1~33 item / All 33 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile1~33 item / All 33 items

Filter by category

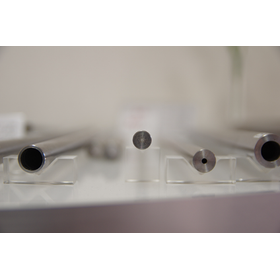

This case study involves mass production of parts for semiconductor manufacturing equipment, specifically focusing on deep hole machining with a diameter of φ1.5mm. Despite the long length condition of approximately 180mm, we have established stable machining conditions through gun drilling, maintaining a production rate of over 200 pieces per day. Due to the small diameter and high L/D ratio, issues such as vibration during machining and variations in inner diameter are challenges; however, we have stabilized inner diameter accuracy by optimizing setup methods and cutting conditions. No defects have occurred in the full inspection, ensuring both reproducibility and supply stability for mass-produced parts. 【Features】 ■ Mass production achievements for φ1.5mm fine diameter deep holes ■ Stable inner diameter accuracy even under long length conditions ■ Capable of continuous production exceeding 200 pieces per day ■ Quality control system through full inspection *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This service is a machining service that focuses on deep hole processing with a diameter of less than φ3mm, which is required for parts in the medical and precision fields, and provides technical consultation from the design consideration stage. As the diameter decreases and the length increases, it becomes more challenging to determine the feasibility of machining and set tolerances, so we organize machining methods and dimensional conditions from the stage when the drawings are not finalized. Utilizing setup and machining know-how that takes into account core misalignment and straightness, we offer proposals for machining methods that are practical and feasible. We also have experience with φ0.5mm class parts, but we consider them on a case-by-case basis depending on the conditions, emphasizing realistic feasibility judgments. We can also accommodate feasibility checks for prototypes and small lots. **Features** - Specializing in deep hole machining with a diameter of less than φ3mm - Technical consultation available even when drawings are not finalized - Proven machining experience in the medical and precision fields - Honest proposals that prioritize feasibility "This service is designed for consultations starting from the stage of wanting to confirm whether machining is possible." *For more details, please download the PDF or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This service is a machining service that combines in-house equipment and an outsourcing network based on deep hole machining technology using gun drilling, allowing for comprehensive support from general cutting processes to subsequent operations. We perform high-precision machining of fine deep holes starting from φ0.5mm and long parts in-house, while collaborating with established partners for larger diameter machining, complex shapes, heat treatment, and polishing processes that exceed our capabilities. We manage the entire process and establish machining routes tailored to drawing requirements and usage conditions. We can also accommodate the procurement of long pipes, secondary processing, and BTA deep hole machining for diameters of 30mm or more. 【Features】 ■ Consistent support through in-house deep hole machining and outsourcing collaboration ■ Consolidated process management from cutting to heat treatment and polishing ■ Consultation available for long materials and large diameter machining ■ Flexible support from prototyping to mass production *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the production of guide shafts for medium-diameter deep holes used in precision devices, FA equipment, and analytical instruments. In this case, there were challenges such as difficulty in chip removal and heat management in stainless steel deep holes, as well as the requirement for shoulder machining precision. However, through our company's efforts, we were able to achieve improvements in device performance, reduction in adjustment work, and enhancement of yield. Our company has many years of experience and advanced technology in the field of deep hole machining and gun drilling. Utilizing our advanced gun drilling technology that enables precise deep hole machining, we provide high-quality machining services tailored to our customers' needs. 【Case Overview】 ■Industry: Precision devices / FA equipment / Analytical instruments ■Part Information: SUS303, φ6.4×223mm shoulder hole, concentricity 0.06mm ■Challenges: - Difficulty in chip removal and heat management in stainless steel deep holes - Requirement for shoulder machining precision ■Provided Value: High precision for both deep holes and shoulder holes. Stable machining with zero seizure. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of manufacturing deep hole components made of heat-resistant steel used for gas venting in resin molds. In this case, there was a challenge of high machining load on heat-resistant steel and the need for high-precision processing of the tip shape. However, through our company's efforts, we achieved stable quality, reduced gas accumulation, and improved molding cycles. Our company has many years of experience and advanced technology in the fields of deep hole machining and gun drilling. Utilizing advanced gun drilling technology that enables precise deep hole machining, we provide high-quality processing services tailored to our customers' needs. 【Case Overview】 ■ Industry: Resin Molds ■ Part Information: SKD61, φ4.6×169.2mm, tip SR shape, deep hole machining ■ Challenge: High machining load on heat-resistant steel / Need for high-precision processing of the tip shape ■ Provided Value: Deep hole machining that suppresses thermal deformation / Achieving tip shape within ±0.01mm ■ Technical Points: Tools specifically for heat-resistant steel, high-pressure coolant, temperature rise suppression machining *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of deep hole machining on both sides of positioning shafts used in automotive molds and jigs. In this case, there were challenges such as the tendency for misalignment during dual-side machining and significant effects of thermal deformation. However, through our company's efforts, we were able to achieve improvements in assembly accuracy, stability of jig lifespan, and yield rate. Our company has many years of experience and advanced technology in the fields of deep hole machining and gun drilling. Utilizing our advanced gun drilling technology, which enables precise deep hole machining, we provide high-quality machining services tailored to our customers' requirements. 【Case Overview】 ■ Industry: Automotive molds/jig devices ■ Part Information: S45C, φ3×130mm dual-side machining, tolerance ±0.01 to 0.02mm ■ Challenges: Tendency for misalignment during dual-side machining / significant effects of thermal deformation ■ Provided Value: Established a stable machining process with eccentricity of 0.02 to 0.03mm and mass production capability ■ Technical Points: Multi-stage centering, optimization of dual-side machining sequence, warpage correction technology *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the production of shouldered long holes processed inside precision shafts for the food, medical, and analytical equipment sectors. In this case, there were challenges related to the unique issues of galling and maintaining precision with stainless steel. However, through our company's efforts, we were able to achieve improvements in equipment precision, reduction of vibrations, and ease of assembly. Our company has many years of experience and advanced technology in the fields of deep hole processing and gun drilling. Utilizing advanced gun drilling technology that enables precise deep hole processing, we provide high-quality machining services tailored to our customers' requirements. 【Case Overview】 ■ Industry: Precision Equipment / Food Machinery / Medical Devices ■ Part Information: SUS303, φ12.7×208.7mm shouldered, concentricity 0.02mm ■ Challenge: Difficulty in maintaining precision and galling unique to stainless steel ■ Provided Value: Maintained high precision with concentricity of 0.02mm and anti-galling processing ■ Technical Points: Optimization of cutting conditions for stainless steel, heat dissipation control, and shoulder finishing processes *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study on the processing of center holes in long shafts used as oil and cooling passages inside industrial machinery. In this case, there were challenges such as the long, thin diameter being prone to bending and difficulties in internal heat and chip discharge. However, through our company's efforts, we achieved stable flow rates, reduced assembly man-hours, and high reliability. Our company has many years of experience and advanced technology in the field of deep hole processing and gun drilling. Utilizing advanced gun drilling technology that enables precise deep hole processing, we provide high-quality machining services tailored to our customers' needs. 【Case Overview】 ■ Industry: Industrial Machinery (Hydraulic and Cooling Mechanisms) ■ Part Information: DAC material, φ3×351mm, L/D=117, concentricity 0.15 to 0.19mm ■ Challenges: Long, thin diameter prone to bending / Difficulties in internal heat and chip discharge ■ Value Provided: Successful penetration even with L/D over 100 / Achieved exit eccentricity of less than 0.2mm ■ Technical Points: Feed control, high-pressure coolant, tool life monitoring, dedicated deep hole equipment *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce a case study of the production of ultra-fine diameter deep hole components used in cooling channels and gas venting within molds in high-temperature environments. In this case, there were challenges due to a high risk of breakage from the ultra-fine diameter and difficulties in ensuring straightness due to the deep holes. However, through our company's efforts, we improved cooling performance and gas venting, resulting in a reduction in post-processing. Our company has many years of experience and advanced technology in the field of deep hole machining and gun drilling. Utilizing advanced gun drilling technology that enables precise deep hole machining, we provide high-quality processing services tailored to our customers' needs. 【Case Overview】 ■ Industry: Molds (Injection Molding, Aluminum Extrusion) ■ Component Information: DAC material, φ2.1×227.1mm, concentricity 0.04mm, inner diameter ±0.01 to 0.02 ■ Challenges: High risk of breakage due to ultra-fine diameter / Difficulty in ensuring straightness due to deep holes ■ Value Provided: Zero breakage with penetration / Achieved concentricity of 0.04mm / High reproducibility in long holes ■ Technical Points: Carbide drill, step feed, hydraulic control, straightness correction *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This service provides multifunctional machining that combines deep hole processing using gun drilling with internal shape processing such as tip SR, stepped structures, and through holes. It accommodates a wide range of diameters from φ0.5 to φ30, and has established a processing system that can consistently ensure straightness and coaxiality even for long workpieces with an L/D ratio exceeding 100. Depending on the application, machining methods can be selected, including tip SR for forming a uniform curved surface on the bottom of blind holes, stepped structures for changing diameters along the length, and through holes processed from both ends. By managing everything from outer diameter machining to internal shape finishing and inspection in a consistent manner, we provide stable quality that meets drawing requirements. 【Features】 ■ Broad support for tip SR, stepped structures, and through holes ■ Capable of deep hole processing from φ0.5 to φ30 ■ Supports long workpieces with an L/D ratio exceeding 100 ■ Ensures shape reproducibility through regrinding of dedicated tools *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "mold" is essential for the manufacturing of die-cast products. The steel used for that mold is called "die-cast mold steel." In this article, we will explain die-cast mold steel in an easy-to-understand manner for beginners. Die-cast mold steel requires four characteristics to produce stable quality products in harsh environments. *For more detailed information, please refer to the related links. Feel free to contact us for more details.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Isn't it true that there isn't a day in our daily lives when we don't see stainless steel products? For example, stainless steel is deeply embedded in our lives, from kitchen sinks and knives to building exteriors and even medical devices. You might be surprised to learn that the JIS standard name for stainless steel is referred to as "SUS materials." In this article, we will delve into the unknown charms and possibilities of SUS materials, exploring everything from basic knowledge to specialized processing techniques. *For more details, you can view the related links. Please feel free to contact us for more information.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

S45C steel is a type of carbon steel for machine structures specified by the Japanese JIS standards. It is known as a highly versatile material used in a wide range of applications, including machine parts and tools. This article will provide a detailed explanation of the characteristics and uses of S45C steel. *For more detailed information, please refer to the related links. Feel free to contact us for further inquiries.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Stainless steel is widely used in various industries due to its corrosion resistance and versatility. However, there are many variations of stainless steel, each with different characteristics and applications. This article will provide a detailed explanation of the basics of stainless steel, as well as the specific characteristics and application fields of each type. *For more detailed information, please refer to the related links. Feel free to contact us for further inquiries.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Copper has played an important role in human history for a long time. Its unique properties have enabled its use in many industries, and it is still considered an essential metal in modern society. This article provides a detailed explanation of copper's basic properties, its mining techniques, and how it is utilized in various industries. Additionally, it discusses the importance of copper's sustainability and recycling, as well as prospects for how future technological innovations may impact copper usage. *For detailed content of the article, please refer to the related links. For more information, feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Aluminum is a material known for its lightweight and high corrosion resistance, and it is widely used in many industries. This article will begin with the basic physical and chemical properties of aluminum, and will analyze in detail how technological innovations contribute to the evolution of aluminum materials, as well as how the use of aluminum is expected to develop in the future through specific application examples in the modern industrial world. We will focus on sustainable prospects for the future of aluminum and explore its potential. *For more detailed content of the article, please refer to the related links. For further inquiries, feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Resin processing technology plays an important role in modern industrial products. Recent technological innovations have significantly advanced the properties and processing methods of resin materials, expanding their applications across various industrial sectors. This article will provide an overview of the current state and evolution of resin processing technology, introduce new technologies, and conduct a detailed analysis of application fields. *For more detailed information, please refer to the related links. Feel free to contact us for further inquiries.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Stainless steel is a type of special steel characterized by its corrosion resistance (resistance to rust). One of the representative grades among them is SUS304. In this article, we will explain the basic properties, applications, and workability of SUS304 in an easy-to-understand manner, incorporating graphical elements. SUS304 is a type of austenitic stainless steel defined by Japanese Industrial Standards (JIS), and it is sometimes referred to as "18-8 stainless" because its main components are 18% chromium and 8% nickel. *For detailed content of the article, you can view it through the related links. For more information, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the medical field, materials such as SUS (stainless steel) are essential to meet the high demands for safety and precision in medical devices, surgical instruments, and implants. While it excels in corrosion resistance and biocompatibility, its low thermal conductivity and work hardening characteristics require advanced technology and process management for deep hole machining. Here, we will provide a detailed explanation of the technical challenges and countermeasures in deep hole machining of SUS materials, as well as specific application examples in the medical field. *For more detailed information, please refer to the related links. Feel free to contact us for further inquiries.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We provide high-precision deep hole machining daily, even for workpieces that have already undergone profiling, without any changes to the process on the customer's side. We have absolute confidence in the machining accuracy achieved through our in-house manufactured gun drill machines and processing technology, enabling us to perform high-precision deep hole machining on a wide variety of workpiece shapes. If you require deep hole contract machining, please feel free to contact us. 【Features】 ■ We have absolute confidence in the machining accuracy achieved through our in-house manufactured gun drill machines and processing technology. ■ We can perform high-precision deep hole machining on a wide variety of workpiece shapes. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company has over 1,000 types of drill diameters and drill lengths. With a top-class inventory of gun drills in the industry, we are always prepared with suitable machines, tools, and jigs to provide high-precision and high-quality deep hole machining to meet customer demands in a short delivery time. In particular, we have a wide range of small diameters (φ0.5 to φ6.0) available in 0.1mm increments, as well as many tool lengths. 【Features】 ■ Small diameters (φ0.5 to φ6.0) available in 0.1mm increments, with a wide selection of tool lengths ■ Custom jigs made in-house to accommodate special requirements ■ Ability to prepare and select suitable machines, tools, and jigs *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company also accommodates ultra-small diameter deep hole machining from Φ0.5 and above. By integrating the development of gun drill machines with deep hole machining technology, we have achieved ultra-small diameter deep hole machining in this field, such as hole diameter φ1.0mm with a depth of 400mm and hole diameter φ0.5mm with a depth of 60mm, using gun drilling. Please feel free to contact us when you need our services. 【Features】 ■ Supports ultra-small diameter deep hole machining from Φ0.5 ■ Capable of achieving high surface roughness in deep hole machining *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

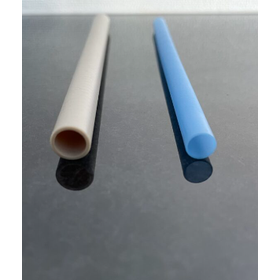

We would like to introduce our "deep hole processing for resin." We can drill holes over 200 times deeper in one go, significantly reducing work time and providing a much more profitable processing method compared to other methods, without the need to change a large number of tools. Even when drilling holes several meters deep, the surface roughness remains below 3.2S, allowing for precise finishing. 【Features】 ■ Excellent surface roughness due to the vanishing effect of the gun drill ■ Good concentricity (can also accommodate thin-walled processing) ■ Processing time is faster compared to other cutting methods ■ Good hole diameter accuracy *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "Deep Hole Machining for Aerospace (Difficult-to-Cut Materials)." Our Gundrill machines are designed with advanced technology to meet the complex demands specific to aerospace components, featuring high-quality spindle motors that ensure reliable and stable operation. Additionally, they are equipped with ideal conditions for the aerospace industry, such as suitability for long and deep hole machining, stable machining speeds, and minimal heat generation. [Features] - Main materials: Inconel, Hastelloy - Usable for high-frequency hardened materials - Fuel injection systems (difficult-to-cut materials) - Temperature sensor protection tubes (extremely thin wall machining) - Jet aircraft gear shafts *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "deep hole machining for automotive parts." This is a cost-effective production method used to create numerous holes in parts such as transmission shafts, engine blocks, airbag chambers, camshafts, and other internal engine components. Deep hole machining using gun drilling is a crucial material removal process in industries such as automotive, mold making, and turbines, and it is expected to become more complex with increasing demand in the future. 【Features】 ■ Used to create numerous holes in parts ■ Cost-effective production method *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce our "small-diameter deep hole machining for medical devices." Our Gundrill machine is specially designed to handle high-difficulty machining applications and medical and dental components. We provide excellent precision and outstanding surface finish even for difficult-to-machine materials such as titanium and medical stainless steel. [Features] - Main materials: β-titanium, nickel-titanium, etc. - Capable of drilling holes in workpieces that have been machined to shape. *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In addition to gun drilling machines, we have various processing machines such as honing machines, machining centers, wire electrical discharge machines, micro machining centers, cylindrical grinding machines, and multiple types of CNC lathes. As a result, we can provide consistent support from material shaping to deep hole processing, offering a variety of high-precision machined products.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Deep hole machining, which is a processing know-how of HI-TAK, has gained popularity since its introduction. Considering the high precision and outstanding performance this technology offers, it is only natural that it becomes an increasingly attractive option for operators in various industries and applications. HI-TAK's gun drill machines are currently one of the most comprehensive deep hole machining technologies, equipped with technical advantages that can accommodate a variety of applications. Our uniquely developed hollow spindle motor and proprietary international patent technology, along with years of contract machining experience, allow us to achieve optimal results for each machining process, ensuring the highest precision and productivity. We achieve top-level precision in deep hole machining, enabling cost-effective production through the use of high-tech materials.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This catalog introduces the machines handled by Hi-Tack Co., Ltd. We have a wide lineup including a small-diameter gundrill machine with a relative rotation type at φ1.0mm and L/D=400, as well as various gundrill machines tailored to workpiece shapes. Please make use of this for selecting products. 【Featured Products】 ■ Relative rotation type small-diameter gundrill machine "JDH-600-RF/JDH-600-R" ■ Table type small-diameter gundrill machine "JDH-600-TF/JDH-600-T" ■ Relative rotation type gundrill machine "JDH-300-R" ■ Simple table type small-diameter gundrill machine "JDH-400-STS/JDH-400-ST" *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our Gundrill Machine / Deep Hole Machining Machine meets a wide variety of needs in fields such as medical, aerospace, automotive, and semiconductors. In particular, it can achieve high coaxiality (concentricity) deep hole machining with a gundrill (tool) for extremely small diameters (φ0.5 gundrill) and workpieces with an L/D (depth to diameter ratio) exceeding 200, which were difficult to handle with conventional small diameter gundrill machines / small diameter deep hole machining machines. In addition to overseas sales models, we offer a wide range of conventional domestic sales models, allowing us to propose the most suitable machine for our customers.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company has the technology to perform high-precision deep hole machining on workpieces that have already been shaped, and we have established a system to carry out not only deep hole machining but also external cutting processes. We possess a wide variety of machines, including various CNC lathes, machining centers, wire electrical discharge machines, micro machining centers, cylindrical grinding machines, and work cleaning equipment. As a result, we can provide consistent support from material shaping to deep hole machining for both inner and outer diameters, allowing us to meet various cutting processing requests from our customers. Additionally, since we can manufacture jigs in-house with a short cycle time, we can respond to prototype development requests more flexibly and with shorter lead times.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We have developed a technology that enables honing processing of unprecedented small diameters and long lengths. Currently, our company is utilizing the technology cultivated through the development of gun drilling machines to create honing machines and honing tools that achieve extremely small diameters and processing lengths beyond existing capabilities. The target performance allows for honing of inner diameters from 1.0 to 10.0 mm and depths of 1,200 mm, making it possible to hone not only through holes but also blind holes, eccentric holes, and square bars. The development of this machine will enable improvements in the inner surface roughness of medical surgical tools and materials, as well as fine adjustments of deep hole inner diameter tolerances, all at lower costs than before, making it applicable in a wide range of fields.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company has developed a gun drill machine equipped with a built-in servo spindle that enables high rotational accuracy, providing "gun drilling deep hole processing" to meet various customer needs. So far, we have worked with over 50 companies in the medical field alone. We have successfully handled extremely challenging processes, such as workpieces that have undergone external processing and requirements for concentricity of Φ0.05. 【Features】 ■ Capable of processing small quantities (1 piece) ■ High-precision processing can help reduce material costs ■ Collaboration with partner factories allows for large-diameter deep hole processing and external diameter processing ■ Engaged in research and development of high-precision deep hole processing (processing technology, design and manufacturing of gun drill machines) *For more details, please download the PDF or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration