Chuck's technical information is consolidated! A web showroom for machine tool products has been launched.

Easily search for what you want to know! Technical information about zippers is available. *Videos are currently available.

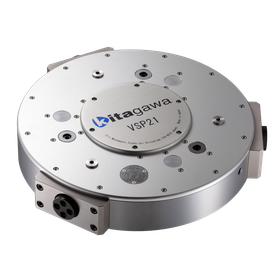

Kitagawa Iron Works has launched a web showroom called "Kitagawa WEB SHOWROOM," which consolidates technical information about machine tools. Here, we provide technical information about our products, accept inquiries from customers, and showcase new and featured products to enhance customer convenience. Currently, we have published technical information on chucks. We will continue to add content regarding technical information in the future, so please stay tuned. We sincerely look forward to your visit. ★Visit the web showroom here★ https://prod.kiw.co.jp/exhibition/mtools/ 【Contents Included】 ■ Soft Jaw Search ■ Hard Jaw Search and Gripping Range ■ Scroll Chuck Jaw Search ■ Parts List Search ■ Main Unit Addition - Working Range Diagram ■ Power Chuck Composition ■ Power Chuck Operation Mechanism and Classification ■ Gripping Examples ■ Usage Precautions ■ Information on Grease ■ How to Set Gripping Force ■ How to Attach to the Machine ■ How to Remove from the Machine ■ Disassembly and Assembly Methods ■ Failures and Countermeasures *For more details, please feel free to contact us.

- Company:北川鉄工所

- Price:Other

![Vacuum chuck (made of honeycomb panel) [ultra-fine hole type φ0.03mm]](https://image.mono.ipros.com/public/product/image/597/2000114113/IPROS7865307634577457303.jpg?w=280&h=280)