Metal and resin precision machining contract services

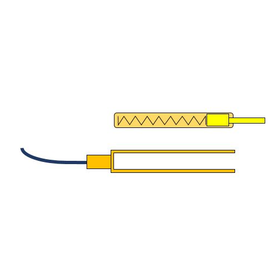

We provide advanced processing technology cultivated through the production of contact probes and various inspection jigs.

Our company is a manufacturer of contact probes used for inspecting various electronic components, as well as inspection fixtures that utilize these probes. The technology required in these fields is at an extremely high level, characterized by "ultra-high precision" and "ultra-fine" specifications. Our technology, which has been refined over many years to meet these demands, has solved various challenges not only in inspection-related areas but also across a wide range of applications. We also offer this technology as a processing contract service. *For more details, please download the PDF or contact us.*

- Company:精研 本社

- Price:Other

![Semiconductor Testing [Contact Probes, IC Sockets, Probe Cards]](https://image.mono.ipros.com/public/product/image/6d6/2000410005/IPROS91145408194563330894.jpeg?w=280&h=280)