91~135 item / All 154 items

Displayed results

Filter by category

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us Online91~135 item / All 154 items

Filter by category

For those considering an image processing inspection system using AI, by combining a highly proven system with flexible inspection capabilities of AI, we will reliably eliminate defective products. Various analysis results utilizing AI have been introduced in various media, and we have increasingly received inquiries about whether AI can be used for inspections in the field of visual inspection. Additionally, many companies have released AI software, often claiming that it can be implemented with relatively simple operations. However, AI (artificial intelligence) can only analyze data when it is provided with appropriate knowledge (information). Therefore, when using AI for visual inspections, it is necessary to register information about both good and defective products, and by repeating this process, the AI learns the differences between good and defective products, enabling it to make judgments. Furthermore, when conducting inspections with AI, it is essential to accurately capture the state of defects, which requires the use of "appropriate cameras" and "selection of lighting." 【Features】 ■ Combination of AI that allows for flexible inspections ■ Reliable elimination of defective products ■ Introduction of AI inspections based on rule-based inspections ■ Improved accuracy in eliminating defective products *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This is an inspection device equipped with a camera and lighting on a general-purpose XYZ axis operating stage. Unlike typical manual inspection devices that require setting each item to be inspected individually on the stage, this device allows for inspection of workpieces arranged on a tray by moving the stage and camera, enabling inspection of larger workpieces or an entire tray that cannot be captured in a single image. Additionally, by utilizing a general-purpose stage, it can be used as a relatively compact and cost-effective device. *First, we will verify whether the workpieces you wish to inspect are suitable for inspection. *For more details, please download and check the catalog.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Don't you think that automating inspections using microscopes and magnifying glasses is difficult? iVision Scope is a system that can project images captured by a camera using a microscope onto a screen and automatically determine the results. Additionally, by combining it with an automatically operating stage, it is possible to inspect the workpiece sequentially from the edge and save images showing the location and type of defects found. *First, we will verify whether the workpieces you wish to inspect are suitable for inspection. *For more details, please download the catalog and check.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The 3D sensor is a system that measures the distance to the target, allowing for the inspection of surface defects and three-dimensional structures. To operate this function correctly, it is necessary to use it as a stable inspection device. D-Measure is a system that integrates a 3D sensor into a general-purpose XYZ-axis operating stage, making it compact and capable of accommodating various inspections. Additionally, it allows for various customizations tailored to the customer's inspection objects, enabling operation as a complex inspection device combined with other inspections. If you are considering inspections using a 3D sensor, please let us know; we would love to hear from you! *First, we will verify whether the work you wish to inspect is feasible. *For more details, please download the catalog and check it.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When conducting inspections of films and liners transported in roll-to-roll systems, have you ever decided against automating the inspection due to the high speed of the line? iVision High Speed enables inspections at high speeds that were previously not possible. It is also capable of recording the distance from the starting position and detailed images of defects, as well as issuing instructions to the line. *First, we will verify whether the work you wish to inspect is feasible. *For more details, please download the catalog and check.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

