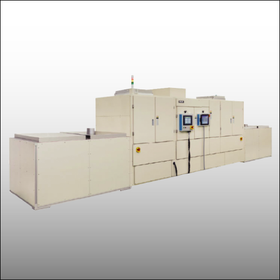

It is a hybrid deposition device that allows for the deposition of organic materials and metal materials in the same chamber. Co-evaporation of organic and metal materials is possible.

Eight organic deposition cells (KOD-Cell) for organic material film formation are available, and during metal material deposition, a metal deposition cell is standardly equipped in the same room. Both the organic and metal systems are configured with small-sized crucibles, focusing on minimizing chamber contamination within the device chamber. Additionally, it is a system that can be connected to a glove box. This system is a hybrid deposition device that allows for film formation of organic materials and metal materials in the same room.

Inquire About This Product

basic information

**Features** - Organic and metal materials can be deposited in the same chamber. - Co-evaporation of organic and metal materials is possible. - Co-evaporation of organic materials is possible (up to 4 components). - Standard water-cooled jacket to prevent contamination between organic and metal materials. - Substrates and masks can be exchanged in a vacuum environment within the deposition chamber. - The gap between the substrate and the mask is minimized. - The substrate rotation mechanism ensures film thickness uniformity within ±5% across the surface. - The organic deposition cell has excellent directionality and minimal material contamination in the deposition chamber. - Each processing chamber is treated with a special surface treatment for rapid attainment of the operating vacuum pressure. - It can be connected to a glove box. - Automatic transport and exhaust are possible with PLC control. - The introduction chamber can stock up to 5 substrate and mask holders as standard. - Equipped with a substrate heating chamber for pretreatment.

Price information

-

Delivery Time

Applications/Examples of results

【Applications】 - Development of organic EL materials - Development of polymer materials - Development of phosphorescent materials - Development of organic thin-film solar cells - Development of organic electronic devices, etc.

catalog(2)

Download All CatalogsCompany information

The history of Kitano Seiki is also a trajectory of continuous contribution to cutting-edge research fields through the provision of precision instruments for research and development. In November 1958, we were established as a company specializing in the design, manufacturing, and sales of precision instruments. Since then, we have developed and manufactured experimental equipment aimed at research institutes in universities and government agencies, as well as basic research laboratories in private companies, earning high praise for our excellent quality and reliability. In particular, in recent years, we have been at the forefront of ultra-high vacuum and ultra-low temperature technologies, which are essential in industrial fields such as new materials, nanotechnology, flat panel displays, high-temperature superconductivity, solar cells, nuclear power, and space development. We have accumulated abundant technology and know-how in creating experimental environments and have linked this to the development and provision of equipment that condenses advanced performance and functionality. At Kitano Seiki, we always work closely with researchers, our users, to design and develop equipment that accurately supports research and development objectives. With a consistent system from parts manufacturing to various processing, assembly, inspection and testing, equipment setup, and after-sales support, we provide high-quality products and a conducive experimental environment for quality research and development.

![[Comprehensive Catalog] Vacuum Equipment and Parts](https://image.mono.ipros.com/public/catalog/image/01/f50/46217/IPROS7012029363570825385.png?w=120&h=170)