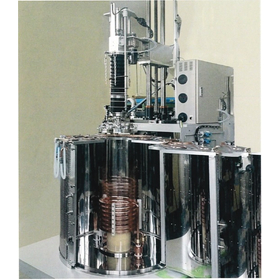

Uniform heating and stable heating under high vacuum or atmospheric pressure; drying, degassing, baking, annealing; multipurpose mass-production vacuum oven.

A versatile vacuum oven capable of large batch processing with dimensions of 800mm□×800mmH. It achieves high vacuum processing, inert atmospheric pressure treatment after vacuum replacement, low vacuum gas flow processing, and multiple processing modes all in one unit. Uniform heating under high vacuum for degassing and baking. Defoaming, degreasing, and vacuum drying in a low vacuum gas flow atmosphere. High-speed heating annealing of parts and molded products in an inert atmosphere after vacuum replacement. Customizable options available from a well-established standard type to meet individual needs. A lineup ranging from small sizes to suit various purposes.

Inquire About This Product

basic information

600mm□×600mmH / Large batch processing of batches Uniform heating with full heater inside the furnace Complete dry exhaust system with dry pump + turbo molecular pump Heating treatment compatible with high vacuum, low vacuum, and atmospheric pressure Exhaust system, gas system, processing temperature, furnace structure, and jig can be selected according to the substrate and purpose.

Price information

Please contact us.

Delivery Time

Applications/Examples of results

Drying and annealing of powders Degassing and annealing of small components Drying and firing of electronic device coatings Drying and annealing after painting resin molded products Drying of ceramic sheets

Line up(1)

| Model number | overview |

|---|---|

| Polyimide Cure Device | A cure device specifically for electronic devices that supports the curing of polyimide on 300mm semiconductor wafers. Uniform heating under low oxygen concentration after vacuum replacement. Proven performance and reliability in advanced semiconductor production lines. |

catalog(5)

Download All CatalogsCompany information

Shinko Seiki, as a technology-driven manufacturer, leverages the numerous know-how accumulated particularly in the field of vacuum equipment to deliver innovative products that meet user needs. In recent years, the company has also been challenging cutting-edge fields such as electronics and new materials, aiming to develop truly valuable hardware and software through the advancement of distinctive technologies and their organic integration.

![Vacuum Oven [Provides accurate and rapid heating and heat transfer] *Product catalog available](https://image.mono.ipros.com/public/product/image/c30/2001016716/IPROS78749435833515174488.png?w=280&h=280)

![Challenging Decarbonization Technologies! Introduction to the Thermal Technology Research Institute [Latest Information for 2025!]](https://image.mono.ipros.com/public/product/image/3d5/2000834196/IPROS99631596500298700026.jpeg?w=280&h=280)

![Venturi Mixer VM Series [2D/3D CAD]](https://image.mono.ipros.com/public/product/image/d2e/2000852305/IPROS58786938329892851049.png?w=280&h=280)