Overcoming with Honing & Cutting Processing! Countermeasures for Mold Loss Troubles

Lost the mold? No delivery date? In such cases, breakthrough with honing and machining.

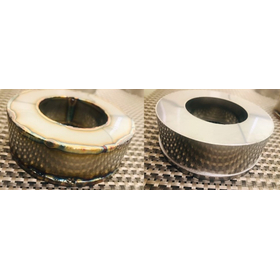

"Could you please do it as soon as possible, somehow?" Among the drawings that arrived, there was a particularly eye-catching part. The material was FCD450—meaning cast iron. The quantity was small, just 30 pieces, but the shape was complex, and the drawing date was ten years ago. Feeling a slight unease, I confirmed with the customer, and as expected— "Actually, the current processing company has lost the mold..." Normally, it would be unavoidable to have a long lead time to remake the mold. However, the drawing specified **±0.005 dimensional tolerance and Ra0.2 surface roughness**, and furthermore, that area was the "cylinder sliding part." In other words, it was a high-precision part that required honing. At Bandai, we replaced everything with cutting without using a mold, and by collaborating with a honing-specialized processing partner, we achieved the shortest possible lead time. Even without a mold, and even with strict precision— Our **"Hometown Processing Network" at Bandai** can respond to those "troubles." *Please note that this kind of response is just a small part of what Bandai does every day. We invite you to see the value we can provide to our customers.*

- Company:萬代 本社

- Price:Other

![[JIS] Quality designation symbols for copper and copper alloys](https://image.mono.ipros.com/public/product/image/155/2001194858/IPROS29808078146808331711.png?w=280&h=280)