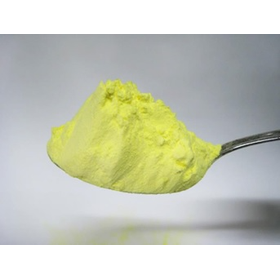

Spherical phenolic resin [Good fluidity and high filling capacity] *Characteristic table available.

By controlling the porosity, we can accommodate particle size control from 5 to 750 μm! We will meet your needs from particle size control to small lots.

The oldest resin, "phenolic resin," has been sphericalized! Particle size control is possible in the range of 5μm to 750μm! Being spherical, it has good fluidity, and there are uncured types that are reactive, thermosetting types that do not melt, and semi-cured types that fall in between. 【Features】 ○ Spherical shape with good fluidity, allowing for high filling. ○ High fixed carbon content, enabling the production of spherical carbides through firing and heat treatment. ○ High purity with no ash content. ○ The molded products possess heat resistance, mechanical strength, chemical resistance, and electrical insulation comparable to conventional phenolic resins. For more details, please contact us or download the catalog.

- Company:リグナイト

- Price:Other

![Spherical phenolic resin [Good fluidity and high filling capacity] *Characteristic table available.](https://image.mono.ipros.com/public/product/image/62b/2000310086/IPROS8375492184728129058.jpg?w=280&h=280)