1~45 item / All 48 items

Displayed results

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Contact this company

Contact Us OnlineBefore making an inquiry

Download PDF1~45 item / All 48 items

The focused ion beam (FIB) device irradiates a focused ion beam onto a sample for processing and observation. Additionally, the FIB-SEM is equipped with a high-resolution FE-SEM (field emission scanning electron microscope), which allows for simultaneous high-resolution observation and processing. This video demonstrates the observation of "plating defects" using the Slice & View and 3D construction functions of the FIB-SEM (Thermo Fisher Scientific: Helios5 CX). For more details, please watch the video.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Temperature-modulated DSC provides a wealth of information that cannot be obtained with conventional DSC, enabling the following: - Distinction of thermal history, etc., through comparison of reversible and irreversible components as mentioned above. - Measurement of specific heat in high-temperature regions above around 1000°C, which is considered difficult with the JIS method. - Measurement of specific heat in low-temperature regions below room temperature. Additionally, it is expected to be useful for analyzing relaxation phenomena. In this case, as an example of that technology, we introduce "a case study evaluating PET." For more details, please refer to the PDF materials. Furthermore, in addition to DSC, our company also specializes in various thermal analyses such as TG-DTA and TMA. ● DSC (Differential Scanning Calorimetry): Can be used for analysis of sample melting, glass transition, thermal history, crystallization, curing, Curie point, etc., and for measuring specific heat. ● TG-DTA (Thermogravimetric and Differential Thermal Analysis): Can be used for analysis of sample moisture content, ash content, decomposition, oxidation, and heat resistance evaluation. ● TMA (Thermomechanical Analysis): Can be used for measuring sample expansion rate, glass transition, softening point, etc. For more information, visit here: https://www.seiko-sfc.co.jp/analysis-service/thermal-analysis.html

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company uses a simultaneous thermogravimetric and differential thermal analysis device (TG-DTA) to appropriately select the atmosphere and clarify the weight measurement and component ratios of organic and inorganic materials. In this case, we introduce an example of that technology: "Quantification of carbon black in rubber." This measurement allows us to understand the component ratios of natural rubber, carbon black, and inorganic/metal components in rubber. For more details, please refer to the PDF materials. In addition to TG-DTA, our company also specializes in various thermal analyses such as DSC and TMA. https://www.seiko-sfc.co.jp/service/thermal.html ●DSC (Differential Scanning Calorimetry): It can be used for analyzing sample melting, glass transition, thermal history, crystallization, curing, Curie point, etc., as well as measuring specific heat. ●TG-DTA (Thermogravimetric and Differential Thermal Analysis): It can be used for analyzing moisture content, ash content, decomposition, oxidation, and evaluating heat resistance of samples. ●TMA (Thermomechanical Analysis): It can be used for measuring sample expansion rate, glass transition, softening point, etc. Please see below for other examples. https://www.seiko-sfc.co.jp/analysis-service/case.html

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The FIB (Focused Ion Beam) system allows for maskless etching processing to create arbitrary shapes. In this case, we introduce the fabrication of pillars at 50nm steps with the following sizes: - Circular: φ5μm - Pillar height: 700nm/650nm/600nm - Pillar diameter: φ500nm Please take a moment to read the PDF materials. Additionally, our company specializes in wiring modifications aimed at circuit corrections for ICs and LSIs using FIB. Specifically, we offer the following services: - Cutting of wiring - Connecting of wiring - Fabrication of test pads for characteristic evaluation We perform these services with a short turnaround time to assist in your IC and LSI development. We would be happy to discuss this further, so please feel free to reach out. *If you need more details, please do not hesitate to contact us. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

At our company, by applying the WLF rule (the time-temperature superposition principle) to the results of DMA measurements, we can estimate properties such as elasticity in frequency regions that have not actually been measured (creating master curves). Would you like to utilize this technology to understand material properties? In this case, we introduce an example of this technology: "Prediction of long-term deformation of rubber (creep test)". Please refer to the PDF document for details. In addition to DSC, our company also specializes in various thermal analyses such as TG-DTA and TMA. https://www.seiko-sfc.co.jp/service/thermal.html ●DSC (Differential Scanning Calorimetry): Used for analyzing melting, glass transition, thermal history, crystallization, curing, Curie point, etc., and for measuring specific heat. ●TG-DTA (Thermogravimetric and Differential Thermal Analysis): Used for analyzing moisture content, ash content, decomposition, oxidation, and evaluating heat resistance. ●TMA (Thermomechanical Analysis): Used for measuring expansion rate, glass transition, softening point, etc. Please see below for other examples as well. https://www.seiko-sfc.co.jp/case/index.html

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

AFM scanning probe microscopy is a device that detects various physical interactions occurring between a probe and the sample surface, allowing for the observation of surface morphology in small areas and the measurement of electrical and mechanical properties. These physical interactions include atomic force, frictional force, and electrostatic force. It can perform measurements in various environments, including atmospheric and vacuum conditions, and is capable of observing sample surfaces regardless of whether they are conductive or insulating. Additionally, by using a cryo-microtome, it is possible to produce ultra-thin sections of soft polymer materials such as resins under frozen conditions. We are observing polyisoprene rubber from various angles using this AFM and cryo-microtome. Please take a moment to read the PDF materials. This technology can be applied not only to rubber but also to resins, plastics, and various polymer materials. Furthermore, our company conducts various surface analyses, including XPS, AES, and GD-OES, in addition to this analytical device. We would be happy to assist you, so please feel free to reach out. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/ *Other materials are also available. If you request through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In starch processed foods, it is very important to understand the gelatinization (α phase) and the retrogradation (β phase) phenomena. Our company has the technology to grasp these phenomena using DSC (Differential Scanning Calorimetry). In this case, we introduce an example of this technology: "Understanding the gelatinization of starch in rice and noodles." Additionally, this technology can also measure the degree of retrogradation. For more details, please refer to the PDF materials. In addition to DSC, our company also specializes in various thermal analyses such as TG-DTA and TMA. https://www.seiko-sfc.co.jp/service/thermal.html ●DSC (Differential Scanning Calorimetry): It can be used for analyzing sample melting, glass transition, thermal history, crystallization, curing, Curie point, etc., as well as measuring specific heat. ●TG-DTA (Thermogravimetric and Differential Thermal Analysis): It can be used for analyzing moisture content, ash content, decomposition, oxidation, and evaluating heat resistance. ●TMA (Thermomechanical Analysis): It can be used for measuring sample expansion rate, glass transition, softening point, etc. There are other examples available, so please take a look. https://www.seiko-sfc.co.jp/case/index.html

