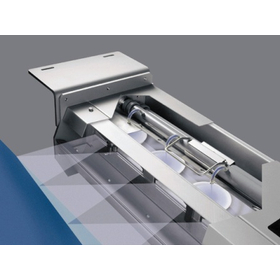

[Machine Parts Coating] *Examples of wear patterns and evaluation results are also introduced!

New functions for mechanical parts! By modifying the surface, we can meet various demands. We are introducing case studies that incorporate actual requests we have received.

Introducing coatings for mechanical parts. Industrial products and their materials and components require various functions, characteristics, and performance simultaneously, depending on the environment and load in which they are used. Adhesive wear is effectively addressed by coatings with low affinity to the counterpart material and control of surface properties. By modifying the very surface, it is possible to impart various functions and characteristics, thereby meeting diverse requirements. 【Wear Modes of Mechanical Parts】 ■ Adhesive Wear: Coatings with low affinity to the counterpart material and control of surface properties ■ Abrasive Wear: Surface hardness increase with Jcoat + α treatment ■ Corrosive Wear: Selection of coatings suitable for corrosive environments ■ Fatigue Wear: Neo-Slick, CrN, etc. *For more details, please refer to the catalog or feel free to contact us.

- Company:日本コーティングセンター(JCC)

- Price:Other

![[Machine Parts Coating] *Examples of wear patterns and evaluation results are also introduced!](https://image.mono.ipros.com/public/product/image/f81/2000294326/IPROS89603296294084428085.png?w=280&h=280)

![[Mold Coating] *Introducing examples of resin molds and die casting.](https://image.mono.ipros.com/public/product/image/ff6/2000294332/IPROS48531298550637013746.jpeg?w=280&h=280)