1~14 item / All 14 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Inquiry Form1~14 item / All 14 items

Recent circuit boards are equipped with a wide variety of components, including extremely small chip components, large components, as well as module boards and BGA packages. Since each component has a different thermal capacity, by the time the temperature of the larger components rises, it may exceed the heat resistance temperature of the smaller components, potentially causing defects. If such occurrences happen frequently, it could also affect the yield. Our reflow equipment can rapidly increase the temperature on the heating plate and is designed to avoid overshoot, thereby reducing thermal stress on printed circuit boards and mounted components. Additionally, the entire heating plate is automatically controlled to maintain a uniform temperature, which helps minimize temperature variations affecting the target objects, such as circuit boards. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When molten solder takes too long to cool and solidify, it negatively affects the solder joint strength and electrical characteristics. It is a problem if the characteristics deteriorate due to cooling speed issues. Our reflow equipment is equipped with an active water cooling system using circulating cooling water as standard. This allows us to maximize the solder characteristics after reflow. [Case Summary] ■ Issue: If the molten solder takes too long to cool and solidify, it negatively impacts the solder joint strength and electrical characteristics. ■ Solution: - Standard equipped with an active water cooling system using circulating cooling water. - This not only improves the strength and electrical characteristics of the solder but also reduces the tact time. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Until now, we have been using flux to remove the oxide film, but if it remains on the substrate (flux residue), it eventually corrodes and causes failures such as loss of electrical conductivity and soldered components detaching. Recently, as structures have become more complex, there has been a concern about whether the cleaning solution reaches all areas, making it impossible to eliminate the risk of flux residue. Our company supports solder reflow using a "reduction method" with formic acid and hydrogen. This allows for the removal of the oxide film without using flux, thus preventing flux residue and, of course, eliminating the need for a cleaning process. [Case Summary] ■Issue - Flux was used, but if it remains on the substrate (flux residue), it causes failures. ■Solution - Ensured solder wettability without using flux through reduction method reflow. - Choosing formic acid reduction allows for easy equipment and running costs, achieving flux-free and cleaning-free solder reflow. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

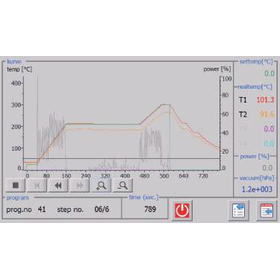

When X-raying the state after the solder has solidified, there are cases where something resembling bubbles appears within the solder, which is referred to as "voids." If the solder solidifies with these voids remaining, the joint strength and electrical characteristics deteriorate. It is essential to ensure that voids are removed during the process. Our reflow equipment can accommodate a vacuum (reduced pressure) environment of up to 10^-3 hPa, allowing for the evacuation of voids. It is possible to create a profile that allows for the solder to be heated to its melting point after establishing a vacuum state, and also to perform vacuum evacuation while the solder is in a molten state. [Case Overview] ■ Issue - If the solder solidifies with voids remaining, the joint strength and electrical characteristics deteriorate. ■ Solution - By performing vacuum evacuation (reduced pressure) while the solder is molten, voids can be actively removed from the molten solder. *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "RSS-160" is a solder reflow device capable of heating at a rate of 100K/min using a cartridge heater. It supports Φ6 inch and 150mm square sizes, achieving lead-free, voidless, and fluxless soldering. It can handle various reflow environments including atmosphere, nitrogen, vacuum, formic acid, and hydrogen with a single unit. 【Standard Hardware Specifications (Partial)】 ■ Effective object size (W×D×H): 155mm×155mm×35mm ■ Maximum reachable temperature: 400℃ ■ Maximum heating rate: 100K/min (approximately 1.7K/sec) ■ Heating method: Cartridge heater ■ Maximum cooling rate: 100K/min (T=400℃>200℃) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "RSS-110" is a solder reflow device that achieves lead-free, void-free, and flux-free soldering. Equipped with a multifunctional touch panel, it can handle various reflow processes such as air, nitrogen, vacuum, formic acid, and hydrogen with a single unit. The device dimensions are 260×420×220mm (W×D×H), and the weight is approximately 10kg. 【Standard Hardware Specifications (Partial)】 ■ Effective object size (W×D×H): 105mm×105mm×35mm ■ Maximum reachable temperature: 400℃ ■ Maximum heating rate: 120K/min (2K/sec) ■ Heating method: Cartridge heater ■ Maximum cooling rate: 180K/min (T=400℃>200℃) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "RSS-3X210-S" is a solder reflow device that supports both formic gas and hydrogen gas reduction, with enhanced safety features. It can process up to 12 wafers with a diameter of 100mm at once, and is also suitable for reflowing elongated objects such as printer heads and LED lighting. Equipped with 18 high-speed infrared (IR) heaters under the hot plate, it maintains a uniform temperature even in a wide effective heating area, achieving stable heating that is less affected by the heat capacity of the objects. 【Features】 ■ Effective heating area: 630mm x 210mm ■ Equipped with high-speed infrared (IR) heaters ■ Standard 7-inch touch panel ■ Active water cooling system ■ Capable of setting various reflow environments, including vacuum, formic acid, and hydrogen *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "RSO-300/200" is a multifunctional solder reflow device that can handle various reflow processes such as atmospheric, nitrogen, vacuum, formic acid, and hydrogen with a single unit, equipped with a touch panel. By equipping the bottom of the hot plate with a cross arrangement of 12 vertical and 12 horizontal high-speed infrared (IR) heaters, it achieves stable heating and rapid temperature rise that is less affected by the heat capacity of the target object. In addition to standard reflow, it is also suitable for sintering metal nanopaste and other materials. 【Features】 ■ High-purity quartz chamber: Optional ■ Cross arrangement: Equipped with high-speed infrared (IR) heaters ■ Standard 7-inch touch panel ■ Cooling by nitrogen purge ■ Capable of setting various reflow environments, including vacuum, formic acid, and hydrogen *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "HPP-155/HP-220" is a high-precision programmable hot plate developed for those who want to perform reflow easily while maintaining high accuracy in temperature control for small-scale experiments and prototypes. It retains high performance features such as nitrogen purge and a 16-step temperature programming function, while only including the necessary functions. Setup is simple, allowing for easy use across a wide range of applications. 【Features】 ■ High temperature control capability with P.I.D control ■ Compatible with nitrogen purge environments ■ Capable of setting a 16-step temperature program ■ High uniformity in heating without unevenness ■ High temperature control capability with zero overshoot *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "AZ9T/AZ9C" is a 10X optical zoom microscope capable of real-time observation and recording within the chamber. It achieves a working distance (WD) of 90mm, optical 10x zoom, and a resolution of 3μm. Even when viewed through the quartz glass observation hole of the reflow unit, it appears sharp and clear. The advantages of a wide-field, long working distance stereo microscope and high-resolution observation with coaxial illumination from a metal microscope have been integrated into the A29 compact body. 【Features】 ■ Achieves a working distance (WD) of 90mm, optical 10x zoom, and a resolution of 3μm ■ Easy installation by simply connecting the PC and camera unit ■ Records and observes in sync with the program operation of the reflow unit ■ Data can be saved to the PC not only as still images but also as videos *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "RTP/VPO series" is a tabletop type high-speed annealing device for vacuum and process gases. It includes models such as "RTP-150," which is suitable for research and development requiring high purity and stability, such as the thermal oxidation process of SiC and crystal growth of GaN, as well as "RTP-100" and "VPO-1000-300." 【RTP-150 Features】 ■ Compatible with 6-inch wafers ■ Maximum achievable temperature of 1000℃ ■ Achieves linear temperature control ■ Significantly reduces the occurrence of contamination ■ Options available to accommodate various experimental environments *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The "VSS-450-300" is a tabletop vacuum solder reflow device that flexibly accommodates various applications, including solder reflow, oxidation-reduction processing, and paste sintering. With an effective heating area of 300×300×50mm, it can easily handle the mounting of tall components. 【Features】 - Compatible with both fluxless solder (reduction method) and flux-containing solder - Achieves a maximum temperature of 450°C despite its tabletop size - Standard support for atmospheric reflow, nitrogen gas purge reflow, and vacuum reflow - Optional support for formic acid reduction reflow and forming gas (hydrogen + nitrogen) reflow - Supports rapid cooling through a water cooling system *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is a tabletop vacuum solder reflow device compatible with both formic acid and hydrogen reduction. Despite its compact size, which is among the smallest in the industry, it supports atmospheric, nitrogen, and reducing atmospheres (formic acid or hydrogen), as well as vacuum reflow. Additionally, it features rapid heating and cooling through a water cooling system, making it suitable for research and development or prototyping. It flexibly accommodates various applications, including solder reflow, reduction treatment of metal oxide films, and sintering of paste materials. **Features** - Achieves zero flux residue by removing oxide films without using flux. - Reaches a maximum temperature of 400°C despite its tabletop size. - Standard support for atmospheric reflow, nitrogen gas purge reflow, and vacuum reflow. - Supports rapid cooling through a water cooling system. - The working area is gas shielded, allowing for use in processes sensitive to contamination and other critical processes. *For more details, please refer to the PDF document or feel free to contact us.*

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This catalog introduces the vacuum solder reflow devices handled by Unitec Japan Co., Ltd. Starting with the "VSS-450-300," which allows for easy temperature profile settings and is suitable for both small-batch production and mass production, we also feature models like the "RSS-210-S" and "RSS-160-S," which come standard with a viewing window and are perfect for research and development or prototyping. [Contents (excerpt)] ■ VSS Series ■ RSS Series ■ RSO Series *If you would like a copy of the catalog, please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration