High Brightness LED Light Through Hole Light

Professional-grade through-hole light that allows you to see deep into processed items, inside machines, and into narrow spaces!

High-brightness LED light through-hole light is professional-grade, allowing you to see deep into workpieces, inside machines, and in tight spaces! The head tip is covered with a SUS cover, making it shock-resistant and preventing damage to workpieces. The cable is made of SUS flexible material, making it durable and resistant to wear. It is ideal for inspecting workpieces and the interiors of machines. For more details, please contact us or refer to the catalog.

- Company:ジョインツール

- Price:Other

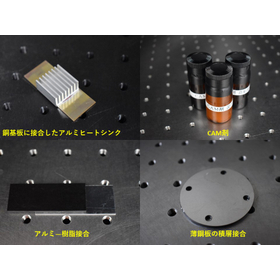

![[Production Example] Stiffener](https://image.mono.ipros.com/public/product/image/836/2001020554/IPROS53503215459234692760.png?w=280&h=280)

![[Equipment Introduction] Tools](https://image.mono.ipros.com/public/product/image/053/2001020633/IPROS73545280872655408350.png?w=280&h=280)

![[Technical Data Presentation!] Main Component Diagram of Crowning Molding Die](https://image.mono.ipros.com/public/product/image/4d5/2001133231/IPROS88170698774838941885.jpeg?w=280&h=280)

![[Technical Data Presentation!] Main Structure Diagram of Dental Forming Mold](https://image.mono.ipros.com/public/product/image/34d/2001133236/IPROS44043431769059450911.jpeg?w=280&h=280)