1~45 item / All 516 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry Form1~45 item / All 516 items

This is an example of cushioning material made for ring cases using die-cut processing. By using sponge processing tailored to the ring placement position, a stable holding structure is achieved as an internal pad for the case. In jewelry cases and ring cases, it is important to design cushioning materials that conform to the shape of the stored items. Through die-cut processing using sponge material, it is possible to consistently reproduce the slit shape of the ring insertion area and the external dimensions.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer cut products in the shape of a hedgehog using ECS color foam. We can create sponge products in shapes tailored to specific applications and designs. ECS is lightweight and easy to handle, and as a color foam, it is also utilized for miscellaneous goods and novelty purposes. In the case of cut products in animal shapes like this one, we reproduce the shape while considering the contours and fine details.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We support the production of cushioning materials and internal pads for cases using ECS black sponge. It is possible to cut shapes according to the application, such as card key holders and storage compartments for small parts. ECS black is a lightweight and easy-to-handle sponge material that is easy to use as interior material for cases. Due to its calm black color, it blends well with display cases and equipment storage cases, resulting in a pleasing finish.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

High sheet PP press and punching (die cutting) processing with method changes as needed. We support press processing and punching (die cutting) using high sheet PP (polypropylene). We process flat sheets into shapes and hole patterns, finishing them as components suited for various applications. High sheet PP is a lightweight and easy-to-handle material that combines ease of bending with appropriate rigidity. It is used in a wide range of applications, including insulation, partition plates, and cover components. Depending on the quantity and shape conditions, we may suggest changes to cutting processes in addition to punching, considering efficiency and finish.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We provide comprehensive support from the production of laminated products using sponge and rubber materials to adhesive processing and assembly processes. Not only can we handle single-item processing, but we can also manufacture composite products that combine multiple components. In laminated processing, by combining materials of varying thicknesses and hardness, we can achieve cushioning and retention properties tailored to specific applications. In adhesive processing, we use double-sided tape and adhesives to create a stable integrated structure.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We support the production of internal pads for cases with a laminated step structure using A-8 special black sponge. By combining sponges of different thicknesses, it is possible to create an interior configuration with steps that matches the height and shape of the stored items. The laminated step structure makes it easy to separate the contact points for each stored item, allowing for stable holding and fitting. A-8 special black has a calm color tone and moderate elasticity, making it a user-friendly material for the interior of display and transport cases.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer band cutting processing for rubber sheets. This process involves cutting sheet rubber materials into strips according to specified widths, and it is used in a wide range of applications such as padding materials, spacers, and cushioning purposes. The rubber materials we can accommodate can be selected based on the intended use and environmental conditions, and we can handle thicknesses of approximately up to 10mm. We can also discuss options for thicknesses exceeding 10mm.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We support the production of punched products using Sanpelca L-1400. Sanpelca L-1400 has a good balance of resilience and shape stability, making it a material often used for case interiors and cushioning applications. In punching processes, areas that are prone to stress due to their shape, such as corners and thin sections, can affect the final result. Depending on the application, by specifying delicate areas in advance, we can provide a response that takes into account the shape and processing conditions.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We support the production of punched products using Sanpelca L-1400. Sanpelca L-1400 has a good balance of resilience and shape stability, making it a material often used for case interiors and cushioning applications. In punching processes, areas that are prone to stress due to their shape, such as corners and thin sections, can affect the final result. Depending on the application, by specifying delicate areas in advance, we can provide a response that takes into account the shape and processing conditions.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It corresponds to cushioning materials with circular hole processing using B-4 sponge. For fragile products such as plates and ceramic items, it is a cushioning structure that can hold the shape during transportation. By applying circular hole processing, the outer circumference of the product is supported on a surface, making it easier to reduce shifting and impacts during movement. The B-4 sponge has moderate elasticity, which helps soften impacts on the ceramic surface while providing stable holding. 【Processing Points】 - Production of cushioning materials using B-4 sponge - Shape retention through circular hole processing - Dimension adjustments to fit plates and ceramic sizes - Hole arrangements designed for multiple placements are also possible - Impact adjustments considering transportation use

