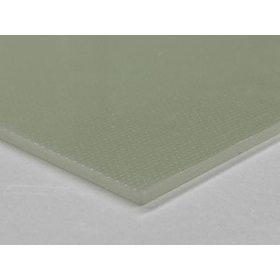

Nicolite® NL-EG (equivalent to EL-GEM, Nikko Chemical)

Standard grade glass epoxy laminate (equivalent to EL-GEM, equivalent to G-10)

In general, epoxy resins have good insulation properties, moisture resistance, dimensional stability, chemical resistance, and adhesion, and they are particularly excellent in alkali resistance. Products with glass cloth substrates include standard types (G-10), flame-retardant types (FR-4), and heat-resistant types (G-11), all of which excel in mechanical strength, electrical properties, low water absorption, and chemical resistance. This case introduces Nikolite® NL-EG manufactured by Nikko Chemical Co., Ltd. It is a standard epoxy glass insulating material, equivalent to the JIS standard EL-GEM, and corresponds to general products (G-10). Applications include "terminal boards, insulating washers, heavy electrical equipment, and communication devices." Meisei Electric provides one-stop solutions from material selection and procurement of thermosetting resins, including glass epoxy, and engineering plastics, to various processing such as cutting, molding, polishing, bending, and adhesion. If you have any questions or inquiries, please feel free to consult with us.

- Company:明星電気 本社(世田谷区用賀)、東北営業所(郡山市)、中部営業所(春日井市)、白河工場(西白河郡泉崎村)

- Price:Other