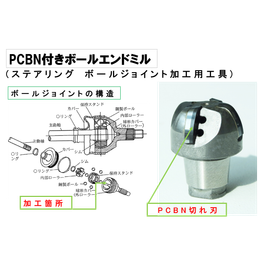

2-flute ball end mill (high hardness)

100% German materials, applicable for 45HRC to 70HRC.

1. The base material uses ultra-fine particle carbide made in Germany. 2. Base material hardness: 94HRA (HV30 = 1930N/mm²). 3. Flexural strength: over 3900N/mm² (TRS > 3900N/mm²). 4. Processed with a CNC 5-axis controlled grinding machine made by Walter in Germany. 5. ALDURA coating. 6. Recommended for high hardness and high-speed cutting processing.

- Company:HKF 虹鋼富企業有限公司(HKF カッティングツール) 台湾本社

- Price:Other

![Multi-blade diamond face mill for aluminum [regrindable type, head exchangeable type]](https://image.mono.ipros.com/public/product/image/476/2000711805/IPROS37734340870543454743.jpeg?w=280&h=280)