1~23 item / All 23 items

Displayed results

Filter by category

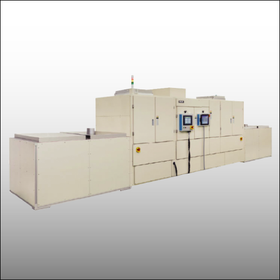

Semiconductor-related products

This is an introduction to semiconductor-related products.