See Contract Services's detailed category ranking

A comprehensive catalog of high-performance chemicals essential for the manufacturing of electrical and electronic devices, filled with 110 years of experience, technology, and know-how.

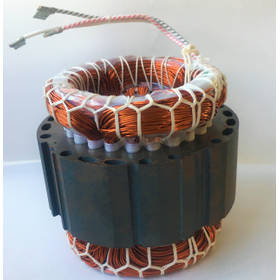

Solve the "challenges" of production technology from upstream concepts. Complete the automation of large, heavy, and diverse products.

As an expert in casting and forging processing, we can provide comprehensive support from arranging aluminum and iron castings to precision machining, quality assurance, and delivery of finished products.

[Case study available] Significant reduction in component costs through overseas production and process improvements! Specific examples of shortened lead times and enhanced quality are now publicly available.

A custom equipment manufacturer that can consult from the platform. We propose the best equipment for process improvement and automation challenges!

Leveraging the technological expertise cultivated in amusement equipment, we provide comprehensive support for product development. We offer one-stop solutions for bringing products to market, from prototyping to mass production phases.

We needed 20,000 lead processing units in four weeks, but there were no companies available to handle it, so this is a case where we received a request from our company.

For entrusted design and manufacturing of plastics and electrical/electronic equipment, please leave it to Takawa Electric Industry, known for its trust and proven track record.

Compatible with signs, posts, functional gate pillars, gates, handrails, canopies, objects, etc.!

Leveraging abundant experience and technical expertise to provide high-quality chemical products. Equipped with a variety of analytical instruments, we also ensure thorough quality control.

Improving machining accuracy of machining centers through numerical correction contributes to solving issues in the manufacturing site, such as "uniformity of processing quality" and "reduction of startup time."

The electronic gun is a telefocus type made by pro-beam! Please feel free to consult us when you need it.

Support from product planning to filling, processing, and shipping for additives, cleaning agents, chemicals, deodorizing and disinfecting agents, etc.! For those who have raw materials but no place to fill them.

Far superior in corrosion resistance and plasma resistance compared to protective films created by thermal spraying or aerosol deposition! Yttrium oxide produced by a unique ion-assisted deposition method.