We will respond to your prototype requests with cutting-edge laser microfabrication technology, providing high-quality processing that includes three-dimensional shapes.

Hikari Corporation is a joint venture with Germany's 3D-Micromac, a world-class manufacturer of laser microprocessing equipment, and acts as the general agent in Japan. We have introduced 3D-Micromac's picosecond laser microprocessing equipment within Hikari Corporation. With this cutting-edge laser microprocessing equipment, we will respond to your prototype requests. We achieve high-quality processing for hole drilling, cutting, and marking, regardless of the material being processed.

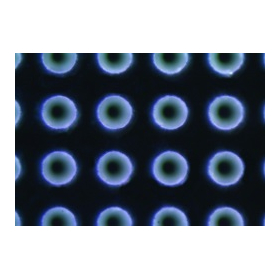

【Application Examples】

■ Metals: Micro hole processing, fine groove processing, thin film removal, marking, fine engraving, fine cutting

■ Ceramics, Glass, etc.: Fine engraving, fine cutting, marking, micro hole processing, laser lift-off

■ Resins: Micro hole processing, fine cutting, fine groove processing, coating removal

For more details, please contact us or refer to our catalog.

![[Prototype Acceptance in Progress] Examples of Laser Microfabrication Applications](https://image.mono.ipros.com/public/product/image/e60/2000156206/IPROS6108904142426905709.jpg?w=280&h=280)