46~72 item / All 72 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online46~72 item / All 72 items

It is suitable for soft bond applications. The copper coating layer reduces high-temperature corrosion through the retention of diamond abrasives, effectively extending the tool's lifespan.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The titanium coating layer enhances the retention of synthetic diamond abrasives in the bond matrix, alleviates thermal shock, prevents oxidation and graphitization of the diamond abrasives, and extends the product's lifespan.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a nickel alloy coated product. The surface of the groove structure can enhance the holding power of synthetic diamonds in the coating layer and bond matrix. The composite coating product reduces the amount and wear of diamond abrasives, extending the tool's lifespan.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a spiked nickel alloy coated product. The coating layer enhances the holding power of synthetic diamond abrasives in the bond matrix, alleviates thermal shock, and prevents oxidation and graphitization. The spiked nickel alloy on the surface increases the weight of the diamond abrasives, improves sharpness, enhances cutting efficiency, and extends the tool's lifespan.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features: In response to customer needs, we offer various types of micron coatings. The coating layer enhances the performance of diamonds.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Large single crystal diamonds are synthesized in a high-temperature and high-pressure environment through strict control of temperature and pressure. They are suitable for processing non-ferrous metal and non-metal materials such as cutting tools, wheel dressing, special knives, polishing tools, and wire dies. The products come in different sizes and thicknesses, with sizes ranging from 2.0 mm to 8.0 mm in length and thicknesses from 0.8 mm to 1.2 mm. Large single crystal grades include CMD20, CMD40, CMD60, CMD80, CMD90, and CMD100. Large single crystal sizes are 4.2, 4.0, 3.8, 3.6, 3.4, 3.2, 3.0, 2.8, 2.6, 2.4, 2.2, 2.0, 10/12, 12/14, 14/16, 16/18, and 18/20.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PCD cutting tool blanks are manufactured through the sintering of micron diamond abrasives and hard alloys, as well as polycrystalline diamond abrasives and hard alloys, in environments of ultra-high temperature and ultra-high pressure. The hardness and wear resistance of this product are roughly the same as that of natural diamond, and its toughness is almost similar to that of hard alloys. It is ideal to use these materials for manufacturing long-lasting and high-efficiency tools. Polycrystalline diamond cutting blanks have different physical characteristics, making them suitable for special applications and capable of meeting various customer requirements.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PCBN blanks, designed specifically for cutting tools, are superhard materials made from a compound of polycrystalline CBN and hard alloys, sintered under ultra-high temperature and ultra-high pressure conditions. The hardness, wear resistance, and thermal stability of PCBN blanks are roughly the same as CBN, and their toughness is almost comparable to that of hard alloys. Due to their high hardness, they are ideal materials for machining cutting tools for ferrous and non-ferrous metals. PCBN blanks enable high-speed cutting and are suitable for continuous processing. When used for dry cutting, they operate quietly and are environmentally friendly. They are applicable for milling, boring, and reaming of materials with hardness HRC 45-65 (for example, cast iron, hard bearing steel, nickel and chromium alloys, etc.). So far, our company has been able to provide round, square, 80% rhombus, and triangular shapes.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PDC is produced through the sintering of diamond and WC using high-temperature and high-pressure technology. PDC "absorbs" the advantages of diamond and WC, possessing high wear resistance and excellent impact strength. It is applicable in the manufacturing of various types of drilling tools (for example: oil, geological, and engineering drilling bits, etc.). Our standard shape is round, but it is also possible to manufacture according to customer requirements.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the same high-temperature and high-pressure environment, TSP has difficulty bonding with polycrystalline diamond and PCD products. TSP possesses wear resistance and thermal stability, and when temperatures reach 1200 degrees, the adhesive properties of TSP itself are inert, so the coefficient of TSP and diamond is the same. TSP is suitable for milling bits and oil drilling bits. Compared to natural diamonds, TSP is lower in cost and has a higher work rate.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PCD dice blanks are manufactured in high-temperature and high-pressure environments. Through the interconnection of high-quality diamonds, they achieve a higher hardness, and their wear resistance and thermal conductivity are roughly the same as natural diamonds, while their toughness is almost comparable to tungsten alloys. They are optimal as manufacturing materials for high-precision and long-lasting dies. Our PCD comes in two series: the BCD series and the TSP series.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Diamond compounds come in two types: oil-soluble and water-soluble. Oil-soluble compounds are suitable for lapping and polishing hard materials. Water-soluble compounds are used for polishing and processing surveying instruments, as well as for polishing sealed parts made from hard and brittle materials (such as glass, ceramics, and gemstones).

