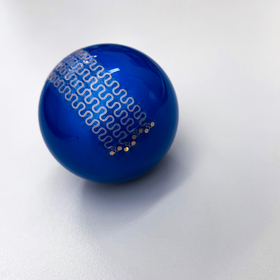

Flexible Printed Circuit (FPC) Catalog

A wide range of products including single-sided FPC, double-sided FPC, and flex-rigid are featured.

The "Flexible Printed Circuit (FPC) Catalog" is a catalog that widely introduces high-quality FPC products nurtured by Okiden Cable in a clean environment. The feature of Okiden Cable's Roll to Roll (RtoR) line is its ability to handle both single-sided and double-sided FPCs. All equipment is installed in a clean room with management considerations for dust prevention. [Contents] ■ Okiden Cable's FPC Product Concept ■ Areas of Achievement ■ Process Overview ■ What is a Flexible Printed Circuit (FPC)? ■ Product Introduction *For more details, please refer to the PDF document or feel free to contact us.

- Company:沖電線

- Price:Other

![[COMNEXT2024 Exhibition] FPC and Rigid FPC with ultra-short delivery times](https://image.mono.ipros.com/public/product/image/7e1/2001213763/IPROS41149340118484993302.jpeg?w=280&h=280)

![[Data Presentation] FPC Terminology Glossary, PDF search available. For use as an introductory mini-dictionary!](https://image.mono.ipros.com/public/product/image/791/2000888908/IPROS16631666073025694825.png?w=280&h=280)

![Types and Examples of High-Performance FPC [Special Bumps, Long and Ultra-Fine, High Flexibility]](https://image.mono.ipros.com/public/product/image/724/2000596102/IPROS82184144039263696681.png?w=280&h=280)

![[PCB Design and Product Design] FPC and Flexible Circuit Boards](https://image.mono.ipros.com/public/product/image/51a/2000509961/IPROS88069959853256374559.jpeg?w=280&h=280)