The subcontractor has gone out of business. Consolidating rubber material mixing and molding to improve quality and reduce burden!

The procurement of rubber materials is complex from Company A, and finished products are sourced from Company B. Production transfer due to business closure. By consolidating rubber material mixing and molding, we achieve quality improvement and reduced burden!

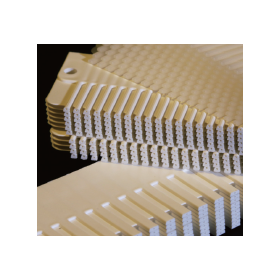

■Specific Concerns "I want to transfer production because the rubber molding manufacturer I had been using has gone out of business." "I'm also handling the procurement of rubber materials, and honestly, it's quite difficult to manage." ■Solution Our company provides a comprehensive service from rubber material mixing to molding and delivery. We align quality levels during the transfer and refine the processes. ■Effects The production transfer resolves the risk of disruption in the supply chain. The comprehensive service from rubber material mixing to delivery significantly reduces procurement management efforts. By refining the processes, both quality and delivery times have greatly improved compared to before the transfer. ■Customer Feedback "I was really helped by being able to successfully transfer production when I was in trouble due to the sudden closure of my subcontractor." "Since they provide a comprehensive service for rubber materials as well, my management has really improved, and they maintain quality and delivery compliance, which is great." *For more details, please download the materials or feel free to contact us.*

- Company:信栄ゴム工業

- Price:Other