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Large single crystal diamonds are synthesized in a high-temperature and high-pressure environment through strict control of temperature and pressure. They are suitable for processing non-ferrous metal and non-metal materials for cutting tools, wheel dressing, special knives, polishing tools, wire dies, and more. The sizes range from 2.0 mm to 8.0 mm in length and from 0.8 mm to 1.2 mm in thickness. Grades: SCD11, SCD12, SCD13; SCD21, SCD22, SCD23; SCD31, SCD32, SCD33. Sizes: 3010, 3012, 3510, 3512, 4010, 4012, 4510, 4512, 5010, 6010, 7010, 8010.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Chromium has excellent wettability and affinity, so it forms chromium carbide on the surface of diamond abrasives through sintering. This chromium carbide enhances the retention of diamond abrasives and increases the bonding strength between the abrasives and the bond. Furthermore, the chromium coating improves the strength and corrosion resistance of the diamond abrasives.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The silicon layer enhances the thermal stability and wear resistance of diamond abrasives, preventing the corrosion of the metal iron. Additionally, the chemical layer improves the bonding and abrasive retention, as well as thermal stability, thereby extending the tool's lifespan and improving processing quality.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company can provide two types of single crystal diamond plates. One is produced through a method called Chemical Vapor Deposition (CVD), and the other is produced through a method called High Pressure High Temperature (HPHT). Our single crystal diamonds are widely used in cutting tool applications such as inserts, end mills, and dies, as well as in dresser applications. Our products are primarily diamonds with a crystal orientation of 100, but we can also provide single crystal diamonds SCD-WD (with a crystal orientation of 111) for die applications.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Single crystal diamonds are synthesized using high-temperature and high-pressure technology, with strict control over temperature and pressure. They are widely applied in cutting tools for non-ferrous metals and non-metal materials, wheel dressers, special knives, vanishing tools, wire dies, and more. The products come in various sizes and thicknesses, with standard sizes: the length of the edge ranges from 2.0 mm to 8.0 mm, and the thickness can be provided from 0.8 mm to 1.2 mm. Sizes range from an edge length of 2.0 mm to 8.0 mm, and thickness from 0.8 mm to 1.2 mm. Grades: SCD11, SCD12, SCD13; SCD21, SCD22, SCD23; SCD31, SCD32, SCD33 Sizes: 3010, 3012, 3510, 3512, 4010, 4012, 4510, 4512, 5010, 6010, 7010, 8010

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PCD sintered bodies are products that have been sintered with micron diamond abrasives on a hard substrate using high-temperature and high-pressure technology. PCD sintered bodies are cutting tool materials that combine the excellent properties of natural diamonds, such as high hardness, wear resistance, and low friction coefficient, with the impact strength characteristics of the hard substrate. To meet various applications, our company can provide PCD sintered bodies in different shapes and sizes.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PCBN sintered bodies are composite superhard materials sintered with polycrystalline CBN on a superhard substrate using high-temperature and high-pressure technology. PCBN sintered bodies combine the excellent high hardness, wear resistance, and thermal stability of CBN with the high toughness of the superhard substrate, making them ideal materials for cutting tools for hard iron and non-ferrous metals.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features: Black single crystal, irregular semi-blocky shape, medium strength, good cutting ability, combining grinding efficiency and service life. Applications: Used for resin bond and vitrified bond applications. PS: The CBN series can also be coated with titanium, nickel (60wt%), copper (50wt%), etc. Size: 50/60~325/400

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features: Transparent amber-colored single crystals with irregular shapes, medium strength, and good cutting ability. Applications: Suitable for electroplated bond applications due to its sharp edges and unique micron crushing properties. It is also suitable for resin bond applications. PS: The CBN series can also be coated with materials such as titanium, nickel (60wt%), and copper (50wt%).

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Generally, the surface of the RGD series is coated with Ni (30wt% or 55wt%) and copper (50wt%). The coating layer reduces high-temperature corrosion through the retention of diamond abrasives, effectively extending the tool's lifespan. Mesh: 50/60-500/600

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features: Low-quality diamond abrasives, yellow crystals, rough surface, low strength and toughness. Applications: Suitable for vitrified bond and metal bond low-load applications. Sizes: 60/80~500/600 PS: Coating is also possible.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features: It combines regular and irregular crystals, providing intermediate toughness and intermediate strength. Applications: It is used for various purposes in the glass and ceramics industries and is widely applied in metal bond applications. PS: Coating is also possible. Mesh: 60/80-400/500

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

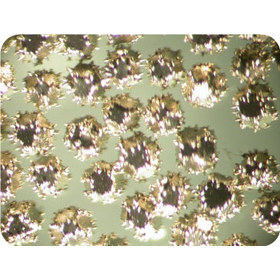

Features: Medium to high-grade metal bond abrasives with regular hexagonal or octahedral crystals, offering toughness, impact resistance, and thermal stability. Applications: Widely used for processing materials that withstand medium to high loads (such as glass, ceramics, quartz, etc.) and for metal bond applications. PS: Coating is also possible. Sizes: 60/80 to 500/600.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features: Complete cubic and octahedral diamond abrasives with uniform shapes and very pure transparent crystal interiors. They possess high impact resistance and excellent thermal stability. Applications: Suitable for metal bond applications used under extremely harsh conditions. Applicable for high-load cutting, drilling, and polishing. PS: Coating is also possible. Sizes: 60/80 to 500/600.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features: With top diamond abrasives, it has a perfect cubic or octahedral shape, and the interior of the transparent crystal is very pure. MSD100 not only has good wear resistance but also exhibits excellent impact resistance and thermal stability. Applications: Suitable for cutting and drilling applications used in extremely harsh environments. It is applicable for the manufacturing of high-quality blades, wire saws, and core bits. PS: Coating is also possible. Size: 20/25 to 60/70

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration