Machinable ceramic products

Machinable ceramics have relatively good machinability, making them suitable for complex shapes, fine details, and high-precision machining, as well as enabling quick delivery.

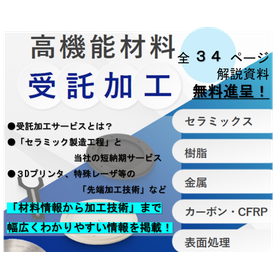

Machinable ceramics can be machined multiple times like general resins and metals, as they are not fired after cutting. However, they are harder and more brittle compared to general resins and metals, making them more prone to chipping, which results in poorer machinability and longer processing times. Our company sells ceramic processed products and processes ceramic materials supplied by customers (processing is generally outsourced). Based on the drawings provided by customers, we handle material selection, material procurement, machining, and firing, supplying parts and components for heat resistance, wear resistance, corrosion resistance, electrical insulation, and more to customers across various industries. We can also process ceramic materials supplied by customers. The features are as follows: - We handle a wide range of ceramics, allowing us to supply most materials. - Using various machines such as machining centers, NC lathes, and grinders, we can produce most shapes. - We can accommodate a wide range of production quantities, from one piece to ten thousand pieces. - We understand the characteristics of various ceramics and can select the optimal materials according to requirements.

- Company:ユタカ産業 本社・工場

- Price:Other