To ensure equipment maintenance and the reliability and lifespan of electronic devices, it is effective to investigate corrosive substances in the operating environment and take countermeasures.

The usage environment of electronic devices varies. The impact of corrosion caused by various environmental factors tends to increase. Corrosive substances generated from hot springs, volcanoes, waste, and rivers can lead to corrosion of electronic components, printed circuit board wiring, connector contacts, and switch contacts in electrical equipment, potentially causing serious troubles.

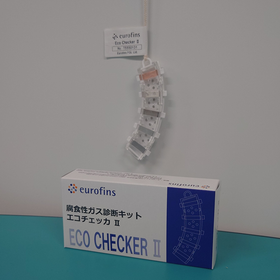

Therefore, investigating corrosive substances in the usage environment is effective for equipment maintenance and ensuring the reliability and lifespan of electronic devices. Our original corrosion environment diagnostic kit, "Eco Checker II," offers a low-cost and simple diagnostic procedure. It allows for easy investigations such as screening for corrosive substances through multi-point surveys.

■ Free Webinar Announcement! ■

We will introduce methods for diagnosing corrosion environments centered around our original corrosion environment diagnostic kit, Eco Checker II.

【Date】 July 22, 2025, 10:00–10:30

【Venue】 Online (Teams)

This is recommended for those who are concerned that atmospheric conditions in the operating environment may lead to electronic device failures, or who wish to reduce failure risks in harsh environments such as hot springs or wastewater treatment plants. If you wish to participate, please contact us!