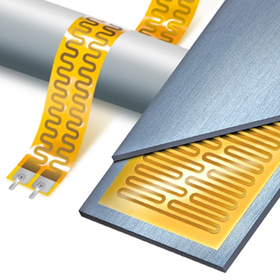

Reikem's self-regulating heater for warming pipes

Reikem is top-class in the world! It is Reikem's self-regulating pipe heater that can warm pipes with low power consumption by running a heater alongside them.

Our company is a licensed sales and engineering agent for Raychem's self-regulating pipe heaters (auto-trace heaters), supporting energy-saving, cost-reduction, and CO2 reduction for pipe and tank heating systems. The Raychem brand is recognized for its technical leadership as the inventor of self-regulating heating cables. Additionally, Raychem's pipe heater cables adjust their output according to surrounding and process conditions, accurately delivering the right amount of heat to the necessary location at the required time, making them ideal for pipe and tank heat management systems. 【Features】 ■ Authorized primary engineering agent for Raychem, handling self-regulating pipe heaters and more ■ Supporting energy-saving, cost-reduction, and CO2 reduction for pipe and tank heating systems *For more details, please refer to the PDF document or feel free to contact us.

- Company:西都電機

- Price:Other

![[Useful Information] What is annealing? Quality improvement through far-infrared heating.](https://image.mono.ipros.com/public/product/image/d15/2001487353/IPROS85835633781920258142.png?w=280&h=280)