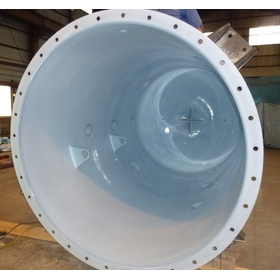

Fluororesin sheet lining processing for duct lining of flue gas desulfurization equipment.

Achieving strong adhesion! By using a special adhesive, we have improved high-temperature performance.

By applying fluororesin sheet lining to ducts (smoke ducts) used in smoke exhaust desulfurization devices and electrostatic precipitators, we improve non-stick properties, corrosion resistance, and durability. This extends the lifespan, allows for significant cost reductions, and makes maintenance after installation easy. Our company boasts a wealth of delivery experience as a developer of the fluororesin sheet lining method (with international patent). Please feel free to contact us when needed. 【Features】 ■ Achieves strong adhesion by laminating glass cloth to the adhesive layer ■ Improves high-temperature performance by using special adhesives ■ Extends lifespan and allows for significant cost reductions ■ Makes maintenance after installation easy *For more details, please refer to the PDF materials or feel free to contact us.

- Company:ニッシンコーポレーション 本社

- Price:Other

![Basic Knowledge of Fluororesin Sheet Lining [Technical Document]](https://image.mono.ipros.com/public/product/image/48e/2000735447/IPROS99196862127070271167.png?w=280&h=280)

![[Business Introduction] Pipe Lining Division](https://image.mono.ipros.com/public/product/image/747/2000333653/IPROS4576650009773528118.png?w=280&h=280)

![[Information] Chemical Resistance of Rubber Lining](https://image.mono.ipros.com/public/product/image/279/2000820746/IPROS48782464280480763675.png?w=280&h=280)