When imaging the inner surface of a workpiece shaped like a cup, there is no need to rotate the workpiece or insert a camera inside it. In conventional methods for imaging the inner surface of cylindrical components using traditional lenses, it was necessary to either rotate the workpiece or surround it with multiple cameras, as the technique involved capturing part of the inner surface from an angle. Even when using devices like endoscopes, complex mechanisms were required, such as inserting the endoscope into the interior of the workpiece. To address such issues, using a special lens allows for viewing the interior from the outside of the workpiece. 【Basic Specifications】 - Wide Field of View Since it can inspect the entire 360° surface of the interior of the object at once, there is no need to rotate the workpiece. - Deep Depth of Field It can simultaneously inspect not only the inner wall surface but also the bottom surface. - Inspection from the Outside Unlike devices that require inserting a lens inside, it can capture images from the outside all at once. - Easy Installation, Space-Saving Unlike conventional imaging from an angle, it captures images directly from above, eliminating concerns about the angle.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In the inspection of transparent glass, resin products, and films, have you ever been turned down for the introduction of automatic inspection due to the difficulty of detection? By innovating imaging methods and lighting, it has become possible to inspect transparent materials that were difficult to detect with conventional image processing systems. If you are looking for automatic inspection for products like glass and films, this is a feature you should definitely check out! If you are having trouble with automatic inspection of transparent materials like glass and films, please feel free to consult with us. *First, we will verify whether the work you wish to inspect is feasible. *For more details, please download the materials and check them.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Titan SFTP Server is server software that provides a reliable and secure file transfer solution sought by businesses. It allows for easy creation and operation of an SFTP server on Windows, receiving high praise from companies around the world for its precise configuration control, simple user interface, and excellent cost performance. As an on-premises server software, its annual costs are also low and clear. Titan SFTP, the SFTP server, is equipped with excellent security features, providing secure file transfers to companies worldwide. It supports public key authentication using public and private keys, and it is also possible to create a whitelist to deny unauthorized access from external sources. Additionally, it protects important data from risks such as data tampering and information leakage through features like DoS attack defense and automatic blocking of IP addresses attempting unauthorized access.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

"DiffDoc" is software that can compare two files, such as Word files and PDF files, and detect differences.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Convert Doc allows for seamless conversion between PDF, Word, HTML, rich text, and text, such as from PDF to Word and from Word to HTML.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

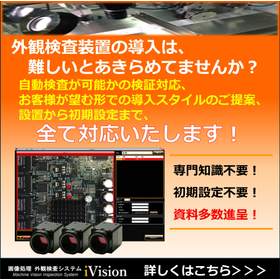

Do you have any of these concerns? - Are you worried that your company's products can be automatically inspected? - Is the installation environment limited, making implementation difficult? - Are there many technical terms, making it hard to understand what needs to be checked? - Is it difficult to secure personnel for initial setup? The image processing visual inspection system "iVision" can solve these problems! The image processing visual inspection system "iVision," developed by our company, is a product we highly recommend for those who are anxious about automating visual inspections. "iVision" is built with hardware and software that allows imaging in a verified environment prior to implementation, and we deliver it in the form desired by the customer. Additionally, our staff will perform the initial setup upon delivery and will assist until it operates correctly. 【Features】 - We build an imaging environment that reliably detects defects through prior verification! - We offer full customization according to the customer's wishes, from fully automated devices to inline solutions! - With on-site adjustments by our staff at the time of delivery, no customer setup is required! - We also provide remote support for any issues after delivery!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Do you have any of these concerns? - Is it true that the AI that has been in the spotlight recently can perform any kind of inspection? - I want to introduce an inspection device using AI, but can it be easily implemented? - I've heard that AI needs to be trained initially; how does that work? The image processing visual inspection system "iVision" can solve these concerns! Our company leverages years of experience in inspection device development to utilize the advantages of both AI and existing automatic inspections, allowing us to deliver solutions tailored to our customers' needs. First, we confirm what the customer wants to inspect and in what condition, then consider the appropriate cameras and lighting, and based on that, we will propose the necessary inspection device. 【Features】 - Inspection from multiple directions: Connect multiple cameras to inspect various areas! - Multiple inspections: Perform several inspections simultaneously, such as defect inspection and dimensional inspection! - Expandability of inspections: New inspections and functions can be added even after implementation! - Reliable implementation support: We will handle initial support to ensure that the results of pre-verification are reflected!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Would you like to consider a dream-like inspection system where humans and robots collaborate on tasks? We will provide a detailed introduction to the features of collaborative robots that can work alongside humans, the inspection systems utilizing them, and the benefits of implementation! Our company proposes an inspection system that works in conjunction with robots as one of various inspection systems. Please take a moment to read the materials. [Contents] ■ What is a collaborative robot? ■ Collaborative robots integrated with image processing inspection ■ Benefits of implementation *For more details, please refer to the PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

To those involved in the manufacturing of bottled beverages and similar products, we have a proposal for an inspection device that can be installed later! By attaching a camera to your existing manufacturing and transport line, it is possible to conduct inspections for cap float, liquid filling amounts, label adhesion conditions, and printed inspections on boxes after packaging, all at once. 【Features of this system】 - Cameras can be attached to existing manufacturing and transport lines, enabling inline inspections. - Multiple inspections, such as cap float and label adhesion, can be conducted simultaneously. - If additional inspections are required, those functions can be added. *First, we will verify whether the work you wish to inspect can be accommodated. *Detailed information is provided in the attached PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

3D sensors can project lasers onto objects and capture the surface conditions in three dimensions based on the reflections. While visual inspections using cameras can detect various conditions of the target, they struggle with height variations. By combining these two technologies, inspections that were previously difficult to address can now be performed. At AdD, we also handle consultations on various challenges using 3D sensors. [Contents] ■ What is a 3D sensor? ■ Comparison between image processing inspection and 3D sensors ■ What types of inspections can be performed? *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

For those manufacturing electronic components and small parts that require inspections at multiple locations, we propose an appearance inspection device that conducts inspections at various points using a multi-axis robot!! This inspection device is designed to simultaneously capture and inspect the surfaces of four parts created at once by a molding machine, both front and back, in a single operation, classifying and discharging each as either OK or NG!! 【Features of this system】 ■ Inspection system utilizing a multi-axis robot ■ Allows inspection of different locations by having the robot hold the workpiece ■ Separates and discharges OK and NG parts through robot handling. *First, we will verify whether the workpiece you wish to inspect can be accommodated. *Detailed information is provided in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A proposal for an appearance inspection device that performs inspections and stacking after inspection for those manufacturing food trays using pressing or air pressure molding!! We propose a system that installs transport devices for each lane for trays discharged from the molding machine in multiple lanes. Each lane inspects the outside and inside of the trays, expels defective ones, and stacks only the good products!! 【Features of this system】 ■ High-speed inspection using multiple lanes ■ Complete automation that expels defects individually and stacks only good products ■ Labor-saving through a consistent inspection system from production *First, we will verify whether the work desired by the customer can be inspected. *Detailed information is provided in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The 3D CAD software VariCAD has an initial setup cost starting from around 130,000 yen (including tax) with one year of support and upgrades, making it affordable. The running costs from the second year onwards are in the 50,000 yen range, which includes one year of maintenance support and a license for upgrading to the latest version. Additionally, since it is a one-time purchase license, you can continue to use VariCAD even after one year from the purchase. VariCAD comes equipped with various basic tools such as batch conversion from 3D to 2D drawings, creation of sheet metal unfolding diagrams, calculation functions for machine parts, and a library of machine parts, all featuring a user-friendly interface. Furthermore, a viewer software is provided free of charge, allowing customers to directly check CAD data and design images, facilitating smooth meetings with clients. Additionally, a discount coupon of 5,000 yen is currently being offered exclusively to Ipros members who download the catalog. ■ Download the 30-day free full-feature trial version here: https://varicad.add-soft.jp/download/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

VariCAD, a 3D CAD software, supports input and output in the intermediate STEP file format, output to image file formats, and input and output of AutoCAD's 2D DWG/DXF. It also allows for easy hiding of solids that you don't want your clients to see and simple output of cross-sectional data. In 2D, data can be output depending on the version of AutoCAD, and layer settings are straightforward. A free viewer is also distributed, allowing clients to check the data. VariCAD is the ideal CAD software for beginners seeking low-cost yet high-functionality 3D CAD. In addition to file compatibility, cross-sectional display, and hiding features, VariCAD includes various basic tools such as batch conversion from 3D to 2D drawings, creation of sheet metal development drawings, and calculation functions for mechanical parts, all at a low price starting from around 130,000 yen including one year of support. Furthermore, we are currently offering a 5,000 yen discount coupon exclusively for Ipros members who download the catalog. ■Download the 30-day free full-feature trial version here↓↓↓ https://varicad.add-soft.jp/download/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

VariCAD, a 3D CAD software, makes it easy to create and edit assemblies. It allows for simple linking of part files and assembly drawing files, enabling easy reflection of edits made in both on the drawing data. This can reduce work time and improve efficiency. VariCAD is the ideal CAD software for beginners looking for a low-cost yet high-functionality 3D CAD solution. In addition to assembly features, VariCAD includes various basic tools such as batch conversion from 3D to 2D drawings, creation of sheet metal unfolding drawings, and calculation functions for mechanical parts, all available at a low price starting from around 130,000 yen including one year of support. Additionally, for Ipros members who download the catalog, we are currently offering a discount coupon of 5,000 yen. ■ Download the 30-day free full-feature trial version here↓↓↓ *You can download it easily without registering customer information. https://varicad.add-soft.jp/download/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

VariCAD, a 3D CAD software, allows for easy batch conversion to DXF, DWG, and STEP files. It also supports batch conversion to IGES and STL formats. This reduces work time and increases efficiency. Additionally, it can output files compatible with different versions of AutoCAD. Output formats: STEP format (3D), STL format (3D), IGES format (3D), DWG format (2D), DXF format (2D) Input formats: STEP format (3D), DWG format (2D), DXF format (2D) VariCAD is the ideal CAD software for beginners seeking low-cost yet high-functionality 3D CAD. In addition to its batch conversion feature, VariCAD includes various basic tools such as batch conversion from 3D to 2D drawings, creation of sheet metal unfolding drawings, and calculation functions for mechanical parts, all at a low price starting from around 130,000 yen including one year of support. Furthermore, we are currently offering a 5,000 yen discount coupon exclusively for Ipros members who download the catalog. ■ Download the 30-day free full-feature trial version here↓↓↓ https://varicad.add-soft.jp/download/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

VariCAD, a 3D CAD software, can output data in the .STL format used by 3D printers. By loading the 3D data output from VariCAD into a 3D printer and printing it, you can complete a 3D printed item. VariCAD is the ideal CAD software for beginners looking for low-cost yet high-functionality 3D CAD. In addition to the data output function for 3D printers, VariCAD includes various basic tools such as batch conversion from 3D to 2D drawings, creation of sheet metal development drawings, and calculation functions for mechanical parts, all at a low price starting from around 130,000 yen including one year of support. Furthermore, for Ipros members who download the catalog, we are currently offering a discount coupon of 5,000 yen. ■ Download the 30-day free full-feature trial version here↓↓↓ *You can download it easily without registering customer information. https://varicad.add-soft.jp/download/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features of VariCAD products: - Easily check for interference by calculating the distance between solid models. - Interference points that are difficult to find in 2D drawings can be detected in 3D models, preventing setbacks in later manufacturing processes when interference is noticed. In addition to the interference check function, VariCAD includes various basic tools such as BOM creation, sheet metal unfolding, mechanical part calculation functions, and assembly functions, all available at a low price starting from around 130,000 yen including one year of support. Furthermore, for Ipros members who download the catalog, we are currently offering a discount coupon of 5,000 yen. *Download the 30-day free trial version here: https://varicad.add-soft.jp/download/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features of 3D CAD VariCAD - By registering the drawings you want to print in a list, you can print multiple drawings at once. - Once registered in the print list, there is no need to set up printing for each individual file; files in the list can be printed without opening them one by one. This significantly reduces the time and effort required when you need to print a large number of drawings. In addition to the batch printing feature, VariCAD comes equipped with various basic tools such as BOM creation, sheet metal unfolding, mechanical part calculation, and assembly functions, all at a low price starting from around 130,000 yen including one year of support. Furthermore, for Ipros members who download the catalog, we are currently offering a discount coupon of 5,000 yen. *Download the 30-day free trial version here: https://varicad.add-soft.jp/download/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features of 3D CAD VariCAD - Automatically calculates volume, mass, surface area, and center of gravity with the push of a button. - Easily measure by defining materials and assigning material (mass density) to solids with just a click of a button. - Measurement results can be easily set as attribute values of solids and utilized for BOM creation. - It is possible to measure the entire assembly or only selected components. - In 2D, there are dimension calculation functions for springs, spline shafts, gears, and shafts. In addition to weight and volume calculation functions, VariCAD is equipped with various basic tools such as BOM creation, sheet metal unfolding, mechanical component calculation functions, and assembly functions, all at a low price starting from around 130,000 yen including tax with one year of support. Furthermore, for Ipros members who download the catalog, we are currently offering a 5,000 yen discount coupon. *Download the 30-day free trial version here: https://varicad.add-soft.jp/download/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features of 3D CAD VariCAD - It has an extensive rendering function, allowing for settings such as light positioning, smoothness of spheres, surface reflectivity, and perspective. - The rendered 3D view can be output in image file formats such as PNG or JPG. It can be easily incorporated into presentation software, enabling a more realistic conveyance of the product image to customers and business partners through the rendering function. In addition to the rendering function, VariCAD includes various basic tools such as BOM creation, sheet metal unfolding, calculations for mechanical parts, and assembly functions, all at a low price starting from around 130,000 yen including one year of support. Furthermore, for Ipros members who download the catalog, we are currently offering a discount coupon of 5,000 yen. *Download the 30-day free trial version here: https://varicad.add-soft.jp/download/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features of 3D CAD VariCAD - Easily create links between assembly part files and part files, allowing edits made in the part files to be reflected in the assembly part drawings. - If there are changes in the design, it can be updated to the latest state immediately, reducing work time. - In the assembly part files, it is easy to check for interference between parts. In addition to assembly functions, VariCAD includes various basic tools such as BOM creation, sheet metal unfolding, and mechanical component calculation functions, all available at a low price starting from around 130,000 yen including one year of support. Furthermore, Ipros members who download the catalog can receive a discount coupon of 5,000 yen. *Download the 30-day free trial version here: https://varicad.add-soft.jp/download/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Features of VariCAD, a 3D CAD software: - Easily create 2D cross-sectional views and isometric views from 3D data. With VariCAD, patent drawings can be created effortlessly. - Export created solids as STEP or STL format files in the state of cross-sectional data. - It is also possible to directly output PNG or JPG image format files from VariCAD using 3D data, which is very convenient when sending image files to clients. In addition to the cross-sectional and isometric view creation features, VariCAD includes various basic tools such as BOM creation, sheet metal unfolding, and calculations for mechanical parts, all at a low price starting from around 130,000 yen including one year of support. Furthermore, for Ipros members who download the catalog, we are currently offering a discount coupon of 5,000 yen.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

- VariCAD, the 3D CAD software, manages the composition of each part in a tree-structured hierarchy that is easy to understand at a glance. - Registering new materials, adding information about parts, and setting solid attributes is simple! - With VariCAD, you can grasp the total number of parts required for a product using 3D CAD drawing data, and link that information with part costs, making cost estimation work easy. - By utilizing BOM, you can prevent missing part orders, share material lists with other users, and achieve smooth part management. In addition to the BOM function, VariCAD includes various basic tools such as batch conversion from 3D to 2D drawings, creation of sheet metal unfolding drawings, and calculation functions for mechanical parts, all at a low price starting from around 130,000 yen including one year of support. Furthermore, for Ipros members who download the catalog, we are currently offering a discount coupon of 5,000 yen. *Download the 30-day free trial version here: https://varicad.add-soft.jp/download/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Aren't you distinguishing between 3D CAD and 2D CAD? The differentiation between the two CAD software can be quite cumbersome and not light on cost. VariCAD solves the problems of such designers! VariCAD is a CAD software that supports both 3D and 2D, developed for mechanical design to assist in "manufacturing." It is equipped with the essential 3D and 2D basic tools needed for mechanical design, while being priced under 100,000 yen, thus reducing the cost burden of "manufacturing" with excellent cost performance. Unlike other CAD software, there is no need for additional installation of paid plugins. All the necessary functions for design are included, so there are no additional costs incurred. It has received very high praise from many companies struggling with design costs. Amidst rising prices of various products, VariCAD is firmly resisting price increases and maintains a price below 100,000 yen! Furthermore, we are offering a 5,000 yen discount coupon exclusively for Ipros members who download the catalog!

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Even when we talk about metal processing, there are various manufacturing methods such as casting, forging, die casting, and pressing, and in terms of processing, there are also various finishing methods like cutting, plating, and mirror finishing, resulting in a wide variety of finished states. However, regardless of the type of products being made, inspections are always necessary. For aspects that cannot be discerned visually, such as weight and conductivity, various measuring devices are likely used, but many still rely on visual inspections for appearance checks. Some may be considering automating inspections, but they might be unsure about how to proceed or whether their products can truly be inspected. For those individuals, how about trying our "iVision"? We confirm with our customers what they want to inspect and under what conditions, and we conduct preliminary validations to ensure that it can indeed be verified. Additionally, we have a wealth of experience in verification and implementation for numerous metal products, including those related to the automotive industry. If you think, "Our products are too difficult, so it's impossible," or "We were turned down by other companies," we encourage you to give it a try.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our "iVision" is offered with full customization to meet your needs. For each project, we will confirm the inspection target and the desired form of inspection equipment and provide appropriate solutions. We would like to introduce a collection of case studies that summarize our numerous achievements and proposals. In the case study collection, we provide illustrations and simple processing flows of our achievements and proposals, along with clear explanations. There may be examples that closely resemble what you are considering, ranging from large inspection equipment to inline installations, as well as inspections using AI and 3D sensors. Additionally, even if there are no entries in the case study collection, please feel free to contact us, and we will propose a style that meets your desires. If you have been dissatisfied with inspection equipment from other companies, please consider our "iVision."

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Would you like to switch the visual inspection of products lined up in the tray within the process from "manual inspection" to "automated inspection using a camera"? We will introduce a practical example of the "iVision Robot," which allows inspection for each cell by installing a camera and lighting on a general-purpose XY stage moving device. By using a two-dimensional operating stage, it becomes possible to inspect the workpieces lined up in the tray sequentially without having to set the camera position each time, allowing you to confirm which cell had what kind of defect. 【Features of this system】 - By using a two-dimensional operating stage, it is possible to inspect the tray by cell. - Displays a map showing where and what kind of defects were found in the tray. - The device can be modified based on the inspection content. *First, we will verify whether the workpieces you wish to inspect can be inspected. *Detailed processing information and flow are included in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Would you like to switch the measurement of the fine unevenness on the surface of metal plates from "manual measurement" to "automated inspection using a 3D sensor"? We will introduce examples of automating visual inspections conducted using a 3D sensor. By using a 3D sensor, it becomes possible to check the condition of the surface of metal plates. Utilizing the 3D sensor allows for the inspection of the fine unevenness of metal products, enabling efficient polishing and warping correction of metal products. 【Features of this system】 - By using a 3D sensor, it is possible to measure not only the size of the unevenness but also the depth direction. - By pre-registering reference values and tolerances, it is possible to quickly determine OK or NG. *First, we will verify whether the work that the customer wishes to inspect is feasible. *Detailed processing information, including details and processing flow, is provided in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Regarding the inspection of discoloration (such as rot) of vegetables being transported on the line, would you consider switching from "visual inspection" to "automated inspection using cameras"? By installing cameras and lighting on the existing transport line and utilizing AI, we can create a system to inspect whether any rotting vegetables are flowing through during transportation. For irregularly shaped items, such as certain vegetables that are difficult to distinguish with conventional inspection devices, it becomes possible to identify them using AI. 【Features of this system】 - Inspection can be conducted on the transport line without creating a separate inspection system. - Since inspections are performed on the transport line, it is possible to conduct inspections without the need for additional equipment. - AI enables inspections for irregularly shaped vegetables. - The equipment can be modified based on the inspection requirements. *First, we will verify whether the work you wish to inspect is feasible. *Detailed processing information and flow are provided in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Regarding the comprehensive inspection of products with complex shapes, such as scratches, dents, and residual cutting chips, would you consider switching from "visual inspection" to "automated inspection using cameras"? We would like to introduce a case study of an inspection device that uses a multi-axis robot equipped with a camera and lighting to inspect components with complex shapes. In this system, by attaching a camera and lighting to a multi-axis robot, we can inspect components that are difficult to examine with a fixed camera, capturing images of defective areas sequentially, similar to human inspection. By using a robot, we can direct the camera and lighting to various locations on components of different shapes, making it possible to handle parts with complex geometries that traditional automated inspections struggle with. 【Features of this system】 ■ Automated inspection system using multi-axis robots ■ Capable of specifying and inspecting various locations on complex shapes ■ Able to accommodate heavy or large items by moving the camera ■ The inspection setup can be modified based on the inspection requirements *First, we will verify whether the workpieces you wish to inspect can be accommodated. *Detailed processing information and flow are provided in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Regarding the inspection of foreign objects and black spots in resin molded products, why not switch from "visual inspection" to "automated inspection using cameras"? We would like to introduce a case study of an inspection device equipped with a mechanism for separating and discharging OK and NG items, created with a separate transport system. In this system, a separate transport line is created, where items are manually fed in, and inspection is conducted using a camera installed on the line. The inspection device has a mechanism to change the discharge destination based on the inspection results, allowing for the identification and separation of defects such as foreign objects and black spots in resin molded products. By making the feeding part manual, it becomes possible to automate the process at a relatively low cost compared to inspection devices that use parts feeders. 【Features of this system】 ■ Automated inspection system with a separately created transport line ■ Improved work efficiency by separating items based on conditions during discharge ■ Reduction of system costs by performing manual feeding ■ The device can be modified based on inspection requirements *First, we will verify whether the work you wish to inspect is feasible. *Detailed processing information and flow are included in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Would you like to switch the inspection of surface scratches, dents, and foreign objects on long items such as pipes and steel materials from "visual inspection" to "automated inspection using cameras"? We would like to introduce a case study of a hand-held inspection device that uses multiple cameras and lighting for the appearance inspection of long items, which cannot be captured by a single camera. This system is a hand-held inspection device that installs multiple cameras and lighting on an inspection stand, allowing for the assessment of scratches, dents, and foreign object adhesion on the surface of long workpieces. By analyzing images captured by multiple cameras simultaneously, there is no need to move the workpiece sequentially under the camera, and inspections can be performed in a short time. 【Features of this system】 - A simple inspection system that does not require a moving device, with multiple cameras and lighting installed on the inspection stand. - Capable of inspecting objects that are too long to be captured by a single camera in one go. - The device can be modified based on the inspection requirements. *First, we will verify whether the workpieces you wish to inspect can be inspected. *Detailed processing information and flow are provided in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Would you like to switch from "visual inspection" to "automated inspection using cameras" for inspecting and monitoring scratches and foreign objects on molds used for shaping resin and metal? We would like to introduce a case study of a hand-held inspection device that installs molds at designated locations for shaping and other purposes. In this system, a hand-held inspection device is equipped only with a camera and lighting on the inspection stand, which determines the presence of scratches, foreign object contamination, and mold deterioration. By monitoring the condition of the mold, it becomes possible to detect defects caused by the mold during shaping in advance, thereby reducing the risk of mass production of defects. 【Features of this system】 ■ A simple inspection system with a camera and lighting installed on the inspection stand ■ Contributes to reducing defects during shaping by inspecting the molds ■ The device can be modified based on the inspection requirements *First, we will verify whether the work you wish to inspect can be accommodated. *Detailed processing information, including specifics and processing flow, is included in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Regarding the inspection of metal parts being transported on the line, including the mixing of different types and shape defects, would you consider switching from "visual inspection" to "automated inspection using cameras"? This system involves installing cameras and lighting on the existing transport line to inspect whether items that differ from pre-stored shapes are flowing through during transport. It is suitable for manufacturing processes that handle components with different detailed shapes on the left and right or components with differing hole positions. 【Features of this system】 - Inspection can be conducted on the transport line without creating a separate inspection system. - Conducting inspections on the transport line is effective in preventing outflow to the next process. - Effective for processes using components with subtle differences, such as differing hole positions. - The equipment can be modified based on the inspection requirements. *First, we will verify whether the workpieces you wish to inspect can be accommodated. *Detailed processing information, including the processing flow, is provided in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Regarding the inspection of surface scratches and dents on metal plates being transported on the line, would you consider switching from "visual inspection" to "automated inspection using cameras"? This system will involve installing cameras and lighting on the existing transport line to inspect various defects on the surface of the metal plates during transportation. By conducting inspections on the existing transport line for components like metal plates, which are difficult to handle manually, it becomes possible to reduce the effort and human errors associated with separate inspections. 【Features of this system】 - Inspections can be conducted on the transport line without creating a separate inspection system. - Since inspections are performed on the transport line, quick responses can be made in case of defects. - Inspections are carried out by considering the surface conditions and using appropriate cameras and lighting. - The equipment can be modified based on the inspection content. *First, we will verify whether the work you wish to inspect is feasible. *Detailed processing information and flow are included in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Regarding the confirmation of the printing state of labels output from the label printer, such as printing content, smudging, and blurring, would you consider switching from "visual inspection" to "automated inspection using a camera"? We would like to introduce a system that installs a camera and lighting between the labels output from the printer and the winding mechanism to capture images and conduct inspections. In this system, for the labels printed by the printer, we first teach the system the state of a good label and then perform comparisons to inspect various printing defects all at once. Additionally, it is also possible to verify whether the correct values and information are recorded for lot numbers and barcodes. 【Features of this system】 - By conducting inspections immediately after printing, it allows for quick responses to issues with the printing device. - By recording the image of a good label initially, it can accommodate various types of labels. - It simultaneously checks not only printing defects but also the content of printed information such as lot numbers. *First, we will verify whether the work desired by the customer can be inspected. *Detailed processing information and flow are included in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Shall we switch from "manual measurement" of the warping and unevenness of metal plates to "automatic inspection using a 3D sensor"? We will introduce a practical example of the "iVision Robot," which enables measurement by installing a 3D sensor on a general-purpose XY stage moving device. By using a two-dimensional operating stage, it becomes possible to check the condition of the metal plate's surface. Utilizing the 3D sensor allows for the inspection of the unevenness and warping of metal products, enabling efficient polishing and warping correction of metal products. 【Features of this system】 ■ By operating the stage and 3D sensor, measurement of the entire surface of metal plates of a certain size is possible. ■ The use of a 3D sensor allows for measurement not only of the size of unevenness but also in the depth direction. ■ By registering standard values and tolerances in advance, rapid determination of OK or NG can be performed. *First, we will verify whether the work you wish to inspect can be measured. *Detailed processing information and flow are provided in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Would you consider switching from "visual inspection" to "automated inspection using cameras" for the bottle's "black spots, scratches, dirt, and printing defects"? We would like to introduce a case where a dedicated inspection device was created to implement a system that conducts these inspections all at once. In this system, when a workpiece is fed into the product input section, it is sent out one by one, and inspections are performed on various parts of the resin bottle, including the outer circumference and nozzle section, using multiple cameras and rotating fixtures. By using imaging environments suited to each specific area, it becomes possible to accurately confirm defects in the areas that need detection. 【Features of this system】 ■ Creation and operation of a dedicated inspection device that performs complex operations ■ Ability to conduct various inspections simultaneously by installing cameras in appropriate locations ■ Recording of which inspection items have defects ■ The device can be modified based on the inspection content *First, we will verify whether the workpieces you wish to inspect can be inspected. *Detailed processing information and flow are provided in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Shall we switch from "manual measurement" of the outer diameter and internal dimensions of resin molded products to "automatic inspection using a camera"? We would like to introduce a practical example of the "iVision Robot," which enables dimension measurement by installing a camera on a general-purpose XY stage moving device. By using a two-dimensional operating stage, it becomes possible to check the entire mounting state of the substrate, which cannot be confirmed with a single camera. 【Features of this system】 - It is possible to measure a wide range of dimensions that cannot be captured by a single camera through the operation of multiple cameras. - For multiple dimension inspections, measurements can be conducted in one inspection by setting the measurement points. - It is also possible to determine whether the measurements are within tolerance based on information such as drawings. *First, we will verify whether the work you wish to inspect can be measured. *Detailed processing information and flow are provided in the PDF.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration