1~45 item / All 45 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~45 item / All 45 items

Filter by category

We will assist you in verifying the electrical characteristics regarding issues you may be experiencing with flash memory (for example, inability to write/read). In addition to component defects, depending on how the flash memory is used, it may not meet the expected reliability or lifespan. (Data corruption or shortened lifespan due to access frequency, access bias, access types, power-on time, surrounding environment, etc.) Our company offers proposals for characteristic verification based on our experience in failure analysis of flash memory tailored to various applications, including laptops, desktop PCs, workstations, and servers/storage.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In recent years, the transition from HDDs to SSDs has rapidly progressed in terms of performance, reliability, convenience, and price reduction. Additionally, to achieve faster, more efficient, and highly reliable data processing, the storage interface has become dominated by NVMe (PCIe). Our company possesses dedicated testers for mainstream NVMe (PCIe) SSDs (compatible with Gen3/Gen4) as well as testing environments for SATA/SAS. Leveraging our experience in handling SSDs for various applications, including laptops, desktop PCs, workstations, mission-critical servers, and storage, we contribute to ensuring the reliability of customer systems.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

On behalf of our clients, we conduct quality audits of parts suppliers and manufacturing contractors. We offer outsourcing of audits tailored to our clients' needs, which includes not only document-related checks and manufacturing process verification but also improvement advice for issues and confirmation of the implementation status of improvement measures.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

It is an electrical component and a mechanical component. Connectors that combine both functions require evaluation tests focusing not only on environmental resistance (temperature, humidity, gas, saltwater) but also on mechanical performance, physical performance, and electrical performance. Eurofins FQL offers product quality evaluations and long-term reliability assessments according to standards. Failure analysis services are also available.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Pressure Cooker Test device can increase the pressure within the test chamber by recreating a water vapor atmosphere under temperature conditions exceeding 100 °C. This test is also known as HAST (High Accelerated Stress Test) and can promote moisture ingress into the sample, allowing for accelerated life evaluation of humidity resistance testing. It also supports the Air-HAST test, which is conducted with residual oxygen in the chamber. ■ Main applicable standards - IEC60068-2-66 (High Temperature High Humidity, Unsaturated Pressurized Water Vapor) - EIAJED4701 (Unsaturated Vapor Pressurized Test) - EIA/JESD22-A110-A (HAST)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Accidents involving products equipped with lithium-ion batteries, such as mobile batteries, are increasing year by year. There are calls for caution regarding the rise in fire incidents caused by lithium-ion batteries due to high temperatures. Lithium-ion batteries are composed of flammable materials and inherently carry the risk of smoke and fire. As secondary batteries have rapidly proliferated, fire incidents have also been on the rise each year. This is not only due to the harshening of usage environments and mechanisms but also because the risks of smoke and fire have not been fully verified. As a third-party verification of battery units, we assess battery performance through tests different from PSE testing: - Nail penetration test (simulating internal short circuits to assess performance) - Heating limit test (heating to thermal limits to assess performance) - 0V charging prohibition protection (assuming recharging after long-term storage) Do you have any of these concerns? - I recognize that it is dangerous, but I don't know what to do. - I lack experience and know-how in evaluation, and I am anxious about ensuring safety. - I want to determine not only safety but also whether the battery has characteristics suitable for the product. - I want to evaluate the product's durability against high temperatures, drops, and impacts to prevent fire incidents in the market.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer accelerated corrosion testing that implements salt spray, drying, and wetting cycles, as well as salt spray composite cycle testing. ■ Main applicable standards - JASO M609 (Corrosion testing methods for automotive materials) - JASO M610 (Corrosion testing methods for the appearance of automotive parts) - JIS XZ2371 (Japanese Industrial Standards) - RTCA/DO-160G (Radio Technical Commission for Aeronautics) In addition to conducting salt spray composite cycle testing, we also accept corrosion analysis and failure cause investigation for electronic components and more.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer testing for the corrosion resistance of electronic components against corrosive gases in accordance with JIS C 60068-2-43 and JIS C 60068-2-60. - JIS C 60068-2-43: Environmental testing methods - Electrical and electronic - Hydrogen sulfide test method for contacts and connections - JIS C 60068-2-60: Environmental testing methods - Electrical and electronic - Mixed gas flow corrosion test* *JIS C 60068-2-60 specifies that copper test pieces should be exposed simultaneously with the samples for corrosion monitoring. At the customer's request, we will simultaneously introduce copper coupons for corrosion monitoring and conduct weight measurements.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Power modules such as IGBTs (Insulated Gate Bipolar Transistors) for high voltage and large current components often contain a significant amount of fillers in the package sealing resin, making it difficult to open the resin. We can remove the package resin using chemical agents for internal observation and, depending on your requirements, conduct evaluations, analyses, and assessments of the internal components after opening. *Please provide a trial sample for opening in advance so we can confirm whether it can be opened (free of charge). *IGBT (Insulated Gate Bipolar Transistor) is a type of power semiconductor capable of high-speed switching for large power.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We would like to introduce environmental testing equipment used for reliability evaluation and environmental testing of not only electronic components and devices but also industrial products and consumer goods materials. Upon consultation, we can place your samples into the testing equipment under specified conditions and provide you with the data and samples after the tests are completed. If you wish to entrust testing to an evaluation organization, do not own testing tanks, or are temporarily unable to use them, please check the equipment specifications when considering outsourcing reliability evaluation tests. *The catalog of equipment specifications listed is only a portion of what we own. For further details, please check our company website.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When power semiconductors and power modules are repeatedly turned ON and OFF, the self-heating and cooling of the components and modules cause distortion due to the differences in expansion of the bonding materials, leading to a deterioration in bonding reliability. We offer power cycle testing that takes into account the heating operation due to repeated self-heating and cooling cycles. ■ Components, units, and devices where the adoption of power semiconductors and power modules is progressing: - Traction inverters for electric vehicles (EVs) and hybrid electric vehicles (HEVs) - On-board chargers and DC-DC converters - Motor control, robots, machine tools, elevators - Industrial inverters and uninterruptible power supplies (UPS) - Solar power generation systems and wind power generation systems