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Electron Backscatter Diffraction Pattern (EBSD) allows for the understanding of the crystal orientation distribution of materials when combined with a Scanning Electron Microscope (SEM). This case introduces "EBSD measurement of samarium cobalt magnets." Many customers are utilizing this technology for performance evaluation and improvement of various magnets. Please take a look at the PDF materials. In addition to EBSD and SEM, our company also conducts various cross-sectional analyses using TEM and surface analysis using XPS, providing multifaceted analytical services. Both sales and technical staff are available for direct assistance, so we would be grateful if you could feel free to consult with us. Seiko Future Creation Official Website: https://www.seiko-sfc.co.jp/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Electron Backscatter Diffraction Pattern (EBSD) can be combined with Scanning Electron Microscopy (SEM) to enable the following: ● Measurement of the shape and orientation of micro-regions of crystal grains ● Confirmation of the orientation of crystals relative to a reference orientation ● Measurement of internal strain in materials from information on crystal orientation differences In this case, we introduce "Evaluation of Aluminum Sputter Films Using EBSD." This measurement technique is useful for evaluating the performance of aluminum sputter films and for substrate selection. It can also be applied to ceramic materials if there is orientation evaluation and crystallinity. We encourage you to give it a try. In addition to EBSD and SEM, our company also conducts various cross-sectional analyses using TEM and surface analysis using XPS, allowing for multifaceted analytical evaluations. Both sales and technical staff are available to assist directly, so we would appreciate it if you could feel free to consult with us. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Electron Backscatter Diffraction Pattern (EBSD) allows for the following when combined with a Scanning Electron Microscope (SEM): - Analysis of crystal orientation after cross-section formation - Confirmation of shape changes in metal microstructures and internal strain distribution In this case, we introduce "internal strain measurement of wire materials" using EBSD. This measurement technique is useful for determining whether bending processes, such as those for leaf springs and hair springs, are appropriate and for setting processing conditions. We encourage you to give it a try. Additionally, our company conducts various cross-sectional analyses using TEM and surface analysis using XPS, enabling multifaceted analytical evaluations. Both sales and technical staff are available to assist directly, so we would be grateful if you could feel free to consult with us. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Electron Backscatter Diffraction Pattern (EBSD) allows for the following when combined with a Scanning Electron Microscope (SEM): - Separation of phases with different crystal systems - Distribution ratio and crystal orientation analysis for each separated phase In this case, we introduce "metal microstructure observation of wire (spring material) using EBSD." We investigated the changes in metal microstructure during the processing of spring material (drawing with a diameter of Φ1.00mm and 0.07mm) and confirmed that the metal microstructure changes after drawing. This measurement technique is very useful for selecting metal materials and comparing during material changes. We encourage you to give it a try. Additionally, our company conducts various cross-sectional analyses using TEM and surface analysis using XPS, allowing for multifaceted analytical assessments. Both sales and technical staff are available to assist directly, so please feel free to consult with us. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We will conduct the on-site analysis usually performed during regular visits online using web conferencing tools. - We will share data images from the analysis equipment on the web conferencing tool. - We will provide explanations of the analysis content from our company, exchange information between our company and the customer, and conduct Q&A in real-time via communication. - This can be done using FIB, TEM, and AFM. Please consult us about other analysis equipment as well. We would be happy to discuss on-site analysis with you. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/ *We have many analysis case studies available. If you request through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Electron Backscatter Diffraction Pattern (EBSD) allows for the following when combined with a Scanning Electron Microscope (SEM): - Separation of phases with different crystal systems - Distribution ratio and crystal orientation analysis for each separated phase In this case, we introduce phase analysis of a two-phase stainless steel using EBSD. With EBSD, the distribution ratio and crystal orientation of the α phase and γ phase in the two-phase stainless steel were confirmed. This measurement technique can be utilized to compare properties such as hardness and brittleness in the distribution of materials in metals and metal compounds, as well as to detect the degree of precipitation and understand its impact on color. We encourage you to give it a try. Additionally, our company conducts various cross-sectional analyses using TEM and surface analysis using XPS, allowing for multifaceted analytical assessments. Our engineers are available to assist directly, so please feel free to consult with us. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The Electron Backscatter Diffraction Pattern (EBSD) method, when combined with a scanning electron microscope (SEM), enables the following: - Analysis of crystal grain size and phase structure in micro-regions - Evaluation of residual stress in small areas such as mounting parts (with analysis examples at approximately 50μm) This case introduces the measurement of internal strain in solder cross-sections using EBSD. Changes in "internal strain of solder due to thermal shock testing" were confirmed with EBSD. This measurement technique can be applied to predict potential defects arising from variations in solder conditions or aging degradation. We encourage you to give it a try. Additionally, our company conducts various cross-sectional analyses using TEM in conjunction with EBSD and SEM. We would be happy to assist you, so please feel free to reach out. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/ *We have many other materials available. If you request through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In STEM (Scanning Transmission Electron Microscopy) and EDS (Energy Dispersive X-ray Spectroscopy), information regarding the composition of the sample (contrast images reflecting atomic numbers) can be obtained by scanning a finely focused electron beam over the sample. Additionally, the following features are available: - Observation of changes in diffraction contrast by varying the angle of incidence of the electron beam - Determination of whether the observation target is crystalline - Acquisition of information on crystal defects (dislocations, twins, etc.) within the crystal In this case, we introduce "Evaluation of Semiconductor Insulating Films using STEM-EDS." This case yielded no issues, but abnormal detection is also possible. Please take a moment to read the PDF materials. Furthermore, in addition to this STEM, our company excels in identifying defective areas by performing 3D reconstruction on specific regions of the sample in combination with FIB. We would be happy to provide a demonstration, so please feel free to reach out to us. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/ *Other materials are also available. If you request them through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In STEM (Scanning Transmission Electron Microscopy) and EDS (Energy Dispersive X-ray Spectroscopy), information about the composition of the sample (contrast images reflecting atomic numbers) can be obtained by scanning a finely focused electron beam over the sample. The following features are also available: - Observation of changes in diffraction contrast by varying the angle of incidence of the electron beam - Determination of whether the observation target is crystalline - Acquisition of information about crystal defects (dislocations, twins, etc.) within the crystal In this case, we will introduce "Failure Analysis of Au-Plated Connector Terminal Contacts Using STEM." Please take a moment to read the PDF materials. Additionally, our company conducts various cross-sectional analyses using not only STEM but also TEM and SEM. We would be happy to assist you, so please feel free to reach out. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/ *Other materials are also available. If you request them through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The differential thermal gravimetric analysis device (TG/DTA) allows for the measurement of weight changes due to oxidation, thermal decomposition, dehydration, etc., as well as the evaluation of thermal resistance and analysis of reaction rates. In this case, we will introduce "the influence of atmosphere in TG-DTA measurements." We listen to our customers' situations and propose appropriate measurement atmospheres, which serves as the background for this. By utilizing this comparison, it is possible to distinguish whether the resin sample itself is burning or if it is gas released from the sample. In addition to TG/DTA, our company also specializes in various thermal analyses such as DSC and TMA. ●DSC: It can be used for the analysis of melting, glass transition, thermal history, crystallization, curing, Curie point, etc., as well as for measuring specific heat. ●TMA: It can be used for measuring expansion rates, glass transition, softening points, etc. Please see the following for examples of thermal analysis: https://www.seiko-sfc.co.jp/case/index.html *Other materials are also available. If you request through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The differential thermal gravimetric analysis device (TG/DTA) allows for the measurement of weight changes due to oxidation, thermal decomposition, dehydration, etc., as well as the evaluation of thermal resistance and analysis of reaction rates. In this case, we will introduce "the influence of atmosphere in TG-DTA measurements." We listen to our customers' situations and propose appropriate measurement atmospheres, which serves as the background for this. By utilizing this comparison, it is possible to distinguish whether the resin sample itself is burning or if it is gas released from the sample. In addition to TG/DTA, our company also specializes in various thermal analyses such as DSC and TMA. ●DSC: It can be used for the analysis of sample melting, glass transition, thermal history, crystallization, curing, Curie point, etc., as well as for measuring specific heat. ●TMA: It can be used for measuring sample expansion rates, glass transition, softening points, etc. Please see the following for examples of thermal analysis: https://www.seiko-sfc.co.jp/case/index.html *Other materials are also available. If you request them through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Glow Discharge Optical Emission Spectrometry (GD-OES) is a method for analyzing the composition of a sample by sputtering atoms from the surface of the sample, exciting those atoms into a plasma state, and measuring the resulting emission. One of the features of this device is its ability to detect hydrogen (H). In this case, we will introduce the "composition investigation of discolored stainless steel (SUS)." Please take a moment to read the PDF materials. Additionally, our company conducts various surface analyses, including XPS and AES Auger, in addition to GD-OES. We would be happy to assist you, so please feel free to reach out. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/ *Other materials are also available. If you request through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The AFM scanning probe microscope is a device that "detects various physical interactions between the probe and the sample surface, allowing for the observation of surface shapes in minute areas and the measurement of electrical and mechanical properties." These physical interactions include atomic forces, frictional forces, and electrostatic forces. Additionally, measurements can be taken in various environments, including atmospheric and vacuum conditions, enabling the observation of sample surfaces regardless of conductivity or insulation. Using this analytical device, we conducted an investigation into the "surface treatment of plated connector contact parts." Please take a moment to read the PDF materials. Furthermore, in addition to this analytical device, our company also conducts various surface analyses such as XPS, AES, and GD-OES. We would be happy to assist you, so please feel free to reach out. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/ *We have many other achievements as well. If you request through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

X-ray photoelectron spectroscopy (XPS) can obtain elemental information from the very surface of a sample (a few nm), making it effective for evaluating surface treatments and analyzing surface contamination and discoloration. It is capable not only of identifying elements but also of analyzing the bonding states of those elements. In this case, we will introduce the "investigation of discoloration on a material surface (nickel plating) using XPS." We explored the reasons for discoloration, which is a defect in nickel plating, through surface analysis with XPS. Please take a moment to read the PDF materials. Additionally, our company conducts various surface analyses, including GD-OES and Auger spectroscopy, in addition to XPS. We would be happy to assist you, so please feel free to reach out. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/ *Other materials are also available. If you request them through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Depending on the material, glass transition, cryocrystallization, and melting points may exist in the low-temperature range. Our company has the technology to measure these characteristics using DSC (Differential Scanning Calorimetry). We hope you can utilize this technology to understand material properties. In this case, we introduce an example of this technology: "DSC Measurement of Silicone Rubber (Low-Temperature Measurement)." Please refer to the PDF document for details. In addition to DSC, our company also specializes in various thermal analyses such as TG-DTA and TMA. https://www.seiko-sfc.co.jp/service/thermal.html ●DSC (Differential Scanning Calorimetry): Can be used for analysis of sample melting, glass transition, thermal history, crystallization, curing, Curie point, etc., as well as measuring specific heat. ●TG-DTA (Thermogravimetric and Differential Thermal Analysis): Can be used for analysis of sample moisture content, ash content, decomposition, oxidation, and thermal resistance evaluation. ●TMA (Thermomechanical Analysis): Can be used for measuring sample expansion rate, glass transition, softening point, etc. Please take a look at many other examples below: https://www.seiko-sfc.co.jp/case/index.html

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

We obtained XPS narrow spectra and analyzed the states of the C1s spectra, which allowed us to determine the types of carbon bonds and their quantitative values. By combining this with contact angle measurements, it can be utilized for evaluating hydrophobicity and hydrophilicity. In this case, we will introduce "Analysis of Hydrophobic Films by XPS." Please take a moment to read the PDF materials. Additionally, our company conducts various surface analyses, including GD-OES and Auger, in addition to XPS. We would be happy to assist you, so please feel free to reach out. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/ *Other materials are also available. If you request them through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The AFM scanning probe microscope is a device that detects various physical interactions occurring between the probe and the sample surface, allowing for the observation of surface shapes in minute areas and the measurement of electrical and mechanical properties. These physical interactions include atomic forces, frictional forces, and electrostatic forces. Additionally, measurements can be conducted in various environments, including atmospheric and vacuum conditions, enabling the observation of sample surfaces regardless of whether they are conductive or insulating. The AES Auger electron spectrometer allows for elemental analysis of the extreme surface layer of materials (approximately 5nm) and investigation of concentration gradients in the depth direction. Using these two analytical devices, we conducted a study on the heating effects on the surface of plated connector contact pins. Please take a moment to read the PDF materials. Furthermore, in addition to these analytical devices, our company also conducts various surface analyses such as XPS and GD-OES. We would be happy to assist you, so please feel free to reach out to us. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/ *Other materials are also available. If you request through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Differential Scanning Calorimetry (DSC) can be used to analyze the melting, glass transition, thermal history, crystallization, curing, Curie point, and to measure specific heat of samples. By measuring melting behavior, it is possible to assess differences in thermal history within the same sample. Using DSC to measure melting behavior allows for an understanding of the relationship between thermal history and crystal form, which can be applied to the examination of manufacturing conditions and quality control. In this case, we introduce an analysis of chocolate, a familiar item for everyone, using DSC. This is the fourth installment, "DSC Measurement of Chocolate 4 (Verification of Optimal Production Conditions)." It reveals important aspects of the chocolate tempering process (the work of aligning cocoa butter to the V-type crystal among the six types of crystal forms). We encourage you to read the PDF document. In addition to DSC, our company also specializes in various thermal analyses such as TG/DTA and TMA. We have experience with other food products as well, so please feel free to consult us regarding thermal analysis. *Other materials are also available. If you request them through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Differential Scanning Calorimetry (DSC) can be used to analyze the melting, glass transition, thermal history, crystallization, curing, Curie point, and to measure specific heat of samples. By measuring the melting behavior, it is possible to assess differences in thermal history within the same sample. We are conducting analyses of chocolate, a familiar item to everyone. This case is the third installment, "DSC Measurement of Chocolate 2 (Comparison Between Products)." You can confirm the differences in melting between the center and the outer edge of the chocolate bar, so please take a moment to read the PDF materials. In addition to DSC, our company also specializes in various thermal analyses such as TG/DTA and TMA. ● TG/DTA: Can be used for analyzing moisture content, ash content, decomposition, oxidation, and evaluating heat resistance. ● TMA: Can be used for measuring expansion rate, glass transition, and softening point. We also have experience with other food products, so please feel free to consult us. ● Case Studies https://www.seiko-sfc.co.jp/case/index.html *Other materials are also available. If you request them through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Differential Scanning Calorimetry (DSC) can be used for analyzing the melting, glass transition, thermal history, crystallization, curing, Curie point, and measuring specific heat of samples. In this case, we introduce an analysis of familiar chocolate using DSC in "DSC Measurement of Chocolate 2 (Comparison Between Products)." This is the second installment. It is also useful for product comparison in determining the texture (melting) of chocolate, so please take a moment to read the PDF materials. In addition to DSC, our company specializes in various thermal analyses such as TG/DTA and TMA. ● TG/DTA: Can be used for analyzing moisture content, ash content, decomposition, oxidation, and evaluating heat resistance. ● TMA: Can be used for measuring expansion rate, glass transition, and softening point of samples. We also have experience with other food products, so please feel free to consult us regarding thermal analysis. Case Introduction https://www.seiko-sfc.co.jp/case/index.html *Other materials are also available. If you request through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Differential Scanning Calorimetry (DSC) can be used for the analysis of sample melting, glass transition, thermal history, crystallization, curing, Curie point, and the measurement of specific heat. In this case, we introduce an analysis of chocolate, which is familiar to everyone, through "DSC Measurement of Chocolate 1 (Estimation of Crystal Type)." It is useful for distinguishing the texture (melt-in-mouth) of chocolate and for quality control, so please take a moment to read the PDF materials. In addition to DSC, our company also specializes in various thermal analyses such as TG/DTA and TMA. ● TG/DTA: Can be used for analyzing moisture content, ash content, decomposition, oxidation, and heat resistance evaluation. ● TMA: Can be used for measuring sample expansion rate, glass transition, and softening point. We also have a track record with other food products, so please feel free to consult us regarding thermal analysis. Case introduction https://www.seiko-sfc.co.jp/case/index.html *Other materials are also available. If you request through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

A defect occurred where the surface of the polyimide film became hydrophobic, but due to the depth of information obtained from SEM/EDX analysis, the specific elements present on the very surface could not be detected. Therefore, we conducted surface analysis using X-ray photoelectron spectroscopy (XPS), which is a surface-sensitive method. In this case, we will introduce "Surface Contamination Analysis of Polyimide by XPS." Please take a moment to read the PDF materials. Additionally, our company conducts various surface analyses including GD-OES and Auger, in addition to this WPS. We would be happy to assist you, so please feel free to reach out. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/ *Other materials are also available. If you request through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Glow Discharge Optical Emission Spectrometry (GD-OES) is a method for analyzing the composition of a sample by sputtering atoms from its surface, exciting those atoms into a plasma state, and measuring the resulting emission. In this case, we will introduce the "investigation of substrate cleaning effects before the plating process" using GD-OES. Please take a moment to read the PDF materials. In addition to this case, our company has numerous analytical achievements related to plating. We also conduct various surface analyses, including XPS and Auger, in addition to GD-OES. If you have any questions, please feel free to consult with us. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/ *Other materials are also available. If you request through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

●Sample: Estimation of deformation and fracture due to localized compressive stress on plastic washers, gaskets, etc. ●Method: Compression creep measurement and stress-strain measurement using TMA (Thermomechanical Analysis) and stress-strain measurement equipment. ●Results: The deformation of the sample due to compression was understood from the creep curve and stress-strain curve. Please take a moment to read the PDF materials. In addition to TMA, our company also specializes in various thermal analyses such as DSC and TG/DTA. ●DSC: Can be used for analysis of sample melting, glass transition, thermal history, crystallization, curing, Curie point, etc., as well as measuring specific heat. ●TG/DTA: Can be used for analysis of moisture content, ash content, decomposition, oxidation, and evaluation of heat resistance. ●TMA: Can be used for measuring sample expansion rate, glass transition, softening point, etc. We would be happy to discuss this case and thermal analysis with you at any time. https://www.seiko-sfc.co.jp/service/thermal.html Case introduction https://www.seiko-sfc.co.jp/case/index.html *Other materials are also available. Please request them through the inquiry button, and we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

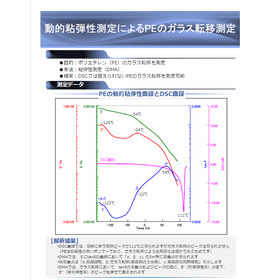

●Objective: Measurement of the glass transition of polyethylene (PE) ●Method: Dynamic Mechanical Analysis (DMA) ●Results: Measurement of the glass transition of PE, which cannot be captured by DSC In this case, we will introduce "Measurement of the glass transition of polyethylene (PE) using dynamic mechanical analysis (DMA)." Please take a moment to read the PDF materials. Our company also specializes in various thermal analyses including DSC, TG/DTA, and TMA. ●DSC: Can be used for analysis of sample melting, glass transition, thermal history, crystallization, curing, Curie point, etc., as well as for measuring specific heat. ●TG/DTA: Can be used for analysis of sample moisture content, ash content, decomposition, oxidation, and thermal resistance evaluation. ●TMA: Can be used for measuring sample expansion rate, glass transition, and softening point. We would be happy to assist you with any inquiries regarding thermal analysis. https://www.seiko-sfc.co.jp/service/thermal.html Case Studies https://www.seiko-sfc.co.jp/case/index.html *Other materials are also available. Please request them via the inquiry button, and we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In semiconductor packaging, it is important to understand the curing time of epoxy resin. The Kamal model is widely used as the reaction rate equation for the curing of epoxy resin. The coefficients of the Kamal model can be determined from the non-isothermal curing behavior measured by DSC (Differential Scanning Calorimetry). In this case, we will introduce "Analysis of Curing Characteristics of Epoxy Resin by Thermal Analysis using DSC." Please take a moment to read the PDF materials. In addition to DSC, our company also specializes in various thermal analyses such as TG/DTA and TMA. ● DSC: It can be used for analyzing sample melting, glass transition, thermal history, crystallization, curing, Curie point, and measuring specific heat. ● TG/DTA: It can be used for analyzing moisture content, ash content, decomposition, oxidation, and evaluating thermal resistance. ● TMA: It can be used for measuring sample expansion rate, glass transition, and softening point. Please see the following for various examples of thermal analysis: https://www.seiko-sfc.co.jp/case/index.html *Other materials are also available. If you request through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Our company's FIB (Focused Ion Beam) equipment can create cross-sections of objects approximately 0.1μm in size with precision. Using this technology, we can produce thin samples for TEM observation at exact locations. In this case, we introduce "Cross-section creation and observation of IC contact parts using FIB equipment." Please take a moment to read the PDF materials. Additionally, our company specializes in wiring modifications for ICs and LSIs using FIB. Specifically, we offer the following services: - Cutting of wiring - Connecting of wiring - Fabrication of test pads for characteristic evaluation We perform these tasks in a short turnaround time to assist our customers in their IC and LSI development. Furthermore, as a related technology to FIB, we have a case study on "Method for discovering abnormal areas within plating layers using FIB." We would be happy to discuss how you can utilize FIB equipment. *Please feel free to contact us if you need more details. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The FIB (Focused Ion Beam) device allows for maskless pattern drawing (pattern formation) of arbitrary shapes. - In pattern drawing through etching, it is possible to draw with a size of about 0.1μm per dot. (The minimum size varies depending on the material being processed and the processing conditions.) - Maskless ion implantation is also possible. - Pattern drawing through deposition is also feasible. In this case, we introduce how to actually draw patterns on a silicon substrate using the FIB device. Additionally, our company specializes in wiring modifications aimed at circuit corrections for ICs and LSIs using FIB. Specifically, we offer the following services: - Cutting of wiring - Connecting wiring - Fabrication of test pads for characteristic evaluation We carry out these tasks appropriately and in a short turnaround time to assist our customers in their IC and LSI development. We would be happy to assist you, so please feel free to consult with us. *If you need more details, please feel free to contact us. Seiko Future Creation Official Website https://www.seiko-sfc.co.jp/

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

The FIB (Focused Ion Beam) device can automatically create continuous cross-sections and obtain cross-sectional images. Using this function, it is possible to identify abnormal areas within a sample that are difficult to discern from the surface. In this case, we will introduce the method of discovering abnormal areas within a plating layer that cannot be detected from the surface using the continuous automatic cross-section production function of the FIB device. For more details, please refer to the PDF document or feel free to contact us. *Additionally, our company specializes in wiring modifications for ICs and LSIs using FIB for circuit corrections. Specifically, we offer the following services on a short turnaround: - Cutting of wiring - Connecting wiring - Fabrication of test pads for characteristic evaluation We are here to assist with your IC and LSI development, so please do not hesitate to consult with us. *We also have other materials available. If you request them through the inquiry button, we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In this case study collection, we will introduce examples related to "surface analysis." We feature numerous characteristics and analysis cases, including "investigation of discoloration on material surfaces using XPS," "evaluation of surface modification of PET using XPS," "analysis of hydrophobic films using XPS," and "evaluation of heating effects on plated parts." Additionally, we present analysis results, discoloration investigations, surface modification evaluations, and analyses of hydrophobic films. We encourage you to read through it. [Contents] ■ Investigation of discoloration on material surfaces using XPS ■ Evaluation of surface modification of PET using XPS ■ Analysis of hydrophobic films using XPS ■ Evaluation of heating effects on plated parts (AFM, AES) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In this case study collection, we will introduce examples related to "surface analysis." We cover the objectives, methods, and results of "cleaning evaluation of plating substrates (GD-OES measurement)," as well as the features and analysis cases of "surface contamination analysis using XPS," and the characteristics and analysis cases of "analysis of iron rust (Raman spectroscopy)," among many others. Additionally, we present analysis results, condition analysis, composition measurements, and more. We encourage you to read it. [Contents] ■ Cleaning evaluation of plating substrates (GD-OES measurement) ■ Surface contamination analysis using XPS ■ Condition analysis of copper oxide (XPS/AES analysis) ■ Analysis of iron rust (Raman spectroscopy) ■ Composition investigation of discolored stainless steel *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In this case study collection, we will introduce examples related to "thermal analysis." Starting with the analysis case of "curing property analysis of resins by thermal analysis," we will also cover the objectives, methods, and results of "high-resolution TG measurement methods (quasi-isothermal and quasi-isobaric weight measurement)," as well as the objectives, methods, and results of "glass transition measurement of PE by dynamic viscoelastic measurement." Additionally, we will present analysis results, measurement data, simulation results, and more. We encourage you to read through it. [Contents] ■ Curing property analysis of resins by thermal analysis ■ High-resolution TG measurement methods (quasi-isothermal and quasi-isobaric weight measurement) ■ Glass transition measurement of PE by dynamic viscoelastic measurement ■ Measurement of the firing process of clay using high-temperature TMA *Other cases are also available. Please contact us, and we will send them to you.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In this case study collection, we will introduce examples related to "thermal analysis." - "DSC Measurement of Silicone Rubber (Low-Temperature Measurement)" - "Quantification of Carbon Black by Thermogravimetric Measurement" - "Estimation of Deformation and Fracture of Plastics under Compressive Stress" We also present various methods and results, as well as analysis results, measurement data, and case studies. We encourage you to take a look. [Contents] ■ DSC Measurement of Silicone Rubber (Low-Temperature Measurement) ■ Quantification of Carbon Black by Thermogravimetric Measurement ■ Estimation of Deformation and Fracture of Plastics under Compressive Stress ■ Long-Term Deformation Prediction by DMA *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In this case study collection, we will introduce examples related to "thermal analysis." Starting with "DSC Measurement of Chocolate 1 (Estimation of Crystal Type)," we also include "DSC Measurement of Chocolate 2 (Comparison Between Products)" and "DSC Measurement of Chocolate 3 (Differences in Melting Behavior)," along with their objectives, methods, and results. Additionally, we present analysis results, discussions, and other analytical examples. We encourage you to read it. [Contents] ■ DSC Measurement of Chocolate 1 (Estimation of Crystal Type) ■ DSC Measurement of Chocolate 2 (Comparison Between Products) ■ DSC Measurement of Chocolate 3 (Differences in Melting Behavior) ■ DSC Measurement of Chocolate 4 (Verification of Optimal Production Conditions) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

Thermal analysis is a technique for measuring the temperature dependence of certain physical properties of a substance while changing its temperature. Examples of methods: ● DSC: Can be used for analyzing the melting, glass transition, thermal history, crystallization, curing, Curie point, etc., as well as measuring specific heat. ● TG/DTA: Can be used for analyzing moisture content, ash content, decomposition, oxidation, and evaluating heat resistance. ● TMA: Can be used for measuring the expansion rate, glass transition, softening point, etc. In this collection of case studies, we will introduce examples of 'thermal analysis.' We encourage you to read it. [Contents] ■ The influence of atmosphere in TG-DTA measurements ■ Melting measurement of cocoa butter (introduction of peak separation function) ■ Introduction of temperature-modulated DSC method ■ Gelatinization of rice and noodles There are many other cases not included. We also have experienced technicians in our thermal analysis laboratory who can meet directly. Please feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In this case study collection, we will introduce examples related to "cross-sectional observation and structural analysis." Starting with the analysis case of "Evaluation of aluminum sputter films using EBSD," we also include numerous examples such as the purpose, methods, samples, and results of "Cross-sectional processing of micro areas by ion milling," and the purpose, methods, and results of "Residual stress measurement of solder cross-sections." Additionally, we present orientation evaluations, cross-sectional observation results, and measurements. We encourage you to read through it. 【Contents】 ■ Evaluation of aluminum sputter films using EBSD ■ Cross-sectional processing of micro areas by ion milling ■ Residual stress measurement of solder cross-sections ■ Residual stress measurement of wire ■ Cooling (cryo) ion milling cross-sectional processing *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

This case study collection introduces examples related to "cross-sectional observation and structural analysis." It includes numerous analytical cases covering the objectives, methods, and results of "metallic structure observation of wire (spring material)," "phase analysis of duplex stainless steel," and "evaluation of semiconductor insulating films using STEM-EDS." Additionally, it presents observations, phase analyses, insulating film analyses, and measurements, among other topics. We encourage you to read it. [Contents] ■ Metallic structure observation of wire (spring material) ■ Phase analysis of duplex stainless steel ■ Evaluation of semiconductor insulating films using STEM-EDS ■ EBSD measurement of samarium cobalt magnets ■ Analysis of connector terminal contact defects using STEM ■ Cross-sectional observation of biological samples (Morpho butterfly scales) *For more details, please refer to the PDF document or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration

In this case study collection, we will introduce analysis examples using "AFM: Scanning Probe Microscopy." [Contents] ● Method and results of "Structural analysis and elastic modulus measurement of food (somen)" ● Features and analysis examples of "Conductive measurements of AFM in a vacuum" ● Features and analysis examples of "Conductivity evaluation of material surfaces using AFM" ● "AFM observation of polymer materials (smoothing by microtome)" We conduct various analyses using AFM, which is one of our strengths. We hope you will take a look. There are many other examples not included here. *For more details, please refer to our other PDF materials or feel free to contact us.

Added to bookmarks

Bookmarks listBookmark has been removed

Bookmarks listYou can't add any more bookmarks

By registering as a member, you can increase the number of bookmarks you can save and organize them with labels.

Free membership registration