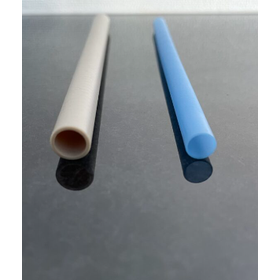

[Processing Example] Plate Material Fine Hole Processing

Contributing to cost reduction! Introducing examples of fine hole processing with "Warabiyama Carbon."

"Warashiyama Carbon" is our machining technology that supports various cutting processes, from continuous micro-hole machining to outer and inner diameter processing of round bars, and is capable of handling everything from prototypes and small quantities to mass production due to its flexible machining capabilities. It is possible to continuously process over 100 micro-holes with a diameter of φ0.5mm to φ0.2mm using a single cutting tool. Additionally, we have successfully reduced costs by using our uniquely developed cutting tools. Furthermore, we can process both UD and cross materials with a thickness of 0.5mm to 1.5mm. [Processing Examples] ■ Micro-hole machining (φ0.5mm) ■ Micro-hole machining (φ0.3mm・φ0.2mm) ■ Continuous micro-hole machining (φ0.3mm・φ0.2mm) *For more details, please refer to the PDF document or feel free to contact us.

- Company:共和製作所 本社

- Price:Other

![[Processing Example] Plate Material Fine Hole Processing](https://image.mono.ipros.com/public/product/image/c93/2000355615/IPROS8406461974096968925.jpg?w=280&h=280)