1~31 item / All 31 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~31 item / All 31 items

Traditionally, gPROMS was only available with the necessary licenses, but it has now been packaged and can be used for a wide range of applications. It can be utilized for many considerations.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In plant design, equipment sizing, process consideration, and operational optimization, PSE believes that existing process simulators still have room for improvement in terms of convergence for obtaining numerical solutions, constraints of processes they can handle, and customization of process models (model extensibility). The process simulation software developed to meet the needs for more advanced and value-added process plant design and optimization is 'gPROMS Process'. 【Features】 * Libraries for specific applications * Creation of flow sheets using Drag & Drop * High-precision custom model creation and editing functions using gPROMS language * Changes in settings within the same environment from steady-state simulation models to dynamic simulation models * Powerful optimization solution search and analysis functions * Global System Analysis (GSA) * High-Performance Computing (HPC) ★ You can view two "case study materials" available for download. These include examples of achieving high-value product offerings and cost reduction through batch process optimization, as well as successful cases of cost reduction through the optimization of entire plants.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a modeling tool developed in collaboration with a U.S. mega-pharma company. Recently, the pharmaceutical industry has been transitioning from batch to continuous production, and it is being used for process design and control system considerations. It is a model library of gPROMS FormulatedProducts. In continuous production processes, advanced quality management (PAT, QbD, RTRT) and the ability to accommodate small-batch, diverse production become possible, but at the same time, high-precision process modeling technology becomes essential. If you want to "reduce plant construction costs," "increase production volume at existing plants," or "improve product quality (particle size distribution)," please feel free to contact us! You can watch the video on YouTube: https://youtu.be/AJZcgI-r2Ik

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

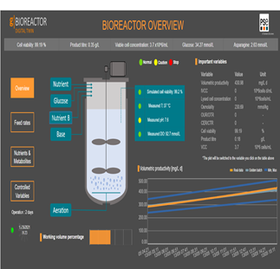

In the future, in the expanding bio market, why not challenge yourself to improve productivity using the power of software while keeping your existing equipment as is? What products can be created by maximizing the functionality of existing equipment? While satisfying your curiosity about particle size, production volume, and more, we contribute to "reducing development time and costs." By visualizing phenomena that were previously invisible through numbers and graphs, you can deepen your understanding of bioprocesses. <Effects> * Reduction in the number of experiments with the latest modeling features * Shortening of development time through early determination of design space (with validation features) * Risk management during continuous production and scale-up * Optimization of batch crystallization recipes * Monitoring of product quality through digital twins Siemens PSE's bio-related library models (also possible to create digital twins) ■ Bioreactor ■ Fermentation tank ■ Chromatography ■ Filtration ■ Freeze-drying * For more details, please download the PDF, and feel free to reach out if you have any questions.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Nova Advanced Cell Science Seminar 2022 [Future Biopharmaceutical Manufacturing] This is a presentation video from the event hosted by Nova Biomedical (September 2022). YouTube video (approximately 16 minutes) Monitoring the operation status of bioreactors with digital twins - Towards building QbD... https://www.youtube.com/watch?v=7JvVQeR7B-I

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

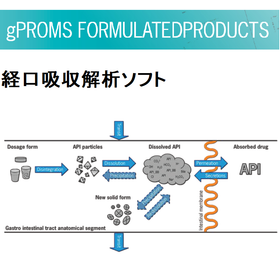

gPROMS Formulated Products is a modeling tool for solid and powder processes. In cases applied to pharmaceutical processes, it enables consistent performance analysis of the entire system, from active pharmaceutical ingredient (API) manufacturing through formulation processes to risk analysis of oral absorption. Our software has already been implemented by major pharmaceutical companies in Europe, the United States, and Japan. We will send you three simulation materials related to API manufacturing, crystallization, formulation, and oral absorption (Technical Information Association, separate print) by mail (free of charge). 1. Optimal design of API manufacturing and formulation processes using modeling tools 2. Optimization of crystallization processes using simulation and modeling tools 3. Correlation between process parameters and quality characteristics using AI We hope this will be useful as part of further efficiency improvements in "continuous production" and new drug development. If you are interested, please contact us by writing "Request for Process Modeling Materials" in the "Inquiry" section.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The term "DX (Digital Transformation)" has become frequently seen in the internet and books, but do you think of "DX = IT implementation"? DX is not just about the introduction of technology; it requires a reevaluation of management policies, business models, and even the organizational structure itself. Therefore, it is important to promote DX that is suitable for your company with a "bird's eye view," rather than a stopgap approach. Our company handles 'gOES', which digitizes processes in chemical manufacturing, pharmaceutical manufacturing, and food manufacturing, allowing for simulations. Based on data measured by sensors connected to products and factory equipment, we create a "digital twin" that enables customers to grasp the health and performance of their production processes in real-time. This contributes to efforts aimed at optimizing operating conditions. ■ Companies that don't know what they should do with DX. ■ Companies considering the digitalization of manufacturing processes. ■ Companies that want to understand and improve the state of their production processes should definitely take a look! *For more details, please refer to the materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In order to build a decarbonized society, our company offers the following solutions: 1. CO2 Capture and Utilization One of the initiatives to reduce emissions is "CCUS." "CCUS" stands for "Carbon dioxide Capture, Utilization and Storage," which aims to utilize separated and stored CO2. 【gCCS】 A system modeling tool for the design and operational support of the CCS chain, developed in collaboration with E.ON (a German energy company supplying electricity and gas), EDF (a French electric utility company), Rolls-Royce Motor Cars (a British automobile manufacturer), and CO2DeepStore, funded by a project from the UK government agency (ETI). 2. Hydrogen Process Technology 3. gPROMS Utilities: Daily CO2 Emission Reduction Operational Support Optimization Tool

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Self-study materials for gPROMS Formulated Products are available, including crystallization, bioprocessing, continuous direct compression, drying granulation, spray drying, tablet manufacturing, oral absorption, and more. For details, please check the following website. https://assets.new.siemens.com/siemens/assets/api/uuid:4ccd210d-31cb-418c-afac-8cd32d93977f/gPROMS-FormulatedProducts-self-paced-resources-catalog.pdf

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"Digital Transformation (DX)" has become mainstream, and more companies are establishing "DX departments." How about you? DX is not just about introducing technology; it requires a reevaluation of management policies, business models, and even organizational structures. Therefore, it is essential to promote a DX that suits your company rather than just a temporary fix. Our company offers 'gOES,' which digitizes processes in chemical manufacturing, pharmaceutical manufacturing, and food manufacturing, allowing for simulations. Based on data measured by sensors connected to products and factory equipment, we create a "digital twin" that enables customers to monitor the health and performance of their production processes in real-time. This contributes to efforts aimed at optimizing operating conditions. Among our lineup, 'gUTILITIES' is software for utility optimization. We have achieved energy cost reductions of 2-10% and a payback period of less than 9 months. *For more details, please refer to the materials or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

As part of the gPROMS Formulated Products library, there is an oral absorption analysis tool. In the analysis of oral absorption of pharmaceuticals, it is possible to quantitatively understand the effects of drug administration schedules, feeding conditions, and formulation on oral absorption. 【Features】 ■ Steady-state and dynamic (transient) simulation ■ Handling of multiple recycle streams ■ Optimization of plant design and operating methods ■ Identification and estimation of process equipment performance from test data ■ Graphical representation of batch plant operating procedures ■ Integration with crystallization process analysis library ■ Integration with oral absorption analysis library *For more details about the product, please visit our website.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The term "DX (Digital Transformation)" has become frequently seen in the internet and books, but do you have an image of it? DX is not just about the introduction of technology; it requires a reevaluation of management policies, business models, and even the organizational structure itself. Therefore, it is important to promote a DX that fits your company rather than just a stopgap solution. Our company offers 'gOES', which digitizes processes in chemical manufacturing, pharmaceutical manufacturing, and food manufacturing, allowing for simulations. Based on data measured by sensors connected to products and factory equipment, we create a "digital twin" that enables customers to grasp the health and performance of their production processes in real-time. This contributes to efforts aimed at optimizing operating conditions. Among our lineup, 'gOLEFINS' is software for accurate measurement prediction and monitoring of ethylene cracking furnaces. By focusing solely on ethylene yield, large-scale plants have achieved cost reductions of $1 million to $3 million per month. *For more details, please refer to the materials or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company offers 'gOES (gPROMS Operational Excellence Solutions)', which digitalizes processes such as chemical manufacturing, pharmaceutical manufacturing, and food production, allowing for simulations. Based on data measured by sensors connected to products, systems, and factory equipment, we construct a "digital twin" that enables real-time understanding of the health and performance of production processes. This contributes to efforts aimed at optimizing operating conditions and more. It is suitable for companies considering the digitalization of manufacturing processes and those looking to understand and improve the state of production processes that are not visible in reality. 【Features】 ■ Can be embedded in control systems (DCS) for online use (soft sensors, digital twins, etc.) ■ Easily create complex chemical reaction models (custom models) ■ Extensive model library and physical property database

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company offers 'gOES (gPROMS Operational Excellence Solutions)', which digitalizes processes such as chemical manufacturing, pharmaceutical manufacturing, and food production, allowing for simulations. Based on data measured by sensors connected to products and factory equipment, we construct a "digital twin" that enables customers to monitor the health and performance of their production processes in real-time. This contributes to efforts aimed at optimizing operating conditions and more. It is suitable for companies considering the digitalization of manufacturing processes and those looking to understand and improve the state of their production processes. 【Product Lineup】 ■gOLEFINS: Software for accurate measurement prediction and monitoring of ethylene cracking furnaces ■gUTILITIES: Software for utility optimization ■gOILFIELD: Operational optimization of crude oil production systems ■gREFINERY: Operational monitoring of oil refining plants ■gREACTOR: Catalyst reactor model *For more details, please refer to the materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company has affiliated laboratory facilities, and we offer an outsourcing service to collect data from actual experiments using the catalysts from the samples you provide. Based on the experimental data, it is also possible to commission PSE for parameter fitting of the reaction model. Using the validated model, we can consider the design of reactors and optimal operating methods.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a modeling tool developed in collaboration with a U.S. mega-pharma company. Recently, the pharmaceutical industry has been transitioning from batch production to continuous production, and it is being used for process design and control system considerations. It is a model library of gPROMS FormulatedProducts. In continuous production processes, advanced quality management (PAT, QbD, RTRT) becomes possible, as well as the ability to handle small-batch, multi-product production, but at the same time, high-precision process modeling technology becomes essential. If you have any inquiries such as "I want to reduce plant construction costs," "I want to increase production volume at existing plants," or "I want to improve product quality (particle size distribution)," please feel free to contact us! 【Features】 ■ Capable of steady-state and dynamic (dynamic) simulation ■ Easily handles multiple recycle streams ■ Allows for optimization considerations of plant design and operation methods ■ Can identify and estimate process equipment performance from test data ■ Provides graphical representation of batch plant operating procedures ■ Can be linked with crystallization process analysis libraries ■ Can be linked with oral absorption analysis libraries *For more details about the product, please download the PDF from the link below.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The spray dryer allows for the consideration of product quality variation control and equipment scale-up (enlargement) by simulating factors that influence particle size control, moisture content control, and particle shape during the manufacturing process. In modeling, the particle size distribution is calculated based on the Population Balance equation, and the drying process of the particles is also taken into account. Additionally, representing adhesion to the walls is an important requirement in the simulation. With the integration of Siemens' STAR-CCM+, it is possible to analyze the actual gas flow in detail, which can be used for considerations of scale-up and operational improvements. This is an optional feature of gPROMS FormulatedProducts. *For more details, please download the catalog or contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A new feature has been added to gPROMS ProcessBuilder: "Optimization of Low-Density Polyethylene (LDPE) Autoclave Reactors." 【Advanced Polymer Thermodynamics】 The SAFT equation of state represents molecules as chains of different functional groups, accurately modeling branching and capturing precise polymer characteristics across the entire molecular weight distribution (MWD). This approach is ideal for polymer modeling. 【Complete MWD Modeling】 Detailed kinetic modeling considers the fundamental polymerization reaction steps in chemically initiated free radical polymerization. This model uses a fixed pivot method to predict the time evolution of the entire molecular weight distribution (MWD). 【CFD-Linked Multi-Zone Approach】 Advanced process modeling provides a means to understand the impact of changes in operating conditions on the shape of the MWD. 【PSE Consulting Services】 Consulting services provided by a specialized team ensure the swift and high-quality execution of projects.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PSI Japan provides sales and technical consulting services for the simulation platform software "gPROMS." This catalog introduces the technology of the gPROMS process modeling tool. [Contents] ■ gPROMS Model Builder ■ Field-specific application software on the gPROMS platform ■ Hybrid simulation (coupled calculations with CFD) ■ Physical properties estimation package ■ Operator training simulator (OTS) *For more details, please refer to the catalog or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We sell academic licenses for educational and research institutions. The content is almost the same as for corporate licenses, but they are available at a more affordable price. There are licenses available for research (1 unit) and for education (1 class). ■ gPROMS Process Research/Education License ■ gPROMS Formulated Products Research/Education License

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At SPSE, we regularly conduct product demonstrations and practical training for our products. The participation fee is free, so please feel free to join us. You will have the opportunity to use the software! ■ Introduction to gPROMS Process Model-based process engineering (batch and continuous processes) Catalyst reactor, adsorption separation, and membrane separation model library ■ Custom Modeling ■ Bioprocess Models ■ gPROMS Formulated Products Crystallization Analysis ■ gPROMS Formulated Products Oral Absorption Analysis *Please note that registration may take some time. We recommend applying early.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

gPROMS Formulated Products is equipped with a library of process models for operations such as reactions, crystallization, wet and dry milling, spray drying, wet and dry granulation, blending, and tablet compression. In case studies applied to pharmaceutical processes, it enables consistent performance analysis of the entire system from active pharmaceutical ingredient (API) manufacturing through formulation processes to oral absorption risk analysis. ■ Solution crystallization analysis ■ Solid-liquid and solid-gas separation, classification, and granulation process analysis ■ Oral absorption analysis This product was developed with the cooperation of major pharmaceutical companies in Europe and the United States. By using mathematical models of raw materials, unit operations, and product performance, it allows for formulation design aimed at optimizing pharmaceuticals and their manufacturing. It enables faster screening of new formulation candidates against quality attributes, including in vivo performance and manufacturability.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Fixed bed catalytic reactors are used for the production of various chemical raw materials, and their applications are wide-ranging. AML:FBCR is characterized by being a basic tool for the automatic estimation of reaction parameters for catalyst pellets in laboratory experiments, which can be scaled up for pilot or actual equipment studies. It is used as a model library on the simulation platform gPROMS ProcessBuilder. Furthermore, it allows for the representation of various units, including reactors, as a single process on one flow sheet, enabling the optimization of the entire plant. By using parameters adjusted based on experimental data in a precise kinetic model expressed by multiple equations and chemical reaction equations, the fundamental idea is to accurately predict the behavior of actual equipment with high model accuracy. Additionally, parameter estimation is also possible in the actual equipment model, expanding its applications such as estimating catalyst degradation.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"gOLEFINS" is an online monitor that accurately estimates the operational state of the furnace by acquiring information such as the outlet temperature of the reaction tube in the cracking furnace using a highly reliable model. It allows for the understanding of increased pressure loss due to coke accumulation and decreased heat transfer rates, enabling operational adjustments based on highly accurate predictions. This optimization of the operational conditions and decoking cycles of the cracking furnace has led to real examples of annual revenue increases of tens of millions of dollars. [Benefits] ■ Optimization of decoking through accurate end-of-run predictions ■ Optimization of operational margins for each cracking furnace ■ Continuous updates to the cracking furnace model through dynamic optimization of the entire cracking furnace *For more details, please refer to the materials. Feel free to contact us with any inquiries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the plant, various utilities such as fuel, electricity, and steam are consumed, which fluctuate constantly through multiple routes. Process plants can produce their own steam and fuel, and in the case of electricity, they can also sell it externally. The energy unit of each utility varies hourly, and factors such as maintenance of major equipment lead to daily fluctuations, making the issues even more complex. gUTILITIES finds precise optimal solutions while considering the current utility demand, utility unit costs, and availability, allowing for the identification of appropriate operating conditions even for complex utility systems. Cutting-edge optimization algorithms can search for and present better economic utility plans compared to traditional tools. High-speed optimization solvers can explore more options in a shorter time, thereby improving the efficiency of the energy management team.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the plant, various utilities such as fuel, electricity, and steam are consumed through multiple routes, fluctuating constantly. In process plants, there may also be self-production of steam and fuel or selling electricity. The energy unit of each utility varies hourly, and factors such as maintenance of major equipment failures fluctuate daily, making the issues even more complex. gUTILITIES provides a strictly optimized solution while considering the current utility demand, utility unit costs, and availability, allowing for the determination of appropriate operating conditions even for complex utility systems. Cutting-edge optimization algorithms can search for and present better economic utility plans compared to traditional tools. <Features> - Major libraries including gas turbines, boilers, and steam turbines - Flow sheet creation via drag-and-drop - A powerful, fast, and robust framework for optimization - High-speed processing enabled by equation-based solvers - Preprocessing of raw data through data reconciliation - Real-time advice for operators - Utility planner and advisor screens are easy to read and customizable.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

gPROMS ModelBuilder is a simulation platform software for supporting research and development, as well as equipment and plant design, which includes: - Process simulation (steady-state, dynamic) - Model validation (model parameter estimation) - Exploration of optimal experimental methods (design of experiments) - Optimization of operating methods and designs (static, dynamic optimization) - Plant automation (advanced control design and tuning) - Operator training (training simulator) It can be used for a variety of development support, analysis, and optimization considerations. By defining constants, variables, and equations using gPROMS Language and providing input values, model calculations can easily converge using the Initialization Procedure technology developed by PSE. After the initial calculation, it is possible to quickly recalculate by providing the automatically saved initial values.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Please see the list of webinars (online seminars) from the link below. Additionally, you can move to the webinar archive using the button on the right side of the page, where you can watch many past videos. Upcoming webinars will require pre-registration, and you can view them on the day of the event, but they will also be added to the archive later.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A detailed explanation of the development and system simulation of secondary batteries based on "gPROMS." You can view a case study on lead-acid battery modeling. There is a library for lead-acid batteries. For lithium-ion batteries, we provide support through custom modeling. By combining 1D and 2D models for verification, it is possible to calculate more accurate data and comprehensively consider the physical and chemical phenomena occurring in each battery component. We can also address issues related to battery operation. <1D Model> Mass balance of components Electrolyte and solid phase potentials - Ohm's law and concentrated solution theory Charge conservation (electrical neutrality) Electric double layer at the electrode/electrolyte interface Changes in porosity and loss of electrode surface area Electrochemical reactions - Butler-Volmer equation Sub-models connected through boundary condition systems Battery capacity loss <2D Model> 2D profiles of current, potential, and component concentration Ion transport represented by a more advanced approach: Maxwell-Stefan-Plank diffusion

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

<gPROMS FormulatedProducts Crystallization Process Library> It can be used for various considerations and decision-making in production volume enhancement, operational improvement, and process optimization. To build efficient procedures (recipes) in the crystallization process, we will efficiently carry out operations in the following flow and achieve these within a short period (approximately 1 to 2 months). Modeling → Experiment → Model Verification (Parameter Estimation, Validation) → Process Optimization Consideration → Scale-Up Consideration The ability to automatically perform parameter estimation with the tool is a significant factor in reducing the consideration period. Additionally, since it is a kinetic model (expressing mechanisms in mathematical formulas), the number of parameters is kept to a necessary minimum. Furthermore, tools that automatically optimize cooling temperature reduction methods and patterns, the amount and timing of seed crystals, evaporation rates, and heating patterns are powerful, and scale-up may be conducted in conjunction with CFD (Computational Fluid Dynamics) simulations when necessary.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The software package "gFUELCELL," based on our general-purpose mathematical modeling CAE software "gPROMS," is specialized for performance analysis and design optimization of fuel cells. In response to the demands of more customers, we have enhanced the functionality of the model library and revamped the user interface from the conventional AML:FC (Advanced Model Library for Fuel Cells). ■ Capable of building cell models that reflect experimental data ■ Precise handling of condensate in PEMFC ■ Analysis of dynamic behavior and performance of fuel cell systems considering degradation analysis ■ Risk management ■ Reduction of development costs for fuel cell development ■ Shortening of development time

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration