1~45 item / All 94 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry FormBefore making an inquiry

Download Profile1~45 item / All 94 items

Filter by category

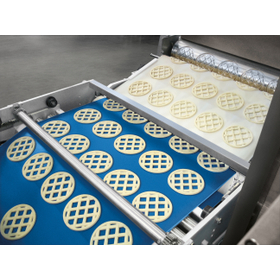

GEA Bakery offers a wide range of configurable machines for processing pies, tarts, quiches, and cheesecakes of various sizes and shapes on baking trays or embossed platens lined with aluminum foil, from compact machines to industrial-scale production lines.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the meat processing industry, consistent product quality and efficient productivity are important challenges. Particularly in the emulsification process involved in the production of sausages and pâtés, the proper mixing and uniformity of raw materials greatly influence the final product. Insufficient emulsification can lead to a deterioration in texture and variations in quality. The GEA CutMaster enables uniform cutting, mixing, and emulsification, and with heating/cooling options, it accommodates a variety of recipes. 【Usage Scenarios】 - Production of sausages, pâtés, meatballs, etc. - Emulsification process in meat processing - Adaptation to diverse recipes 【Benefits of Implementation】 - Achieving consistent product quality - Increased productivity - Adaptation to a variety of products

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the meat processing industry, various material shaping is required to meet diverse product needs. In particular, balancing production efficiency and product quality is crucial. Molding defects can lead to reduced yield and increased costs. The GEA MaxiFormer II accommodates a wide range of materials, including not only meat and seafood but also cheese, vegetables, and alternative meat products, achieving high efficiency, performance, consistency, sustainability, and controllability. 【Usage Scenarios】 - Shaping hamburgers, meatballs, sausages, etc., in meat processing plants - Shaping alternative meat products - Shaping seafood products 【Benefits of Implementation】 - Accommodates a wide variety of materials, expanding the product lineup - Balances high productivity and product quality - Extended operating time and increased productivity through continuous operation without the need for cleaning

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the chemical industry, it is essential to efficiently separate unwanted solids from reaction liquids to improve product quality and productivity. In particular, the removal of catalysts and by-products after the reaction significantly impacts subsequent processes, making rapid and reliable separation crucial. Improper separation can lead to a decline in product quality and equipment issues. Our small decanter-type solid-liquid separator DCD205 supports the production of high-quality products by separating fine solids in the sub-micron range, thanks to its high centrifugal force of up to 3400G and long rotating cylinder structure. 【Application Scenarios】 - Recovery of solids after reactions - Removal of by-products - Product purification 【Benefits of Implementation】 - Improved product quality - Increased production efficiency - Reduced running costs

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the livestock industry, proper treatment of sludge generated from the handling of livestock manure is required. In particular, controlling odors, reducing environmental impact, and efficient sludge reduction are important. Improper sludge treatment can lead to environmental pollution and conflicts with neighboring residents. Our decanter-type centrifuge dewatering machine is less prone to clogging and can operate with minimal wash water, contributing to the efficient treatment of livestock sludge. 【Usage Scenarios】 - Manure treatment in livestock farms - Sludge dewatering at livestock waste treatment facilities - Dewatering of digestate at biogas plants 【Benefits of Implementation】 - Reduction of sludge volume - Decrease in odors - Lower running costs - Reduced environmental impact

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an improved model of the GEA Denmark batch freeze dryer RAY series.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The GEA MaxiFormer II achieves high efficiency, performance, consistency, sustainability, and controllability. Drum molding allows for continuous operation without cleaning for up to 60 hours at 330 strokes per minute, significantly extending operating time and achieving industry-leading productivity.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