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We support the processing of small cut products with a thickness of 10t using ECS sponge. ECS is a lightweight and easy-to-handle sponge material used for various applications as cushioning and padding. In the case of small shapes, dimensional stability and finish are important, so we differentiate between punching and cutting processes according to the shape and quantity. We can process from simple shapes to partially punched shapes, tailored to the application. 【Processing Points】 - Processing support for 10t ECS sponge - Stable shape reproduction for small sizes - Mass production support through punching - Flexible shape adaptation through cutting - Selection of processing methods according to quantity and specifications

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We support the production of cut products using urethane foam. This case involves a simple rectangular shape processed from urethane foam with a thickness of 10t, and due to the large quantity, we have adopted die-cutting processing. In the case of simple shapes and mass production, using die-cutting allows for efficient processing while ensuring shape stability. For smaller quantities, we will produce cut products. It is easier to control variations in external dimensions, making it suitable for components that are used repeatedly. It is used as the bottom plate of pads inside cases.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer the production of cushioning materials for card holders using ECS sponge. The sponge shape is adjusted to fit the interior of cases or holders that store cards, resulting in an interior configuration that considers impact during insertion and removal as well as retention. ECS sponge is characterized by being lightweight and easy to handle, with a texture that is less likely to scratch the surface of cards. By combining partition shapes and groove shapes, it is possible to create a cushioning structure that can stably store multiple cards.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

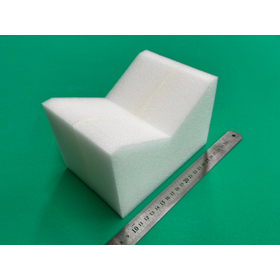

We support the production of assembled and three-dimensional shapes using sponge material. Not only can we perform flat cutting, but by combining bonding and layering, we can create three-dimensional sponge products tailored to specific applications. Sponge is lightweight and highly workable, making it easy to create structures that conform to the shape of the items being stored, as well as retaining structures that wrap around them. It is suitable for applications that require three-dimensional configurations, such as interior cases and display materials. 【Features of Sponge Assembly and Three-Dimensional Processing】 - Support for three-dimensional shapes using combined sponge materials - Shape configuration through layering and bonding - Lightweight and easy-to-handle structure - Customizable impact adjustments according to application - Capable of handling shapes that are difficult with flat processing

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Rubber Washer Cover Urethane Rubber 2t Punching Process We support punching processes for rubber washer and cover shapes using 2t urethane rubber. Urethane rubber excels in elasticity and wear resistance, making it a widely used material for cushioning parts and vibration mitigation, as well as for cover applications. In a washer + cover structure like this, the balance of outer diameter, inner diameter, and thickness is crucial, and it is necessary to optimize dimensions according to the usage environment and assembly conditions. Through the punching process, we can ensure stable dimensions and edge shapes, accommodating both mass production and small lots. Depending on the thickness, there may be cases where production is done using other processing methods such as machining instead of punching.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We support the punching processing of rubber washers made from urethane rubber. Urethane rubber with a thickness of 2mm offers a good balance of elasticity and resilience, making it an easy-to-use material for applications such as impact adjustment and vibration mitigation. In the shape of rubber washers, the dimensional balance of the outer and inner diameters, as well as the finishing of the edge, affects the user experience. We adjust the processing conditions according to the application and quantity, ensuring a stable shape in the final product.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We support circular sponge punching processing with an outer diameter of 59φ and a thickness of 5t. The sponge material has cushioning properties and is easy to use for various applications such as cushioning materials and padding. Circular punching processing is a method where the stability of the outer diameter dimensions and the finishing of the edges can significantly affect the user experience. For the 5t thick sponge, we adjust the processing conditions according to the application and quantity, ensuring a stable shape in the final product.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer processed rubber gaskets for water drain valve applications. This case involves a processed example of a deformed gasket shape with a thickness of 2mm, an outer diameter of 40mm, and an inner diameter of 27.5mm. Gaskets for water drain valves are components where sealing performance and dimensional balance are crucial, requiring gasket shapes that match the configuration and fastening conditions of the installation site. Even in the case of deformed shapes, we can accommodate outer and inner diameter processing according to the application.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer processing that involves slitting existing rubber tubes. Rubber tubes can be difficult to install or further process in their original state, but by adding slits, it becomes easier to cover and assemble them, thereby expanding their applications for wire protection and component fixation. Slitting is performed while considering the outer diameter, inner diameter, and material of the tube, and the depth and position of the cuts are adjusted according to the intended use. Since soft rubber materials are prone to deformation, we take care to maintain shape and ensure the stability of the cut edges during processing.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PP high sheet (blue 150T, 1.5t) is compatible with punching processing. The lightweight and easy-to-handle PP sheet is a material used for a wide range of applications, including partition materials, protective materials, and simple parts. PP high sheet (especially high sheet PP grade) is a hygienic packing material primarily based on low-foaming polyethylene resin, laminated on both sides with OPP (oriented polypropylene) film to enhance gas barrier properties. It has low odor, low water absorption, and moderate cushioning properties, making it ideal for cap packing for beverages and pharmaceuticals. The 1.5t thin PP is prone to warping and escaping during punching, so the alignment of the die and pressure balance significantly affect the finishing accuracy. Processing conditions are adjusted according to the application to achieve a stable shape.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer punched products in gasket shapes made from NEO-180 material. This is a general-purpose rubber primarily made from chloroprene (CR), which has been improved for oil resistance and cold resistance through a formulated blend, suitable for use in various fields. This time, we present a processing example with a thickness of 1.5t and an outer diameter of 80.5, featuring a hole-punched design. NEO-180 is a material that is easy to consider for sealing properties and resilience, making it a user-friendly material for gasket applications. Due to its thin nature, the processing details can significantly affect the outer diameter accuracy and hole position reproducibility in the finished product.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We support the production of corporate logos using sponge material. The lightweight and easy-to-handle sponge material is suitable for various applications such as exhibitions, events, and internal displays. We offer shape cutting and letter cutting processes tailored to the shape and size of your logo, providing logo designs that suit your needs. You can also consult us about configurations that take advantage of thickness, not just flat logos.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

As an original product of Fujika Industries, we have created a horse-shaped sponge. We have also been selling it at exhibitions such as local product fairs, and it has become very popular, especially among housewives and children. While it is, of course, suitable for dishwashing, it can also be used as a toy for children. We produce a sponge representing the zodiac every year, so we anticipate that next year will feature a sheep-shaped sponge.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We are capable of producing internal sponges for mannequins using B4 sponge (15t). The B4 sponge, which has moderate elasticity and cushioning properties, is easy to handle as an internal structural material and is suitable for shape retention and impact adjustment. We perform external cutting and partial cutting processes to match the internal structure and shape of the mannequin, finishing it into a sponge shape that fits easily inside. The 15t thickness is designed to minimize pressure on the internal space, making it easy to use for support and holding purposes.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We can accommodate the production of internal pads tailored to watch cases for display purposes. By using sponge material, we can create lightweight and easy-to-handle interiors that gently support the watch itself. We adjust the shape and contact points of the pads according to the size and shape of the watch, as well as the layout within the case. We also consider the visibility and angle of the watch face, proposing a configuration that enhances visibility during display.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We are capable of producing cylindrical shaped products using ECS sponge. The specification for this time is a cylindrical sponge with a length of 100mm. Cylindrical shapes are easily affected by the balance of outer diameter, inner diameter, and length, as well as the stability during cutting, making the adjustment of processing conditions important. In this case, we took measures in the mold design to ensure shape retention and processing stability. However, it still does not turn out perfectly straight and tends to have some waviness.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We can create case pads and cushioning materials tailored to existing cases. By using sponge materials, we can produce interior fittings that are lightweight, easy to handle, and gently protect the stored items. We adjust the size of the sponge pads according to the internal dimensions of the case and the shape of the equipment or parts to be stored, ensuring a perfect fit for the existing case. This specification is also easy to use for replacing the interior of commercially available cases or as an added cushioning material.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

By stacking cut A-8 sponge products, we can create logos with a three-dimensional feel. Utilizing the lightweight and processable nature of sponge material, it is possible to produce logo shapes that are easy to use for display logos and display purposes. By layering the cut A-8 sponge, we can achieve logo expressions with thickness and steps, providing visibility that differs from flat logos. The size and stacking configuration can be adjusted according to the intended use.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We support logo printing on sponge materials. By printing logos or text on sponge products, it is possible to enhance visibility and appeal for various applications such as interior case decoration, display materials, and novelties. The sponge materials used include urethane foam and expanded polyethylene, with the appropriate material selected according to the application. We carry out sponge printing while considering the softness and surface condition of the material. After printing, the cushioning properties are less likely to be compromised, resulting in a finish that retains the unique texture of the sponge.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an inner pad designed to fit the shape of the official Kamen Rider case. It fits existing cases and allows for customization of the contents inside. Since it is a made-to-order item, you can reflect your preferences, thereby enhancing its value as a collection. This service can also be repurposed for various items, including not only hobbies but also jewelry, precious metals, precision instruments, fragile items, and more.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We accommodate the production of internal pads and cushioning materials tailored to existing cases. By using sponge materials, we can create interior fittings that are lightweight, easy to handle, and gently protect the stored items. We adjust the size of the sponge pads to match the internal dimensions of the case and the shape of the equipment or parts being stored, ensuring a perfect fit for the existing case. This specification is also easy to use for replacing the interior of commercially available cases or as an added cushioning material.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We create logos for exhibitions and events entirely using sponge material. The lightweight and easy-to-handle sponge material makes setup and takedown simple, which is a key feature for exhibition use. We can achieve various shape expressions tailored to the design, including contour cuts and letter cutouts. We can also accommodate three-dimensional structures with added thickness and adjust the size to fit the exhibition space.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We create custom-made cushioning materials for hobby products and collectible items. It is possible to consider the interior configuration to match storage items of different shapes and sizes, such as figures and models. By using sponge materials, we can provide lightweight and easy-to-handle cushioning that is less likely to scratch surfaces. We also take into account stability during storage and ease of retrieval, focusing on configurations that emphasize a fit suitable for the intended use.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We support the production of internal pads for hobby cases. We will consider an interior configuration that fits stably within the case, tailored to the shape and size of collectibles such as figures and models. By using sponge material, we can create an interior that is lightweight, easy to handle, and resistant to surface scratches. We also take into account stability during storage and ease of access, designing a fit that is mindful of collection preservation. It is also possible to create prototypes using inexpensive sponge, and then use more expensive sponge material for the final product.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We propose custom processed products that are ideal for displays, promotions, and decorations. At Fujika Industries, we support the creation of corporate logos using sponge materials (foam). We can achieve "eye-catching logo expressions" in various scenes such as exhibitions, events, store decorations, and promotional items. Sponge materials are lightweight and easy to handle, and due to their high shape reproducibility, they are perfect for producing three-dimensional letters, symbol marks, and accent parts.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It is also ideal for the transportation and display of glass products, crafts, and tableware. At Fujika Industries, we design and manufacture inner cushioning materials using sponge materials such as polyethylene foam and urethane foam. When transporting "delicate and fragile items" such as glass products, ceramics, crafts, and handmade works, the selection and design of appropriate sponge materials are extremely important. We provide inner cushioning that can be safely transported by combining the optimal material with the optimal design, tailored to the shape, weight, and fragility of the items being stored.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We provide comprehensive support from material selection to packaging and delivery (Fujika Industries). At Fujika Industries Co., Ltd., we own three dedicated punching machines for processing, enabling us to perform high-precision punching on a wide variety of rubber, sponge, and resin materials. ■ Equipment Owned (Excerpt) Machine No. 1: 430 × 450mm (Thickness capacity up to 15t) Machine No. 3: 650 × 500mm (Thickness capacity up to 20t) Machine No. 5: 600 × 1200mm (Thickness capacity up to 100t) By utilizing these three machines with different sizes and thicknesses, we can accommodate a wide range of products, from small to large and from thin to thick. ■ We offer one-stop support At Fujika Industries, we do not just punch; we provide a one-stop service that includes material selection → drawing adjustments → tape application processing → inspection → packaging → delivery. We can flexibly respond to requests such as: "I want to consult about material selection." "I want to create a prototype to confirm the shape." "I want to stabilize the quality of mass production."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an example of a joint model (puzzle shape) made using B-200 (PE foam), where individual parts are produced through water jet processing and then assembled to complete the model. ■ Processing Details Material Name: B-200 (Polyethylene Foam) Processing Method: Water Jet Cutting Production Method: Processing individual parts one by one → Assembling to form the structure Applications: Joint components, puzzle-type structures, display models, component fixing pads ■ Features of B-200 High density with beautiful cut surfaces Stability that minimizes deformation even with combined parts Good fit of joints due to moderate hardness Stable dimensional accuracy despite being a foam Rigidity suitable for display, fixing, and three-dimensional structures ■ Advantages of Water Jet Processing No need for molds, can be produced from a single piece Edges remain intact, allowing for high-precision reproduction of intricate joint shapes No thermal impact, preserving the texture of the material This processing method is very suitable for products that require complex interlocking shapes like puzzles. If you are struggling with the selection of sponge materials or production methods, please feel free to contact us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a case where we consistently handled the design, production, and delivery of custom cushioning foam for tool storage using A-8 (polyethylene foam) with a thickness of 22mm from the planning stage. A-8 is lightweight and has a moderate hardness, making it a highly regarded material for storage inners that securely hold tools and precision parts while allowing for easy retrieval. ■ Processing Details Material Used: A-8 (black) 22mm thick Processing Method: Cutting plotter Scope of Work: - Storage layout design - Recess design tailored to tool shapes - Cutting processing - Adjustments for incorporation into cases - Consistent support until final delivery We performed recess processing based on the shape of the tools, resulting in a finish that balances "prevention of rattling" and "good visibility."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Fujika Industries also supports cutting and bonding through manual processing. We can handle not only our own products but also projects that involve bonding from other companies. 【Suggestions】 - Bonding of rubber tubes - Bonding of rubber gaskets - Cutting of gaskets and tubes

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Prototype】A-8 Base Creation / Model Production - Plotter Processing - Using expanded polyethylene A-8, we produced a base for the model with a plotter. Thanks to the cutting plotter processing, which allows for free-form cuts without the need for molds, this method is suitable for small lot prototypes and shape verification. A-8 combines moderate hardness and lightweight properties, making it an easy-to-handle material for display bases and storage spacers. By performing contour processing tailored to the shape of the model, we achieved both stable placement and protection. There are still some aspects regarding precision that are uncertain, so we will continue to refine blade adjustments and machine support to manufacture items with higher accuracy.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

[Prototype] Santech Foam Q25 (60+60t) Plotter Processing Santech Foam is a cross-linked extruded foam primarily made from polyethylene, known for its lightweight, flexibility, cushioning properties, thermal insulation, and chemical resistance. There is also an anti-static type, which is used as packaging material for electronic devices. In this instance, we have applied plotter cutting and double-sided tape to this material, creating a prototype with complex shapes that can be used as jigs or supports. By utilizing plotter processing, we can achieve short lead times and accommodate complex shapes. We also recommend using it as a supporting material for display items such as trophies. Fujika Industry not only handles industrial products but also accepts orders for fixtures and display items. If you have any concerns, please feel free to consult with us. Depending on your needs, we can also restructure the content for: - More technical emphasis - Sales-oriented text - Website publication If you have any issues, please do not hesitate to contact us!!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company also engages in design production as part of internal events and team activities. We planned and designed original T-shirts for internal events using external tools. Please feel free to use this as an option to enhance your events!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Trial Production】 Plotter Cut Yupo Paper Half Cut Crease Line Production ■ Processing Details Material Name: Yupo Paper (Synthetic Paper) Processing Method: Half cut and crease line processing using a cutting plotter Purpose: To confirm the half cut suitability of Yupo paper and the reproducibility of crease lines (bending processing) ■ Processing Results The half cut was consistently achievable, and by adjusting the cutting depth, it was processed precisely without penetrating the back side. For the crease lines, a shallow cut at a consistent depth resulted in an easy-to-fold finish. However, it is recognized that if the cutting pressure is too strong, the surface may crack slightly (whitening phenomenon), so caution is needed with the setting values. Both the half cut and crease line sections exhibited good dimensional and positional accuracy.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■ Processing Details Material Name: Silicone Rubber Thickness: 1t Processing Method: Circular cut test using a cutting plotter Processing Dimensions: Sequentially reducing the outer diameter from 15φ in 0.5mm increments (e.g., 15φ → 14.5φ → 14φ …) Purpose: To verify the accuracy of fine circular cuts and the blade tip followability in thin silicone materials.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration