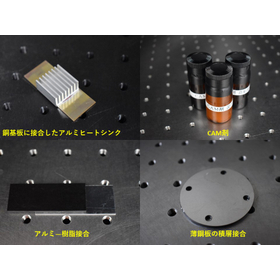

Metal/Hybrid Material Joining Technology 'DLAMP'

Adaptable to various metals! Achieved high bonding strength through the anchor effect.

"DLAMP" is a groundbreaking technology that firmly bonds metals and dissimilar materials through a completely dry process using lasers. After treating the metal surface with a laser, dissimilar materials are poured in, achieving high bonding strength due to the anchoring effect. In-house processing of DLAMP treatment is also possible through technology licensing. 【Features】 ■ Adaptable to various metals ■ Partial processing is possible (one-sided treatment, patterning) ■ Low running costs (no waste liquid or consumables generated) ■ Shorter processing time compared to pulse waves, with higher tensile strength *For more details, please refer to the PDF document or feel free to contact us.

- Company:ノバセル 大阪地区

- Price:Other

![[Technical Data] Reduced Temperature Variation! High-Performance Water-Cooled Microchannel Heat Sink](https://image.mono.ipros.com/public/product/image/e55/2000799714/IPROS17018670593636658481.PNG?w=280&h=280)

![[Information] Types and Features of Die Casting <2020 Edition>](https://image.mono.ipros.com/public/product/image/3cf/2000521734/IPROS98029015841288144723.jpeg?w=280&h=280)