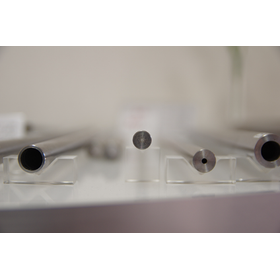

[Production Example] SUS304

Suitable for use in humid areas such as food/chemical industry equipment, machinery, faucets, and sinks!

We would like to introduce examples of processing SUS304 by our company. It is a material with very poor thermal conductivity, making it prone to tool breakage due to the difficulty in dissipating machining heat. Additionally, distortion of the stainless steel is likely to occur at high temperatures during processing, which is why it is considered a difficult-to-cut material. If excessive load is applied during processing, the structural organization changes, leading to work hardening, which is also a characteristic of this material. Therefore, the selection of cutting tools and how to manage heat during processing are key points in machining. [Reference Materials] ■SUS304 ■SUS304L (Austenitic stainless steel) *For more details, please refer to the related links or feel free to contact us.

- Company:新栄製作所

- Price:Other

![[Production Example] SUS304](https://image.mono.ipros.com/public/product/image/308/2001469927/IPROS00474616010405724454.png?w=280&h=280)

![[VA/VE Case] Cost Reduction by Changing Material to SUS443](https://image.mono.ipros.com/public/product/image/2071035/IPROS10763568295024552135.png?w=280&h=280)

![[Case Study] Cost Reduction through Appropriate Selection of 2B Material and KD Material](https://image.mono.ipros.com/public/product/image/2071035/IPROS14871350016759600943.png?w=280&h=280)