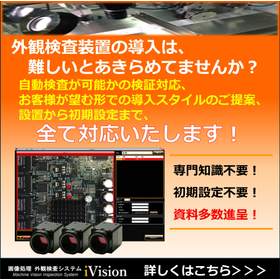

Image Processing Appearance Inspection System iVision (Regarding Metal Inspection)

If you are engaged in metal processing such as casting, forging, pressing, cutting, and grinding, and are considering automatic inspection of your products, why not consider iVision?

Even when we talk about metal processing, there are various manufacturing methods such as casting, forging, die casting, and pressing, and in terms of processing, there are also various finishing methods like cutting, plating, and mirror finishing, resulting in a wide variety of finished states. However, regardless of the type of products being made, inspections are always necessary. For aspects that cannot be discerned visually, such as weight and conductivity, various measuring devices are likely used, but many still rely on visual inspections for appearance checks. Some may be considering automating inspections, but they might be unsure about how to proceed or whether their products can truly be inspected. For those individuals, how about trying our "iVision"? We confirm with our customers what they want to inspect and under what conditions, and we conduct preliminary validations to ensure that it can indeed be verified. Additionally, we have a wealth of experience in verification and implementation for numerous metal products, including those related to the automotive industry. If you think, "Our products are too difficult, so it's impossible," or "We were turned down by other companies," we encourage you to give it a try.

- Company:エーディーディー

- Price:Other