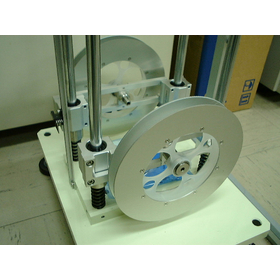

Agricultural Polyethylene and Agricultural Film Winding Machine 'CMS-1000/1400/2000'

A winding machine that demonstrates its effectiveness in collecting dirty vinyl sheets from soil disinfection work.

The "CMS-1000/1400/2000" is a sheet winding machine that makes it easy to collect and reuse vinyl sheets and poly sheets after soil disinfection work. You can choose from three winding lengths: 996mm (CMS-1000), 1,330mm (CMS-1400), and 1,990mm (CMS-2000). It is capable of winding up used sheets for tunnel cultivation, soil disinfection covering sheets, frost protection sheets, and discarded sheets, winding 100m of sheet in 4 to 5 minutes. 【Features】 ■ Demonstrates power in collecting dirty vinyl sheets during soil disinfection work ■ Can wind 100m of sheet in 4 to 5 minutes ■ Offers a lineup of three different products *For more details, please refer to the PDF document or feel free to contact us.

- Company:新興和産業

- Price:Other

![Products equipped with high safety and technical features [electronic-related machinery] *custom-made!](https://image.mono.ipros.com/public/product/image/699/2000294900/IPROS3113250811879027063.jpg?w=280&h=280)