Energy-saving and removal performance, without compromise. Air nozzle 'Hayate'.

Energy saving × High-performance removal = The true value of the air nozzle 'Hayate'

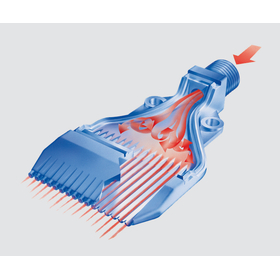

In recent years, while efforts for energy conservation have accelerated, there is a dilemma on-site where removal performance and work efficiency cannot be compromised. Therefore, we would like to propose the high-performance air nozzle 'Hayate' with laminar flow air blow. 1. A design that does not compromise on energy savings or performance Hayate significantly reduces air consumption compared to conventional nozzles through its unique flow path design, while achieving stable air blow with high wind speed and long distance. This ensures energy savings while enabling high-level removal of foreign substances and water droplets. 2. High-precision removal with laminar flow air The straight and uniform laminar flow air effectively reaches details that are difficult to access with normal turbulence. It can accurately remove fine objects such as water droplets on food containers and dust on electronic components. 3. Quiet design for improved work environment Hayate not only achieves energy savings but also features a low-noise structure. It can be used with confidence even in production lines where noise control is necessary. 5. Ideal for initiatives related to GX and CSR As part of carbon pricing and GX compliance, it supports not only energy savings but also improvements in work quality and the environment.

- Company:トリーエンジニアリング

- Price:Other

![[Free Rental Campaign] Experience success with Hayate by using it!](https://image.mono.ipros.com/public/product/image/34e/2001522574/IPROS5951300227439925519.png?w=280&h=280)

![[Semiconductor/Class 100 Compatible] 100% Water-Free Air Nozzle](https://image.mono.ipros.com/public/product/image/2116982/IPROS15202438644694791694.png?w=280&h=280)

![[Patent] Achieving an air nozzle that completely removes water with air blow.](https://image.mono.ipros.com/public/product/image/2116982/IPROS16998950562973190030.png?w=280&h=280)

![[Water Droplet Removal Video] PET Bottle (Cap) Edition](https://image.mono.ipros.com/public/product/image/f81/2001483074/IPROS3398708920822938976.jpg?w=280&h=280)