[Technology Introduction] Direct Gold Plating

Introduction to direct gold plating on materials

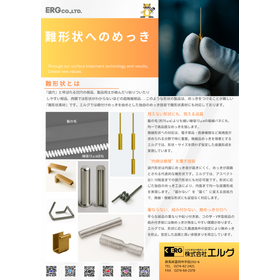

Elg Co., Ltd. handles various materials and specializes in precision plating for smaller components through surface treatment technologies and results. Direct gold plating is a method of applying gold plating directly onto the material without nickel plating or similar processes. It is suitable for medical applications and for addressing nickel allergies. Additionally, chemical polishing treatments tailored to specific purposes, such as deburring for pressed parts, thin materials, and roughening, are available. 【Materials compatible with direct gold plating】 ■ Titanium ■ Tungsten ■ Stainless steel *For more details, please refer to the PDF document or feel free to contact us.

- Company:ERG

- Price:Other

![[Technology Introduction] Direct Gold Plating](https://image.mono.ipros.com/public/product/image/2000346620/IPROS3877885474527809150.png?w=280&h=280)

![Excellent corrosion resistance and resistant to discoloration [Nickel plating] *Available from one piece](https://image.mono.ipros.com/public/product/image/889/2000374855/IPROS34724670435627864246.jpeg?w=280&h=280)

![Gold Plating Explained by Hori: [Q&A on Plating You Can't Ask Now] *Materials Provided](https://image.mono.ipros.com/public/product/image/b5c/2000419843/IPROS90513100883126897404.png?w=280&h=280)