AromaPlus is a system based on reverse osmosis (RO) membranes, capable of handling processing volumes from small to large, and offers both batch and continuous options. AromaPlus can remove alcohol down to 0.5% or 0.05% ABV. (Consultation is required regarding product specifications before the de-alcoholization process.)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The new GEA Bake Extruder sets a new standard for high-speed industrial production, delivering exceptional flexibility for a wide range of bakery applications, with wirecut speeds of up to 350 strokes per minute. It combines unmatched performance, improved ease of use, and a hygienic design to enhance productivity and product quality. Whether used as a stand-alone machine or connected to an oven, this extruder is built to meet the demands of high-volume operations with precision and efficiency. GEA Bake Extruder offers versatility for multiple applications: Wirecut, Co-extruded, Filled Cookies, Continuous Extruded, and Like-Deposited products. With advanced features like the redesigned wirecut system, brushless motors, and customizable filler blocks, this extruder ensures high productivity while maintaining the highest product quality.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Nass blender utilizes the self-priming pump SIPLA, making it a device that allows for the speedy introduction of powders. It achieves cost reduction through "speed" and "efficiency." Designed with sanitation in mind, it contributes to improved work efficiency. *Testing (demo) is available at the GEA Sakura Service Center (Sakura City, Chiba Prefecture). 【Features】 ■ Inline processing of powder dissolution is possible ■ The self-priming sanitary pump SIPLA, with its powerful suction capability, draws in powders into the piping ■ Excellent sanitary design ■ Rapid dissolution of large quantities of powder ■ Easy operation with floor installation ■ Touch monitor can be added as an option Testing is available. If you are interested, please select "Request Demo" from "Contact Us via Web." For more details about the product, please view the materials from "Download Catalog."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The world's smallest single-use disk-type centrifuge, kytero10, has been released. This compact centrifuge is used in the development of products such as biopharmaceuticals. The kytero10 is the smallest model in GEA's cell separation equipment, accommodating processing volumes of approximately 1 to 10 liters. Its low shear design enables high cell viability in laboratory-scale continuous cell recovery and perfusion culture processes by utilizing centrifugal force. 【Features】 - Continuous production - No cross-contamination - No SIP/CIP required - Proven technology of GEA's disk-type centrifuges (uncompromising performance, scalability) *Please contact us for further information.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

【Features】 ■ Simple design prioritized for sanitation ■ Transfer of fluid within the hopper is possible by switching the three-way cock ■ Compact design allows for installation in narrow spaces

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The BisCat ceramic filter, which incorporates a catalytic matrix, enables the removal of fine particles, acidic gases, dioxins, mercury, VOCs, and NOx. The filter element is chemically inert and corrosion-resistant. Gas purification can be achieved in one step. The BisCat ceramic catalytic filter not only processes fine particles and acidic gases like traditional candle filters but also uses a catalyst that effectively removes NOx by injecting ammonia in advance, eliminating the need for conventional selective catalytic reduction (SCR) systems. To achieve advanced exhaust gas regulations, the BisCat filter integrates three processes into one unit: - Dust removal - Removal of acidic components - Reduction of unburned hydrocarbons (THC) and NOx The ceramic filter element can significantly reduce dust emissions (to < 2 mg/Nm3) and demonstrates heat resistance even at high temperatures. Since cooling of the exhaust gas is unnecessary, there is no waste of thermal energy during the introduction phase.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The GEA HYGiBulk system can accommodate low, medium, and high processing volumes for filling dry, flowable powders or granulated raw materials of food, dairy products, and nutritional supplements into flexible intermediate bulk containers (FIBC = flexitanks), bulk bags, and super sacks, even when it is necessary to handle pallets in packaging or filling areas within high-care zones.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

GEA has developed a "mobile" carbon capture pilot plant equipped with a gas pretreatment module as a proof of concept for target industries.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The GEA SmartFil M1 features customizable product weighing options, including a vertical auger and a horizontal vibrating feeder that can be selected based on the packaged product.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a decanter centrifuge from a major global manufacturer of centrifuges. Features of the decanter type: - No clogging - Minimal wash water - Closed type with low odor - Broadly adaptable to variations in sludge characteristics (concentration) - Automatic operation with minimal effort required - Small installation space