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In response to your company's request for "visualization and quantification" of equipment degradation and product lifespan, we will alleviate the invisible concerns. By visualizing and quantifying the degree of degradation and remaining lifespan of equipment currently in operation and use in the field, you can grasp the timing for maintenance and replacement. This is especially important when using products in special environments that differ from the original installation conditions, as more careful analysis is required. Eurofins FQL, with its extensive experience in the fields of electronic device and component reliability evaluation, failure analysis, and analysis, will assist you in solving challenges by combining various measurement and analysis methods.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

There are many standard tests that are recommended to verify products for sale. For example: - JIS standards (JIS C 60335-1 Safety of household electrical appliances, etc.) - IEC standards (IEC 61960 Batteries for portable devices, etc.) - UL standards (UL 1642 Lithium batteries, etc.) and so on. We undertake public standards applicable to household and commercial electrical products. ■ Do you have any of these concerns? ■ - I want to conduct standard tests on developed or purchased products, but I do not own testing equipment. - A business partner has requested the implementation of standard tests, but I have no experience. - I cannot determine whether the test results from the supplier are appropriate.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We provide high-quality circuit processing and wiring processing services using FIB, including cutting and changing connection points of fine wiring in the lower layers, processing fine wiring located beneath wide power wiring, and the urgent delivery of functioning LSI. - Both AL wiring and Cu wiring can be processed. - We accept orders starting from just one piece. - We will propose the optimal processing points during consultations. - We can accommodate special sample shapes. Please consult with us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Cracks and fractures can occur in products due to various reasons: - Fracture caused by excessive external stress - Fracture due to repeated external stress applied in a specific direction - Fracture caused by the degradation of resin, making it brittle By observing the fracture surfaces of metal and resin materials that have been broken due to external forces, we can estimate the causes that led to the failure.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We accept contracts for reliability evaluations, environmental testing, and safety assessments in accordance with various standards. If any issues arise after implementation, we also conduct cause investigations. Furthermore, based on a standard test, we propose the realization of difficult tests through coordinated control of multiple devices (developing software and test fixtures as needed). ■ Overview Are you giving up on achieving the desired reliability evaluations, environmental tests, and reproducibility tests because conventional testing machines cannot set the desired test conditions or multiple test conditions for reproducing issues? By coordinating control of power supplies, electronic loads, constant temperature chambers, multimeters, bidirectional power supplies, and more, we conduct reliability evaluations, environmental tests, and reproducibility tests tailored to your needs! - We select the necessary equipment for coordinated control based on your requirements and develop a testing plan. - You only need to prepare the test samples. We will prepare other equipment and coordinated control. - We flexibly respond to various sensor integrations and fixture manufacturing as needed. ■ Key Points Even if the evaluation tests you want to conduct cannot be performed with existing testing equipment, it may be possible to realize them by coordinating control with physical wiring switching circuits and various sensors. Please feel free to consult with us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Are there any green or white foreign substances attached to the surface of the gold-plated terminals? This may be a sign of corrosion occurring on the gold-plated terminals. Gold does not corrode, but the underlying metal beneath the gold plating can corrode. Corrosion issues with gold-plated terminals occur when the underlying metal corrodes and deposits on the gold plating. If corrosion products get caught in the connector's mating area, it can lead to poor contact. - There are visible defects on the surface of the gold-plated terminals with green, white, or black foreign substances. - I want to improve corrosion with the supplier, but I cannot obtain evidence of corrosion.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

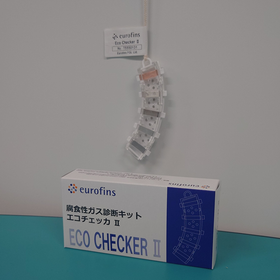

The usage environment of electronic devices varies. The impact of corrosion caused by various environmental factors tends to increase. Corrosive substances generated from hot springs, volcanoes, waste, and rivers can lead to corrosion of electronic components, printed circuit board wiring, connector contacts, and switch contacts in electrical equipment, potentially causing serious troubles. Therefore, investigating corrosive substances in the usage environment is effective for equipment maintenance and ensuring the reliability and lifespan of electronic devices. Our original corrosion environment diagnostic kit, "Eco Checker II," offers a low-cost and simple diagnostic procedure. It allows for easy investigations such as screening for corrosive substances through multi-point surveys. ■ Free Webinar Announcement! ■ We will introduce methods for diagnosing corrosion environments centered around our original corrosion environment diagnostic kit, Eco Checker II. 【Date】 July 22, 2025, 10:00–10:30 【Venue】 Online (Teams) This is recommended for those who are concerned that atmospheric conditions in the operating environment may lead to electronic device failures, or who wish to reduce failure risks in harsh environments such as hot springs or wastewater treatment plants. If you wish to participate, please contact us!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The 8 Disciplines of Problem Solving (8D) is a problem-solving methodology designed to: - Identify the root cause of the problem - Develop short-term solutions - Implement long-term solutions to prevent recurrence of the problem. 8D is an excellent first step to improve quality and reliability when it becomes clear that there are defects in a product or when customer satisfaction is not being met. We can customize the training content to meet your needs, so please feel free to contact us if you are interested.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

There is an increasing number of cases where compliance with the automotive software development process model "Automotive SPICE" is required or becomes a new ordering condition. Additionally, when expanding into embedded software development not only for automotive software but also for existing hardware businesses, a response is necessary. Our company offers various types of seminars tailored to our customers' needs, so please feel free to consult with us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We undertake the investigation of the causes of smoke, fire, and burn damage in electrical and electronic products.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Although it is irregular, we hold "free seminars" on quality technology, including reliability evaluation, analysis, and other topics, several times a year. ■Examples of themes■ We send out announcements of the seminars to customers who have subscribed to our company’s email newsletter. In addition to free seminars, we also provide information about special campaigns and offers. We encourage you to consider registering.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a text sample from popular courses on quality management methods and process improvement education/seminars, including "8D Report Implementation Support," "A-Spice Process Explanation," "STAMP/STPA," and "5 Whys Analysis."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■Safety Evaluation, Lifespan Testing, and Characteristic Evaluation of Battery Units Lithium-ion batteries are composed of flammable materials and inherently carry the risk of smoke and fire. With the rapid proliferation of secondary batteries, fire incidents have been increasing year by year. This is partly due to the insufficient verification of smoke and fire risks. - Not all batteries are subject to PSE (Product Safety Electrical) regulations. - PSE certification tests do not fully verify safety. - Necessary protections may not be included. As a third-party verification of battery units, we assess the battery's capabilities through tests different from PSE testing: - Nail penetration test (simulating internal short circuit to assess capabilities) - Heating limit test (heating to thermal limits to assess capabilities) - 0V charging prohibition protection (assuming recharging after long-term storage) ■Power Supply Unit and AC Adapter Evaluation / Failure Analysis - Safety evaluation of power circuits, wireless power transmission, and USB PD (Power Delivery). - Conducting various noise injection tests to verify noise tolerance and characteristic evaluation in line with power supply specifications. - Evaluation of power supply devices such as power supply units, AC adapters, UPS, and DC-DC converters, including evaluation of the built-in power circuits and verification of power failures.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Based on our consulting experience, we will support the improvement of our clients' development processes by utilizing the know-how we have cultivated so far, using models such as CMMI and Automotive SPICE, to achieve their QCD (Quality, Cost, Delivery) goals.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer onsite and online seminars and e-learning supervised by staff well-versed in quality improvement assurance and activities. ■ Basics of Quality Management System (QMS) This education aims to understand the fundamental concepts necessary to cultivate a quality mindset and an organizational culture that emphasizes quality, as part of building a quality assurance framework. The content is supervised by staff familiar with Quality Management Systems (QMS) to ensure it is easy to understand. ■ Process-Oriented Why-Why Analysis We introduce techniques that can be used in conducting why-why analysis to develop effective preventive measures against recurrence. ■ Thinking About Quality This seminar encourages participants to reconsider the importance of quality that individuals within a company should recognize.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■Methods for Quality Assurance - STAMP/STPA Explanation of specific analysis procedures using case studies along with an overview. Safety analysis methods in an era where reliability concepts based on failure rates, such as FTA and FMEA, are no longer applicable. - Improving Software Quality Software Quality Management Training Introduction to Software Configuration Management ■Enhancing Motivation - Considering Quality - Psychological Safety Seminar - The Power of Ideas Transforms Organizations

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Electronic components and devices installed in vehicles, including ECUs, are expected to be used in harsh environments. Various requirements from international standards (such as IEC-Q100, VDA, IATF16949) as well as unique standards from domestic and international automobile manufacturers are imposed on installed parts and units. On the other hand, in the development of in-vehicle software, there is an increasing need to comply with 'ASPICE', a development process model specialized for the automotive industry, and cases where this becomes a new ordering condition are also on the rise. For in-vehicle components and devices, we offer services for various reliability evaluation tests, environmental tests, durability tests, and failure analysis as required. In software development, we provide support for building development processes that comply with ASPICE and educational programs that explain the requirements of ASPICE.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

■ Analysis of Regulated Chemical Substances in Products - Comprehensive analysis of products and modules, fluorescent X-ray screening, chemical analysis - Analysis of substances contained in RoHS regulations (6 prohibited substances, 4 phthalate esters) ■ Basic Education on Chemical Substance Management in Products - Explanation of the legal regulations regarding chemical substances contained in products, what actions to take to respond to changing regulations, and key points for managing and operating chemical substances in products. ■ Training for Auditors of Chemical Substance Management Systems - Education aimed at improving the diagnostic skills of auditors in CMS - On-the-job training support when diagnosing CMS at customer sites ■ Information Provision Service on Legal Regulations for Chemical Substances in Products - Providing the latest trends in legal regulations for managing chemical substances in products and specific examples of Fujitsu's responses.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The analysis of the root cause is consistently focused on the design and development process, making it easier to derive measures to prevent recurrence. By acquiring fundamental concepts and methods, even those who are new to the "5 Whys" analysis or those who are struggling to conduct it effectively will be able to devise effective measures to prevent recurrence. 【Features】 ■ Explains the factors behind problems occurring in design and development work from a process perspective ■ Avoids difficult expressions and uses many illustrations for an easy-to-read text ■ Customization of group exercise examples is possible according to customer requests ■ Explains the "5 Whys" analysis in five steps, introducing techniques that can be used during the analysis, including key expressions for each step.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We assist in ensuring the quality of your products by reviewing the manufacturing process in response to quality issues such as recalls due to design flaws or component defects, frequent problems in the manufacturing process, and delays in product shipments caused by material procurement issues. This includes detecting issues in the operation of the quality assurance system and its mechanisms, as well as providing support for problem-solving (improvement support). Additionally, we offer educational programs to further strengthen the quality assurance system. *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Eurofins FQL diagnoses the management and operation of chemical substances under the RoHS Directive and REACH Regulation, extracts issues, provides improvement support, and further reduces the risk of content in the supply chain. Utilizing the know-how cultivated through CMS diagnostics for 2,000 Fujitsu business partners, we support the establishment of a system to ensure that non-conforming products are "not accepted," "not produced," and "not shipped," based on the principle of "three realities." We propose the establishment and operation/management methods of a CMS necessary to implement the PDCA cycle, using Fujitsu's unique diagnostic sheet based on JIS Z 7201.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Compliance with "Automotive SPICE," a process model for automotive software development, is required by international standards such as IATF16949 and ISO26262. To promote your company's compliance with international standards in the development process, we provide a one-stop solution tailored to your needs, from process education to official assessment. 【Do you have any of the following concerns or requests?】 ■I want to understand what Automotive SPICE is and first grasp the model. ■I need to comply with IATF16949 and ISO26262 and want to transition the current process to one that meets international standards. ■I have implemented Automotive SPICE, but I am struggling with the development process not taking hold. ■I want to know what is necessary to prepare for an official assessment.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Do you have any concerns about your purchases? - You want to conduct a supplier process audit but lack the resources. - You are using OEM products, but you are worried that 4M changes have been made without your knowledge, resulting in differences from the original specifications. - You are concerned that the products in the market may be counterfeit. - You want to verify the contents of purchased units or parts, but you lack the know-how and equipment, making it difficult to determine if they are genuine. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When products are used outdoors, they are exposed to harsher conditions than indoors, such as ultraviolet rays from sunlight and rainfall. If this environment is simply tested through outdoor exposure tests, it can take a long time to obtain results. We offer weather resistance testing that artificially reproduces indoor and outdoor conditions such as sunlight, temperature, and humidity, allowing for accelerated evaluation of product and material degradation in a short period of time.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In non-destructive analysis, we understand the failure occurrence situation and infer the failure mechanism from visual observation and electrical characteristics. Lock-in infrared thermal analysis When precise location identification is difficult in a non-destructive manner, focusing on heat generation and comparing it with good products is effective. - There are multiple components related to abnormal phenomena, such as mounted circuit boards. - It is unclear whether the short circuit is inside a component or externally at a solder joint. [Examples] - Chip capacitors - Power ICs - Printed circuit boards Ultrasonic flaw detection (SAT) While it is known that delamination inside ICs can be observed, it is also suitable for checking the condition of items composed of multiple materials. [Examples] - Bonding areas of cosmetic panels - Junctions of aluminum heat sinks - Interiors of die-cast products *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We provide one-stop support for long-term reliability evaluation of HDDs/SSDs/removable media, investigation of failure causes that occurred after adoption, and data recovery/deletion. We also accept requests for verification of electrical characteristics for issues with flash memory (e.g., unable to write/read).

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We conduct accelerated degradation tests tailored to your needs, based on our extensive testing expertise and know-how cultivated over many years in quality assurance for various electronic devices, in addition to tests compliant with various public specifications. From the information gathered regarding how the product is used and any issues faced, we will "materialize" and propose accelerated degradation tests suitable for your product. Please feel free to consult us from the component selection and evaluation stage. 【Features】 - In addition to general temperature, humidity, and voltage application, we dynamically and automatically control the applied voltage to be optimal even during insulation degradation, allowing for confirmation of worst-case scenarios after insulation degradation. - In addition to planning and conducting accelerated degradation tests, we can provide one-stop support for everything from identifying insulation degradation points after the test to requests for microscopic imaging of degradation and disconnection points, as well as component analysis. - We possess a wide variety of environmental test chambers and evaluation equipment.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Experts in various components such as semiconductors, cables and connectors, printed circuit boards, display devices like LCDs, power units, batteries, AC adapters, and memory will conduct failure analysis. - Perform semiconductor package resin opening, and estimate causes through observations using optical microscopes, emission microscopes, and scanning electron microscopy (SEM) with mechanical polishing. - From the perspective of material analysis, estimate causes through processing and observation using focused ion beam processing observation equipment (FIB-SEM), and observation using transmission electron microscopy (TEM) for material condition, foreign matter identification, surface/break analysis, etc. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We offer package opening for ICs using copper (Cu) wires, silver (Ag) wires, and more, utilizing our uniquely developed method to minimize wire dissolution and damage. We also accept package opening for resin-sealed power modules, such as high-voltage and high-current components like IGBTs, which are difficult to open due to the high content of fillers.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Eurofins FQL Co., Ltd. has its origins in the analysis division of Fujitsu Laboratories Ltd. and the quality assurance department of Fujitsu Ltd. It has been engaged in activities to improve product quality for a long time, not only in material analysis, reliability evaluation, safety assessment, and failure analysis, but also in supplier quality management and manufacturing plant audits. Additionally, it contributes to solving challenges faced by organizations responsible for quality through the development and educational support of personnel involved in quality, as well as the construction and improvement of quality management, product chemical substance management systems, and software development processes. ■ Reliability Evaluation and Environmental Testing Various reliability evaluations, safety verification of secondary batteries, power supplies, etc., including smoke and fire hazards. Evaluation of special environments such as weather resistance and gas corrosion. ■ Failure Analysis Failure analysis of electronic components and devices, confirmation of characteristics related to materials, and detailed analysis of defects. ■ Support for Building and Improving Quality-Related Systems and Processes To achieve QCD (Quality, Cost, Delivery) goals, we support the improvement of development processes using models such as CMMI and Automotive SPICE. ■ Quality-Related Education Customizing educational programs for needs such as "wanting to energize the organization," "wanting to cultivate a quality mindset," and "wanting to provide quality education for new employees."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company offers "reliability evaluation/environmental testing" services. We own over 100 testing machines and chambers, including thermal shock testers and gas corrosion testers. We can accommodate a wide variety of tests tailored to your needs, from standard-compliant tests to lifespan limit tests, as well as providing rental of testing chambers and conducting customized tests. Please feel free to contact us. 【Available Reliability Tests / Environmental Tests (partial list)】 ■ Thermal Shock Test (Gas Chamber / Liquid Chamber) ■ High Temperature and High Humidity Storage Test ■ Gas Corrosion Test ■ Accelerated Weather Resistance Test ■ Vibration Test ■ Salt Spray Test ■ Safety Tests (Crush Test, Heating Test, Charge/Discharge Test)

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Eurofins FQL provides failure analysis for a variety of products, from circuit components such as semiconductors, printed circuit boards, and connectors to OEM and ODM products. If you have concerns such as "I want to conduct failure analysis but do not have sufficient equipment" or "I have doubts about the manufacturer's failure analysis report," please feel free to contact us. 【Leave it to us】 ■ Investigation Plan: Understanding failure phenomena and planning analysis methods to confirm usage conditions ■ Non-destructive Analysis: Narrowing down abnormal areas non-destructively ■ Destructive Analysis: Estimating causes through observation and analysis of the occurrence of abnormalities ■ Summary of Results: Summarizing analysis results and proposing improvements *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Even if the cause of a failure or manufacturing defect is on the scale of just a few atoms, Eurofins FQL will pursue it. Based on insights from analytical instruments that examine sizes on the scale of a few atoms, including transmission electron microscopes, we support the improvement of product quality. If you have concerns such as wanting to identify the nature of foreign substances attached to products or parts but don't know how to proceed, please feel free to contact us. 【Features】 ■ Pursuing the cause of failures or manufacturing defects even if it is on the scale of just a few atoms ■ Supporting product quality improvement based on insights from analytical instruments that examine sizes on the scale of a few atoms, including transmission electron microscopes, and knowledge of the materials themselves.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We provide support for improving equipment management and quality issues related to corrosion from two perspectives: corrosive environments and corrosion resistance. - Diagnosis of corrosive environments in equipment and workplaces through the use and analysis of corrosion environment diagnostic kits (Eco Checker II, Eco Checker SUN) - Enhancing maintenance efficiency of equipment by visualizing the deterioration status of products in operation - Evaluation of product corrosion resistance - Salt damage investigation - Salt spray testing (composite cycle) - Gas corrosion testing - Temperature and humidity testing

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration