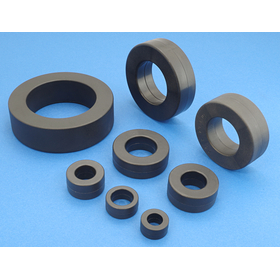

Dual-structure core for reducing roll tendency and shaft diameter conversion (Lotus Core)

Keep the existing shaft (for 3 inches) and increase the outer diameter to 6 inches/8 inches! Reduce the curling tendency of films and labels during the process!

The "Lotus Core" can reduce the curling of films and labels! It is mainly used for winding separator films and in the winding processes of tack labels and tack seals. It is also effective for winding semi-finished products before they are cut into sheets. With existing equipment, it is possible to increase the winding diameter (6 inches/8 inches). It addresses cost issues related to equipment modifications and dummy winding of products. The more expensive the film, the greater the expected improvement! It prevents the deterioration of film performance caused by "curling" and "strong winding pressure" that occur during the winding process.

- Company:昭和丸筒

- Price:Other

![[Production Example] Laminated Motor Core (φ110×35×0.2mm)](https://image.mono.ipros.com/public/product/image/578/2000624165/IPROS26687308680061618932.jpeg?w=280&h=280)

![[Production Example] T-shaped 6-link laminated motor core (Poki-Poki Core)](https://image.mono.ipros.com/public/product/image/85b/2000624166/IPROS25661592644798061833.jpeg?w=280&h=280)

![[Production Example] Laminated Core Prototype (φ150)](https://image.mono.ipros.com/public/product/image/c68/2000624178/IPROS55307690268900804509.jpeg?w=280&h=280)

![[Production Example] Motor Core (φ110×0.2mm)](https://image.mono.ipros.com/public/product/image/55b/2000632513/IPROS48345141141119430728.jpeg?w=280&h=280)

![[Production Example] Stator Core (φ300×0.25mm)](https://image.mono.ipros.com/public/product/image/13b/2000632525/IPROS26642459945738250319.jpeg?w=280&h=280)

![[Cost Reduction] High-Performance Film Winding Core 'e-Core'](https://image.mono.ipros.com/public/product/image/38a/2000542541/IPROS63205368062565718863.png?w=280&h=280)