Ultrasonic welding machines use frictional heat generated by ultrasonic vibrations to join materials such as plastic and vinyl.

The ultrasonic welding machine is an industrial device that utilizes friction heat generated by ultrasonic vibrations to quickly and easily weld materials such as plastic and vinyl.

It allows for safe welding with simple operation and can be used for various applications, including blister packs, food packs, non-woven fabrics, and thin resin parts. The welding quality and strength may vary depending on the type and thickness of the material.

● The handpiece has been miniaturized, achieving a palm-sized design that is among the smallest in the industry for handheld ultrasonic welding machines.

● The handpiece features a straight shape that is easy to mount on dedicated machines or robots, and its structure supports air cooling, enabling stable continuous use despite its compact size.

● The tip (horn) can be manufactured in various shapes according to customer requests (sold separately).

*Note: For handheld compact ultrasonic welding machines, as of October 2019, according to Suzuki's research.

*Note: When mounted on dedicated machines or robots, an external input/output unit (sold separately) is required. Handpiece mounting fixtures, air fittings, air hoses, and air supply equipment are also required separately.

*Note: Depending on the shape and other factors, it may not be possible to meet all requests.

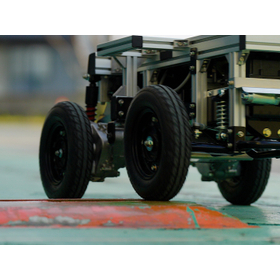

![[Case Study of Electric Mobility Base Unit] Civil Engineering/Construction Robot](https://image.mono.ipros.com/public/product/image/fcd/2001125951/IPROS9429229160498024013.PNG?w=280&h=280)

![[Case Study of Electric Mobility Base Unit] Agricultural Robot](https://image.mono.ipros.com/public/product/image/b04/2001125952/IPROS2115171640253203107.png?w=280&h=280)