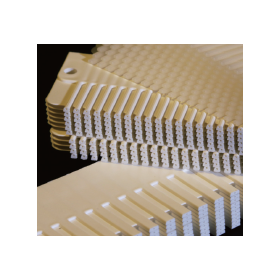

Thermal conduction molded products

Heat dissipation performance closer to metal materials than general-purpose resins! Proposing material and product design tailored to the quality requirements of various products.

At Sekisui Techno Molding, we handle "thermal conductive molded products." These molded products excel in the balance of impact resistance, lightweight, and thermal conductivity, offering heat dissipation performance closer to that of metal materials than general-purpose resins. Grades with low volume resistivity can be applied for EMC measures. We propose material and product designs tailored to the quality requirements of various products. Please feel free to contact us when you need assistance. 【Features】 ■ Achieves high heat dissipation and high impact resistance through unique material formulation technology ■ High lightweight effect achieved by resinizing metals ■ Product designs that leverage freedom of shape ■ Molded products with an excellent balance of impact resistance, lightweight, and thermal conductivity ■ Grades with low volume resistivity can be applied for EMC measures * For more details, please refer to the PDF materials or feel free to contact us.

- Company:積水テクノ成型 新事業開発部

- Price:Other