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a tunnel oven for bakery products handled by GEA Imaforni. Based on 100 years of experience in the bread and pastry sector, we offer a comprehensive range of industry-leading machinery used in production lines for cakes, pies, cookies, soft biscuits, hard biscuits, layer cakes, pastries, pizzas, crackers, snacks, and bread. With GEA's technical expertise, we design various types of ovens, including: ◆ Gas direct-fire ovens ◆ Indirect cyclotherm ovens ◆ Indirect convection ovens ◆ Hybrid ovens ◆ Electric heating ovens ◆ Special ovens We can also provide ovens with effective widths of up to 2,000mm for biscuits, cookies, crackers, and snacks, and up to 4,000mm for cakes, pies, pastries, and pizzas. We configure continuous production lines tailored to the type of products, production capacity, and processing capabilities of our customers.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is the optimal dewatering machine for reducing sludge volume. - High dewatering: Achieved through a high centrifugal force of up to 3400G to 4060G. - Compact: The long rotating cylinder structure allows for a compact design (small installation area) with high separation capability. - Automatic control: Constantly maintains optimal operating conditions through automatic adjustment of differential speed via torque control. - Safety monitoring: Continuously monitors the machine with various sensors (vibration, temperature, rotation). - Easy operation: Reduces operator workload with an automatic lubrication system for the main bearing, automatic control, safety monitoring, and ease of disassembly and assembly designed in Germany. - Comparison with other dewatering machines: The closed type produces less odor and prevents clogging, resulting in reduced cleaning water usage. It can also accommodate a wide range of variations in sludge characteristics.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a decanter centrifuge from a world-leading manufacturer of centrifuges. In biogas generation plants, our decanter is adopted more frequently than screw presses. - High dewatering: Achieved by a maximum centrifugal force of 3860G. - Compact: The long rotating cylinder structure allows for a compact design (small installation area) with high separation capability. - Automatic control: Automatic adjustment of differential speed through torque control maintains optimal operating conditions at all times. - Safety monitoring: Continuous monitoring of the machine using various sensors (vibration, temperature, rotation). - Easy operation: Features such as an automatic lubrication system for the main bearing, automatic control, safety monitoring, and ease of disassembly and assembly designed in Germany reduce the workload on operators. - Comparison with other dewatering machines: The closed type produces less odor and has no clogging, resulting in less cleaning water needed. It can also accommodate a wide range of variations in sludge properties. It has a higher recovery rate than press types and can recover fine solids as well. (This ultimately affects the moisture content.) It can operate without chemical injection.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an introduction to a case study of a major global manufacturer of centrifuges in Europe. In Europe, our decanters are more widely adopted than screw presses and decanters from other companies.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Introducing European examples that are leading in closed-loop land-based aquaculture (Recycling Aquaculture System). The solid matter removed by the filter is further reduced in volume. No chemicals (coagulants) are used, and the materials are compatible with salinity levels equivalent to seawater. High concentrations of sludge are separated without the use of drugs. Sludge is converted into fertilizer. The amount of sludge generated is calculated based on production volume (amount of feed), and equipment selection is made accordingly.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a decanter centrifuge from a world-leading manufacturer of centrifuges. It is ideal for dewatering, concentrating, and classifying solid materials. - High dewatering: Achieved by a high centrifugal force of up to 3400G. - High separation capability: The distinctive long rotating cylinder structure allows for the separation of difficult-to-settle solids, including sub-micron order small particles. - Compact: High separation capability with a small installation area. - Automatic control: Automatic adjustment of differential speed through torque control maintains optimal operating conditions at all times. - Safety monitoring: Continuous monitoring of the machine using various sensors (vibration, temperature, rotation). - Easy operation: Automatic lubrication system for the main bearing, automatic control, safety monitoring, and ease of disassembly and assembly designed in Germany reduce the operator's workload. - Table test available: Spin test with a small sample (100ml). - Actual machine test available: Conducted using a small test machine. - Solids dissolved in liquid cannot be separated.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is the optimal dewatering machine for reducing sludge volume. - High dewatering: Achieved by a maximum centrifugal force of 3400G. - Compact: Compact design (small installation area) with high separation capability due to the long rotating cylinder structure. - Automatic control: Constantly maintains optimal operating conditions through automatic adjustment of differential speed via torque control. - Safety monitoring: Continuously monitors the machine with various sensors (vibration, temperature, rotation). - Easy operation: Reduces operator burden with an automatic lubrication system for the main bearing, automatic control, safety monitoring, and ease of disassembly and assembly designed in Germany. - Comparison with other dewatering machines: The closed type produces less odor and has no clogging, resulting in reduced cleaning water. It can also accommodate a wide range of variations in sludge characteristics.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

GEA's vacuum cutter (bowl knife/bowl cutter/silent cutter) is a device suitable for the upstream processes of food processing, such as cutting, mixing, and emulsifying, and can also be used for alternative meat products and vegetarian products. It offers flexibility, allowing for quick adjustments to recipes such as knife and bowl rotation speeds and vacuum levels, resulting in high productivity. It can achieve uniform cutting and mixing of raw materials, from coarse chopping to fine emulsification. 【Features】 - Capable of uniform cutting, mixing, and emulsification in all processes - Optional cooking functions such as heating/cooling can be added - High hygienic design with excellent sanitation, preventing products or water from entering between the bowl and bowl cover - Reduces discharge time by using a multi-stage unloader - The exterior is sturdy and highly durable, with a small bowl volume that shortens vacuum time and facilitates easy cleaning - Control panel and vacuum pump are integrated for space-saving design

