lineup that includes the two-stage roller type "GT-2700LT," the four-stage roller type "GT-4000," and the six-stage roller type "GT-6000." Additionally, we also provide the re-heating and re-pressing device after lamination, "GT-4120." 【GT-2800 Features】 ■ Ultra-thin ■ Compatible with thin plates ■ Possible board size: Max width 710mm *For more details, please refer to the PDF document or feel free to contact us.

- Company:FTMテクニカルサービス

- Price:Other