Tamagawa Engineering Co., Ltd.

A technology partner that expands the possibilities of manufacturing, from induction heating to automation.

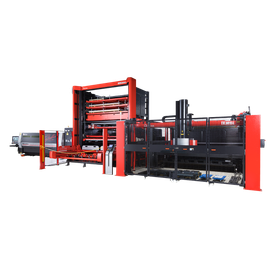

Creating user-friendly machines - Equipment manufacturing (Mechanical and Electrical) We respond to customer requests in various fields, including the design, manufacturing, installation, and maintenance of automation and labor-saving machines, as well as various industrial machines from vacuum to high pressure, and addressing pollution and environmental issues. Maintenance At Tamagawa Engineering, we engage in improvements and enhancements to increase the maintainability, reliability, and safety of equipment. We focus on maintaining and improving machine performance, preventing failures, and extending lifespan, all aimed at enhancing quality and operational rates while reducing maintenance costs. With our accumulated wide-ranging know-how and experience, we provide total services to carry out equipment maintenance more efficiently with our exceptional technical capabilities.

- Company:NPO諏訪圏ものづくり推進機構

- Price:Other

![[New Product] Complete parts insertion and screw tightening in one machine! Introducing the JM-E01.](https://image.mono.ipros.com/public/product/image/77f/2001463977/IPROS62841365498851631582.jpeg?w=280&h=280)