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

To significantly increase the recycling rate of plastic packaging, GEA has developed GEA FoodTray, an ecological cardboard/film composite solution. The cardboard and film are bonded together in the packaging machine, allowing consumers to easily separate them after use. Compared to previous packaging solutions, it reduces plastic usage by 80% and is fully recyclable. Additionally, it can be printed on the entire surface of the packaging, allowing for the depiction of products with text and images.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The highly efficient disc-type centrifuge technology, based on globally recognized GEA Westfalia's expertise in separation and decades of industrial-scale cell recovery solutions, is now available for the first time as a convenient click-operated production unit for product development in small-scale production and scalable labs. 【Features】 - Continuous production - No cross-contamination - No SIP/CIP required - Proven GEA disc-type centrifuge technology (uncompromising performance, scale-up) *Please contact us for further information and testing requests.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The GEA MultiFormer can shape a wide variety of materials, including red meat, pork, chicken, seafood, as well as cheese, vegetables, and alternative meat products. Additionally, the forming plates can be easily exchanged, enabling quick product changes.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer a clarifier that reflects the latest technology from GEA Westfalia Separator Group GmbH. 【Features】 - By improving the sludge discharge method, we reduce the discharge volume during raw milk clarification, minimizing raw milk loss. During CIP, complete discharge is achieved, maintaining high cleanliness. - By changing from traditional gear drive to belt drive, we significantly reduced the number of parts, enhancing maintainability. - We have also succeeded in reducing power consumption due to the switch to belt drive (15% compared to our previous model). - Raw milk processing capacity: Minimum 3,000 L/H, Maximum 15,000 L/H.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PAVAN, the largest company in the pasta industry under GEA, has over 70 years of experience in handling fresh pasta production lines. We will help you select the most efficient line and machinery from a variety of equipment suitable for different types such as gnocchi, ravioli, and lasagna. We offer machines for filling with various fillings, including sheet forming and meat (also accommodating liquid cheese), as well as cooking machines using water and steam, low-temperature sterilizers using steam, and cooling devices tailored to specific applications. Additionally, we have experience not only in the pasta sector but also in products like shumai and dumplings, so please feel free to contact us first.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This catalog features decanters used in the production of soy milk and cereal drinks handled by GEA. We introduce a hygienic decanter with unprecedented sanitary properties. Contents include: - Overview of the GEA Group - Decanter-type centrifugal separator

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Coolant fluids and cleaning solutions used in machine tools can become contaminated with oil, affecting product quality and the working environment. The OTC-type small centrifugal separator continuously separates and removes not only floating oil but also dispersed oil (emulsion oil) in the liquid due to strong centrifugal force. Effects: - Removes oil and solids from cleaning and cooling fluids, extending liquid life up to five times and reducing disposal costs. - Maintains low oil and solid concentrations, contributing to stable product quality. - Removes oil from the liquid, suppressing bacterial growth and ensuring a clean working environment.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

With the strengthening of SOx regulations, low-sulfur fuel oil is being adopted, while the risk of blockage in fuel oil systems due to abnormal sludge precipitation arises. Our oil purifier is equipped with moisture detectors and sludge detectors as standard. Even when there is a high amount of solids, it automatically discharges based on the amount of solid accumulation in the rotating body, regardless of the timer, thereby preventing the outflow of solids to the clean oil side and reducing the risk of blockage in the fuel oil system. 【Other Features】 - Fast sludge discharge speed and a rotating body that is resistant to dirt - Improved cleaning capability through high-temperature processing at 110°C - Selection based on certified flow rate (certified processing capacity by classification societies) is possible - Maintenance of the drive unit can be significantly reduced in time and cost by replacing complete units (OSF type: adopts direct drive method) 【Other Marine Products】 - Fuel supply adjustment device (booster unit) - Sludge separator - Bilge water separator - Scrubber water treatment device - Freshwater generator, etc.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We efficiently manufacture high-quality products and respond to various requests from single supply to unit supply. 【Features】 - Efficient oil-water separation using centrifugal force - CIP compatible - A lineup that can meet the demands of a wide range of industries, from traditional meal applications to food applications.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The clarification of hot wort, the clarification of young beer, turbidity adjustment, beer recovery, final beer filtration, etc., are optimal for the production of high-quality and efficient beer. We can accommodate various requests from single supply to unit supply. [Features] - Yeast crushing prevention mechanism - Oxygen pickup prevention mechanism - CIP compatible - Supports various scales from brewpubs to the world's largest breweries

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Ideal for the production of high-quality juices, purees, and smoothies. Easy installation and operation with a wheeled operating unit. Capable of handling from 1,000 l/h to 3,000 l/h. 【Features】 - Juice extraction technology under vacuum with patented technology - Strongly colored juice that does not brown - Quick extraction even in small quantities - High levels of vitamins, minerals, and polyphenols - Fresh aroma

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The GEA ColdSteam technology, which encapsulates low-temperature steam in a low-pressure environment, allows for hygienic thawing of frozen meat blocks in a shorter time compared to other thawing methods. After thawing, it can be directly tumbled or marinated. It achieves zero drip loss, meat quality similar to fresh meat, and reduced energy consumption. 【Features】 ■ Thawing time can be reduced by up to 75% ■ Eliminates loss of drip containing protein, improving yield and meat quality ■ High heat exchange rate achieved through a meticulously designed blade structure and brine pathway ■ Asymmetric blade shape allows for selection of hard and soft massage modes by changing the rotation direction ■ Large opening dimension of 900mm in diameter and an internal design without dead angles make discharge and cleaning easy ■ Multiple hygiene certifications obtained from public institutions in Europe and the United States ■ Over 20 years of experience with more than 300 units delivered worldwide ■ Maximum input capacity of 3500kg during thawing

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PAVAN, a leading manufacturer of pasta and snack production equipment with the world's top market share, has made it possible to produce corn flakes at lower running costs and raw material costs. Unlike traditional manufacturing methods, this is a cutting-edge production method using PAVAN's renowned twin-screw cooking extruder.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PAVAN, a leading manufacturer of pasta production equipment with the top market share in the world, has developed a fully automatic complete line for Asian noodles aimed at the Asian market. It accommodates various materials, including not only noodles for general instant noodles but also rice flour noodles like pho. It can handle everything from sheet forming to noodle cutting, boiling processes, and frying processes. The dryers developed for various products can be proposed in multiple types depending on the application.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The GEA PAVAN 2-axis extruder achieves continuous and automatic gelatinization by equipping an extruder with a kneader. It is composed of multiple modules below the extruder: - Forward and backward transport, mixing, additive supply, liquid injection, degassing, cooking, and molding. Features: - Executes mixing according to product needs after raw materials are fed in. - The barrel (cylinder) is equipped with various heating and cooling systems. - The supply port can accommodate steam/liquid injection ports or vent ports (at atmospheric pressure and under vacuum as needed). - Independent temperature control, product pressure devices, and interchangeable dies cater to various product needs. - The control system can manage all settings from the feed amount to the cutting unit of the extruder, and recipe registration management is also possible. It widely accommodates gluten-free raw materials, including cereals and snack pellets like cornflakes.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Golfetto, a subsidiary of the globally leading pasta equipment manufacturer PAVAN, offers the best milling equipment. We have a complete lineup, including roller mills, plansifters, and large silos required for storage. All equipment is designed and manufactured in-house and is made in Italy. As this is one of the key areas of focus for PAVAN, we are pleased to offer it at the best price.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a centrifuge that separates high-concentration culture solutions that cannot be handled by intermittent discharge and can continuously discharge the concentrated liquid through a special nozzle. We also have a test machine available, so you can confirm the separation and concentration capabilities before implementation.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We handle a complete set of machinery used for pet food processing lines, combining the technologies of GEA and its subsidiary PAVAN. With years of experience in the food industry and leveraging our own research and development department and pilot plant, we are committed to assisting you in producing the best pet food tailored to your needs. We accommodate various types of products such as kibbles, pillows, and dental sticks. By combining PAVAN's cutting-edge cooking extruders with GEA's advanced meat processing machines, we offer a revolutionary processing line that you won't find elsewhere. We ensure that the formulation of raw materials, product processing, drying, and cooling are all done with care to preserve the flavor, aroma, and quality of the food. Please consider GEA's durable and easy-to-maintain dry pet food processing line.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PAVAN, now under the umbrella of GEA, utilizes over 70 years of extrusion technology for pasta and snacks, handling a complete set of machinery for snack pellet manufacturing lines. Pellet snacks are dried and semi-processed snacks that are easy to store and transport. PAVAN, a world leader in the technology of gelatinization, offers customized solutions based on a tailor-made philosophy. The PAVAN Group boasts three pilot plants and four research production lines within a 2000 square meter facility, enabling all types of inspections, experiments, and development.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

PAVAN, the largest company in the pasta industry now under GEA, utilizes over 70 years of experience to handle a complete set of machinery used in the layered potato chips line. The rich flavor and innovative shapes unique to processed potato chips have led to global growth in consumer demand for this type of product. The entire process, from raw material blending, feeding and mixing, shaping, flavoring, layering of chips, to packaging, is fully automated, enabling stable production.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration