See Image Processing's detailed category ranking

Visualizing chocolate stops occurring on the manufacturing floor! Network-compatible and compact.

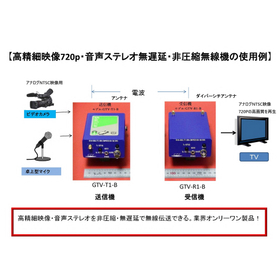

The definitive version of a Japanese-made wireless device for video and audio transmission! A long-selling high-quality wireless device with 100% no delay, also capable of battery operation. Experience it with a demo unit!

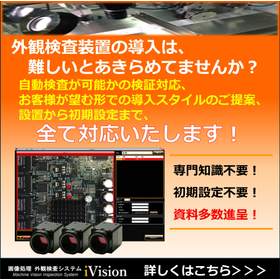

I want to automate visual inspections, but I'm worried whether it can accommodate my company's products. 'iVision' will support you all the way to implementation. [Case study available]

To all trading company sales representatives, is it difficult to propose the image processing appearance inspection system, and are you missing out on business opportunities?

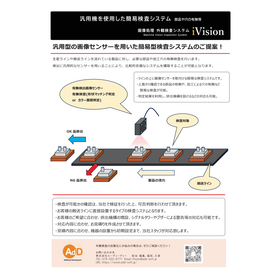

Would you like to automate simple visual inspections by installing a general-purpose image sensor on the conveyor line?

Production Technology, Inspection Line, Quality Control: Automation of Appearance Inspection with No-Code AI Enables In-House Development

Are you considering automating the inspection of distortions and shrinkage in transparent glass, resin, and films? Here's good news for those who think it's difficult without visual inspection!

You can inspect the side and bottom of cylindrical tubular components or containers! There is no need to rotate multiple cameras or workpieces to inspect the sides and bottom!

[Attention Power Utility Operators!] Constant monitoring of suspicious boats and intruders around facilities! Real-time enhancement of images that are difficult to see during bad weather such as fog, haze, rain, and snow.

For products that are difficult to laser engrave or tag! Individual identification of various items without processing or tags! Contributes to ensuring traceability and reducing management workload.